5-10 LY Installation and Maintenance for LY 1001, LY 2001 and LY 3001 LMAIM1501

5.8 Mechanical Stops

5.8.1 Setting the CLOSED Mechanical Stop on the LY 1001

Table 5.5 – Mechanical Stop Set Screws

Unit Mechanical Stop Set Screw

Type Set Screw Size Size

LY 1001 3/8-16 x 1.25” 3/8-16 x 0.375"

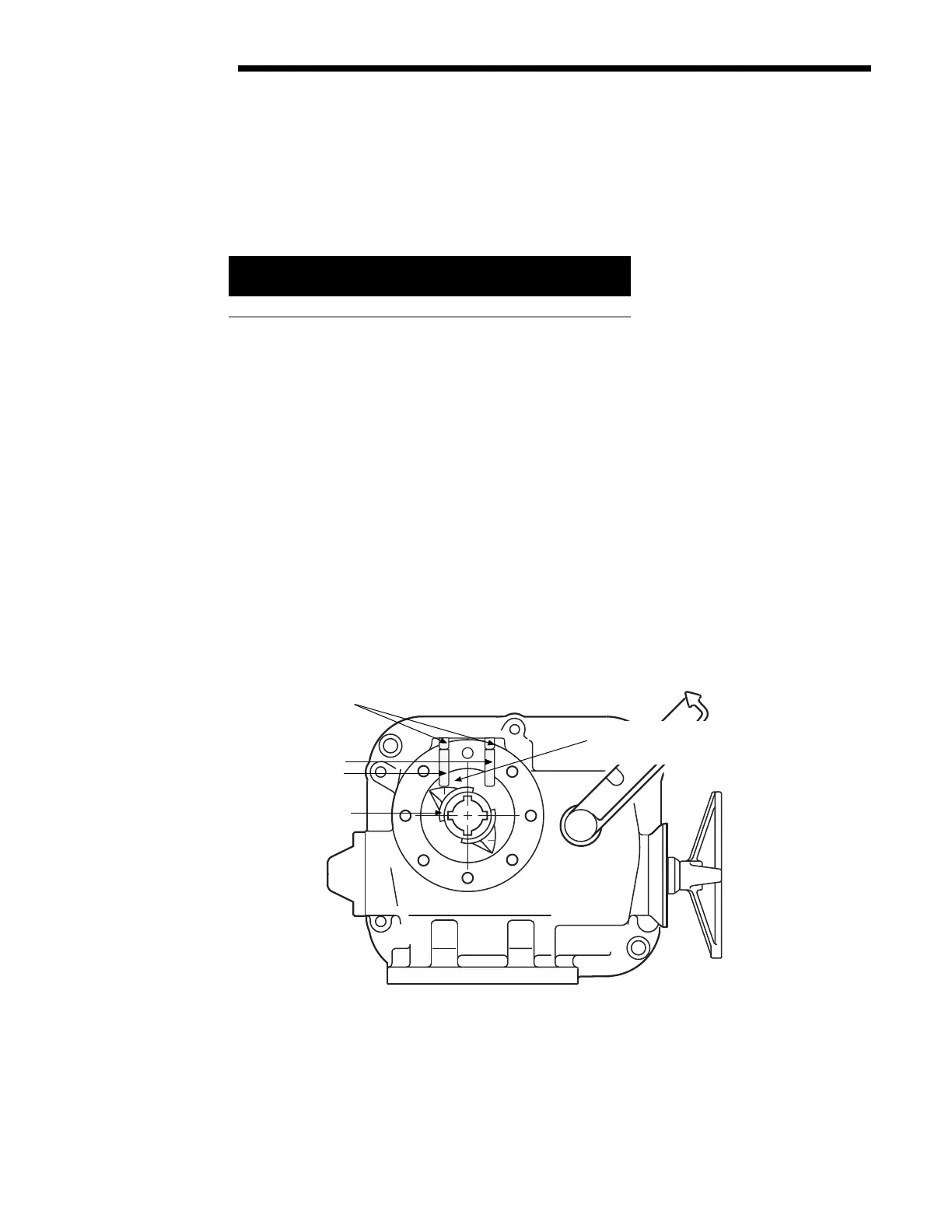

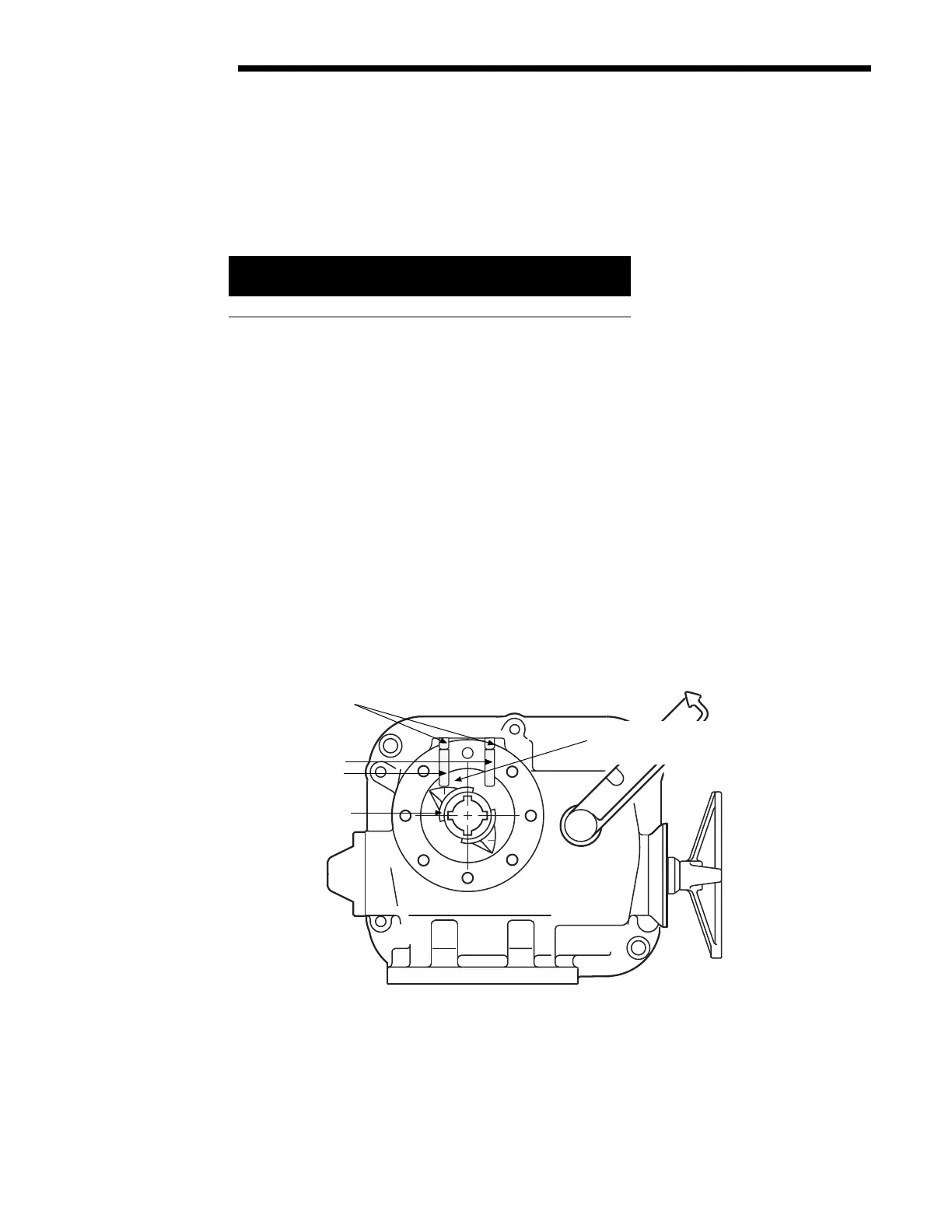

Piece numbers refer to Figure 5.10.

1. Set CLOSE Mechanical Stop Set Screw (piece #58) by removing the Set Screw (piece #59).

2. Using the Handwheel, turn the valve to the CLOSE position. Make sure the valve is fully seated before setting

the mechanical stop.

3. Rotate Mechanical Stop Set Screw (piece #58) in the CW direction until contact with the Torque Nut (piece

#32) occurs. (See Figure 5.9.)

4. Back-off Mechanical Stop Set Screw (CCW direction) approximately 1-1/2 turns.

5. Reinstall Set Screw (piece #59).

6. Manually operate the actuator through the close limit to assure setting is correct.

NOTE: The Mechanical Stops are intended to protect the equipment from overtravel if a Limit Switch fails. The

valve should not torque-out against the Mechanical Stop Set Screw during normal OPEN/CLOSE cycles.

Figure 5.10 – Mechanical Stop Set Screw Adjusted to Torque Nut Contact Point on LY 1001

#59 Set Screw

#58 Mechanical

Stop Set Screw

#32 Torque Nut

Torque Nut &

Mechanical Stop Screw

positioned at contact point

CCW to Open

Mechanical Stop

Set Screws

OPEN CLOSED

LY 1001 Bottom View

Flow Control Division

Limitorque Actuation Systems

Loading...

Loading...