SMB/SB Installation and Maintenance Manual 140-11000 • July 2003

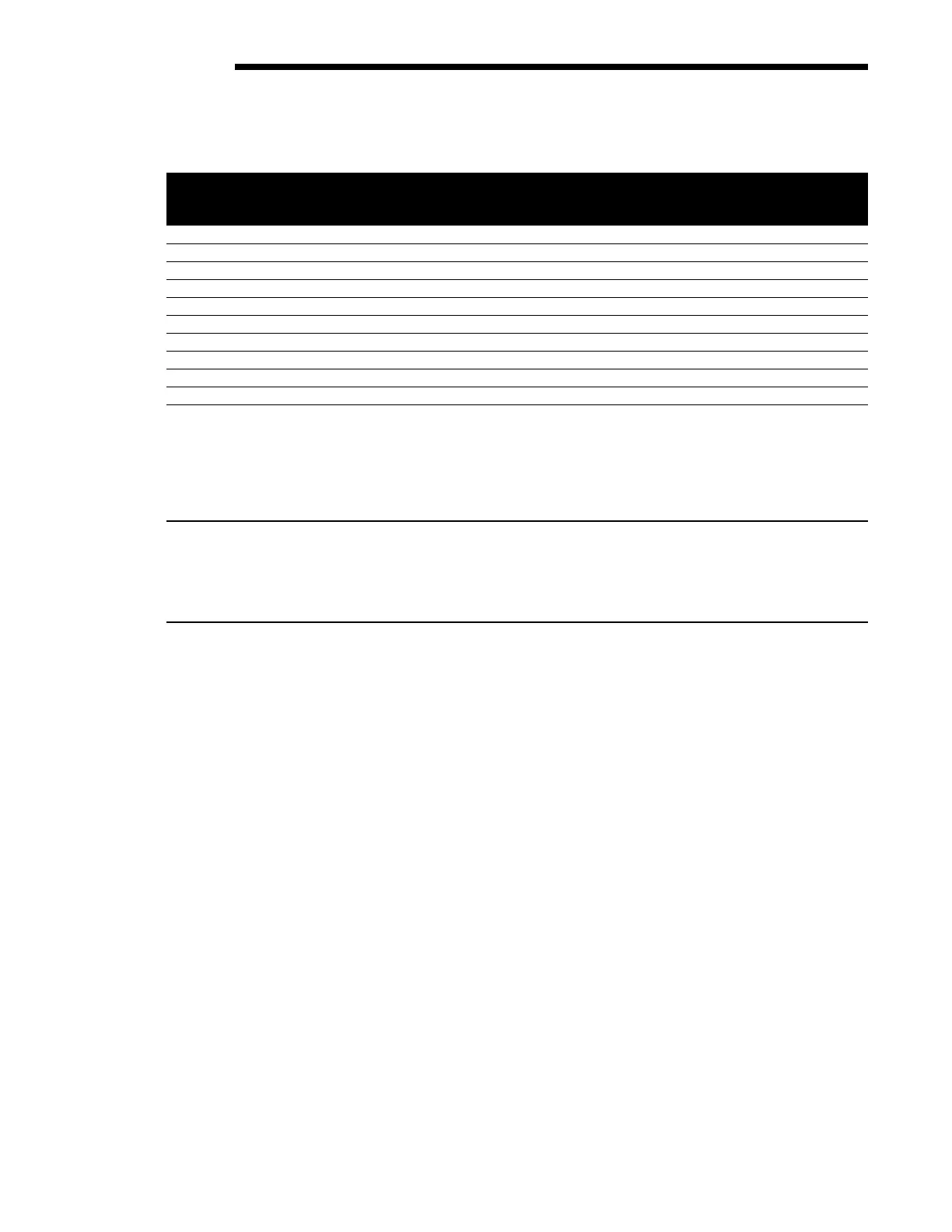

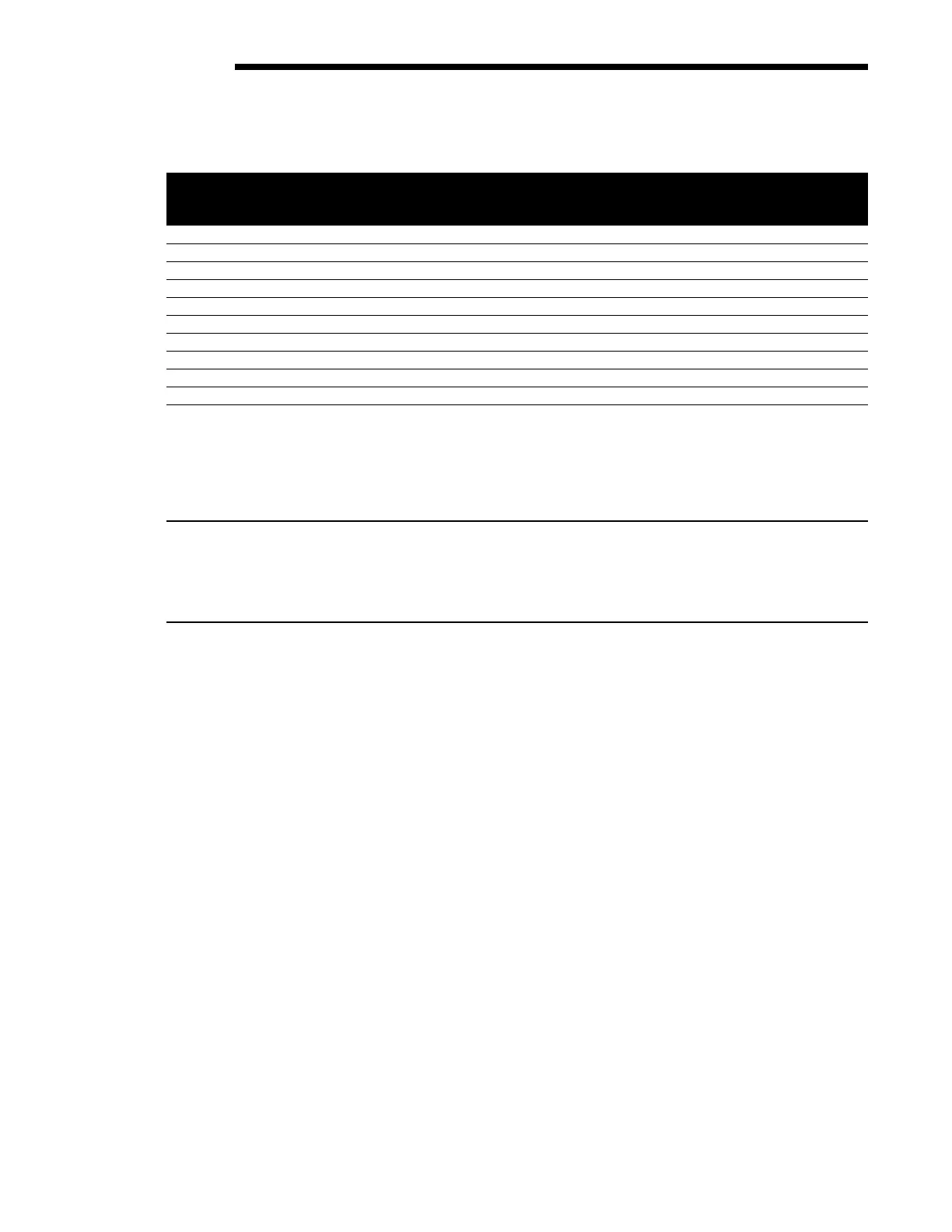

Table 6.1 – Approximate Volume and Weights of Lubricants

Actuator Size Approximate Approximate

Volume Weight

gallons liters lbs. kg

SMB/SB/SBD-000 .50 1.9 3.5 1.6

SMB/SB/SBD-00 1.0 3.8 8.5 3.8

SMB/SB/SBD-0 1.5 5.7 12.0 5.4

SMB/SB/SBD-1 2.1 7.9 17.0 7.7

SMB/SB/SBD-2 3.0 11.4 24.0 10.9

SMB/SB/SBD-3 6.0 22.7 50.0 22.7

SMB/SB/SBD-4 9.4 35.6 75.0 34.0

SMB-4T 8.7 32.9 70.0 31.8

SMB-5T 10.0 37.8 80.0 36.4

SMB-5 11.2 42.4 90.0 40.9

6.3.3 Minimum Lubricant Qualities Required

CAUTION: Do not mix lubricants of a different chemical base. Mixing lubricant bases may cause lubricant properties to be

ineffective.

CAUTION: Do not add a different lubricant to an actuator unless it consists of the same soap base as the existing lubricant unless

you have received lubricant manufacturer approval.

The standard lubricants used by Limitorque have been proven to be extremely reliable over the years of service. Other lubricants

may be used in place of the standard. Limitorque does require the following lubricant qualities as a minimum.

The lubricant must:

• contain an “EP”additive.

• be suitable for the temperature range intended.

• be water and heat-resistant and non-separating.

• not create more than 8% swell in Buna N or Viton.

• not contain any grit, abrasive, or fillers.

• comply with Slump-prefer NLGI grades 00 to 1.

• not be corrosive to steel gears, ball or roller bearings, or yellow metals (bronze, brass, or copper alloys).

• have a dropping point above 316˚F (158˚C) for temperature ranges of -20˚F (-29˚C) to 150˚F (66˚C).

6-3

Flow Control Division

Limitorque Actuation Systems

Loading...

Loading...