___________________________________________________________________________________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________

Form 403595 Page Number - 5

METER INSTALLATION

Relieve System Pressure

Grounding

Explosion and Fire

Movement of fluids through the dispensing

system creates static electricity. Static electricity

can cause volatile fumes resulting in an

explosion and fire. The dispensing system must

be grounded.

1. Grounding reduces the risk of static

sparking. Ground all system components

according to local, state, and federal

codes. Consult the pump user's manual

and other system components to ground

the following:

2. Pump: follow manufacturer's

recommendations

3. Air and Fluid Hoses: use only grounded

hoses

4. Air Compressor: follow manufacturers

recommendations

5. Fluid Supply Container: follow the local

code

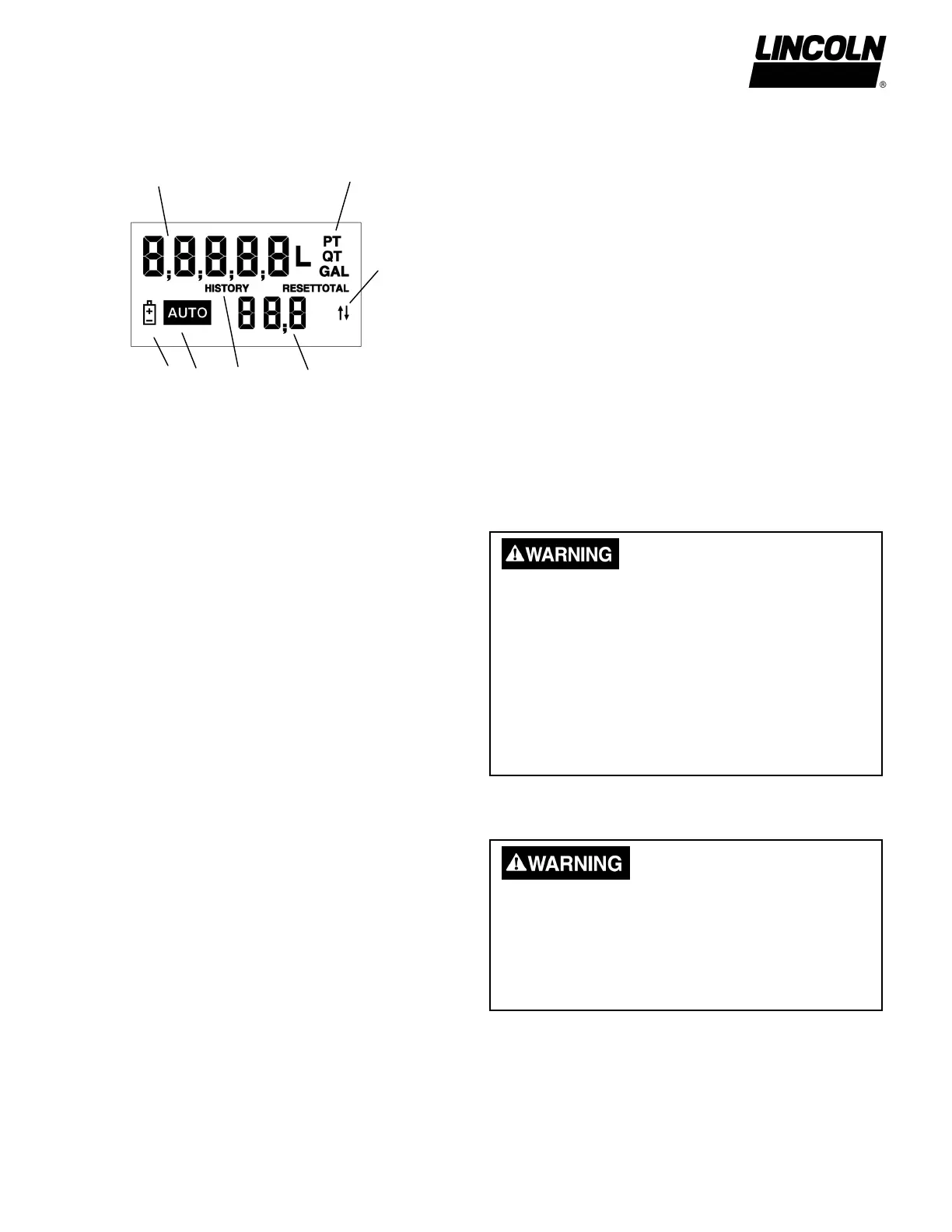

1. Displays re-settable total, accumulated

total and Scale Factor

2. Displays Unit of Measure

3.

rrows flash when RF communication is in

progress with the keypad

4. Preset Batch quantity

5. History Icon

6. AUTO is an indicator of being in EPM

mode

7. Low Batter

Icon

LCD Dis

la

7

6

4

1

3

5

LCD Display

Pressurized Equipment

This equipment stays pressurized until the

pressure is manually relieved. To reduce the risk

of injury from fluid spray from the meter follow

the Pressure Relief Procedures when you:

• Are instructed to relieve pressure

• Stop dispensing

• Check, clean, or service any system

equipment

Clean or install nozzles

1. Turn off the power supply to the pump

or close the shutoff valve.

2. Dispense any fluid in the system into a

waste container by opening the

meter(s).

3. Open all bleed-type master air valves

and fluid meter(s) in the system.

4. Leave the meter(s) open until ready to

pressurize the system.

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Loading...

Loading...