33

Troubleshooting

Problem: Leakage past the packing gland drive shaft housing from internal metering chamber.

Probable Cause: Internal seal of the packing gland assembly is worn. Replace packing gland and O-Ring seal.

Operating Note: Two common causes of packing gland leakage are thermal expansion and hydraulic shock. If two

valves in a piping system (on either side of the meter) are closed at one time, and if the temperature rises as little

as 1ºF in the system, it could result in a rise in pressure (70 psi for every 1°F) within the system that would exceed

the working pressure rating of the meter. To avoid this hazard caused by thermal expansion, a pressure-relief

valve must be installed in the system. Hydraulic shock occurs when a large volume (mass) of liquid is moving

through a pipe line at some flow rate and a valve is suddenly closed. When the flow is stopped, the entire mass of

liquid in the piping system acts as a battering ram causing a shock effect within the meter. The greater the mass,

length of line, and/or velocity, the greater the hydraulic shock. Since the valve is usually located at the meter outlet,

the meter housing, packing gland and the meter internal components receive the full impact of such hydraulic

shock. To prevent this hazard, a slow closing, two-stage valve should be used with the meter. On those systems

where mass length of line, etc. are of such magnitude as to preclude elimination of hydraulic shock with the use of

a two-stage valve, an impact absorbing or cushioning device should be used.

Problem: Leakage from the cover gasket.

Probable Cause: Gasket has been damaged due to shock pressure, thermal expansion, or cover bolts that have not

been sufficiently tightened.

Problem: Breaking teeth on rotor timing gears.

Probable Cause:

1. Starting or stopping flow in the meter too rapidly.

2. Pump bypass not adjusted properly.

3. Shock due to start-up of an empty system. When liquid is introduced, shock can occur if not started slowly.

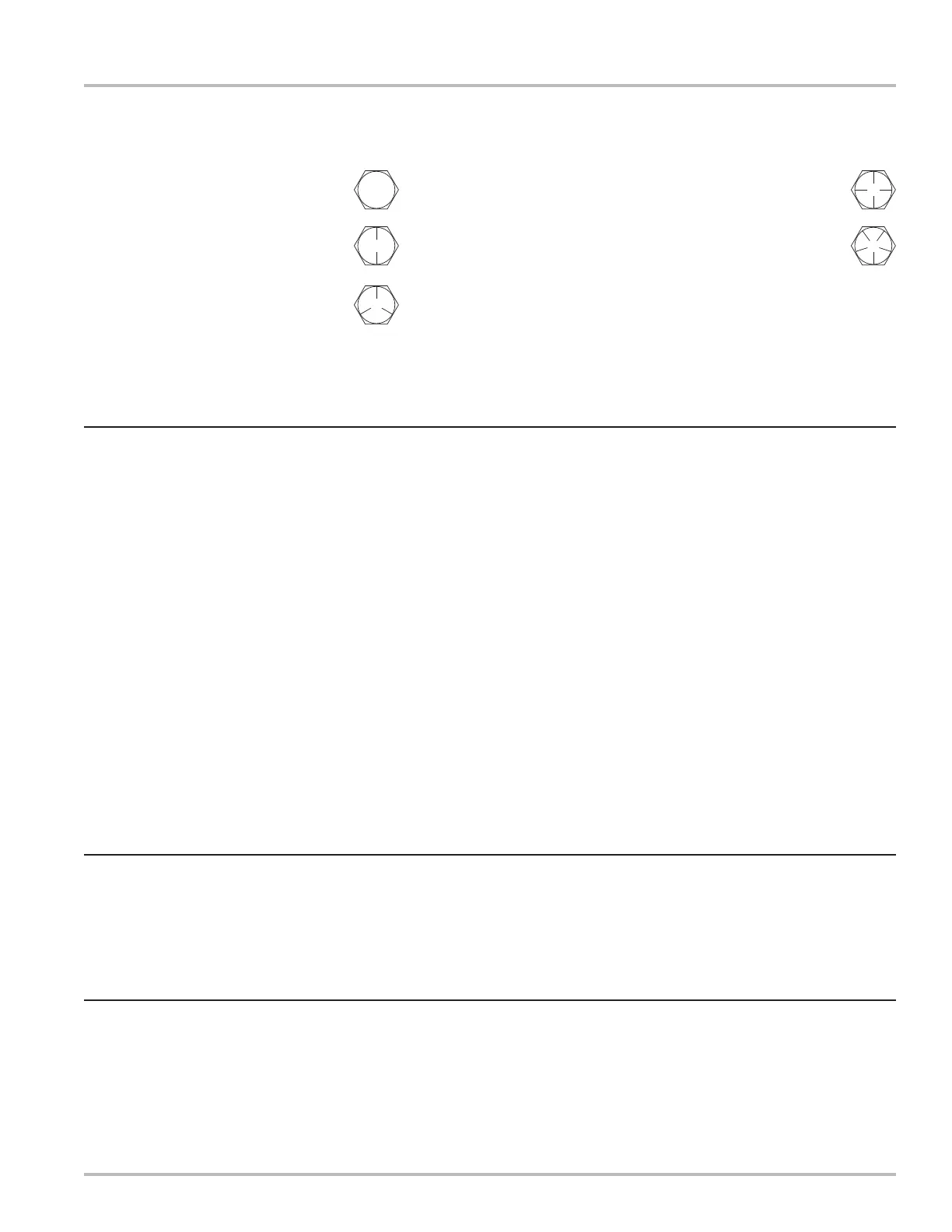

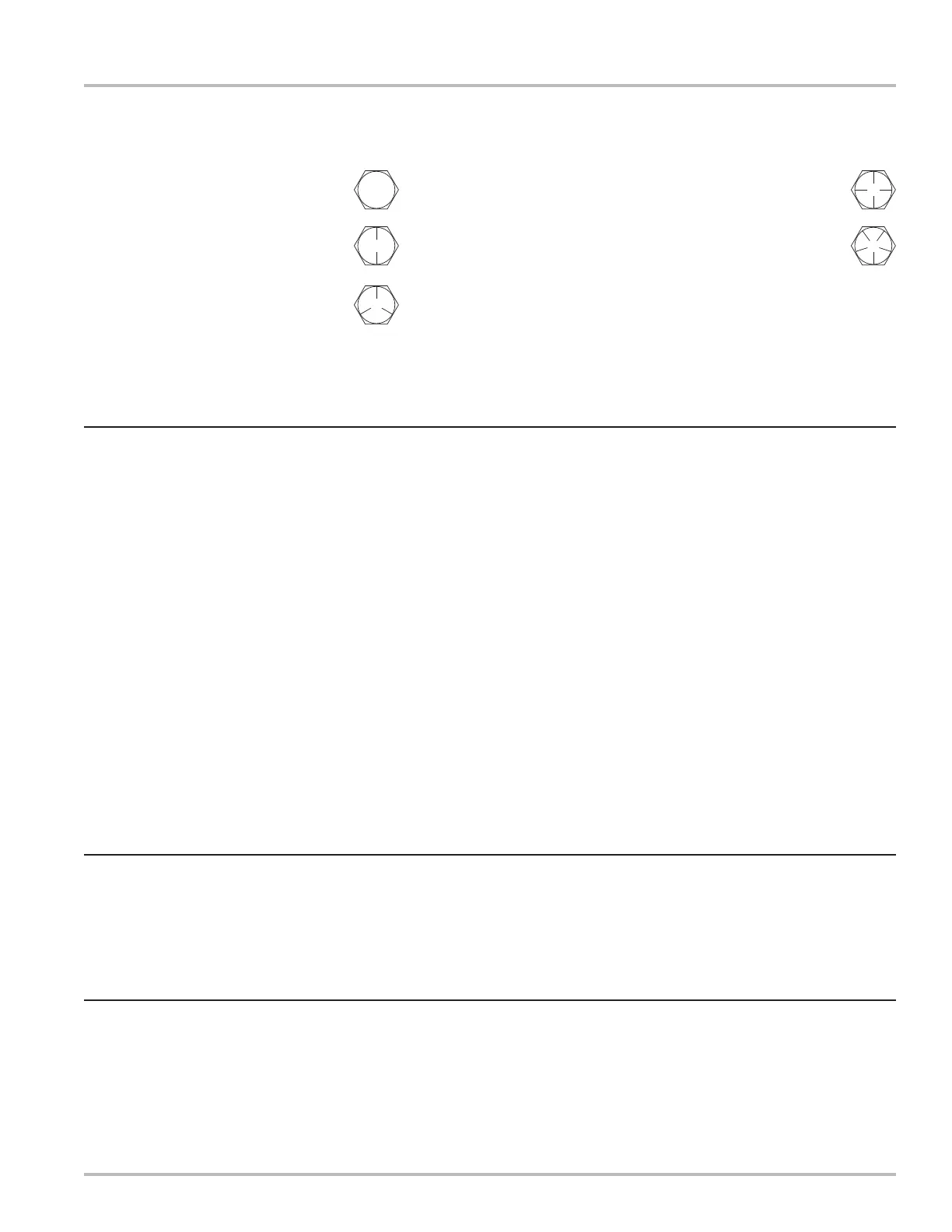

Identification of Bolt Grades

Grade 0, 1, & 2

(No Markings)

Grade 3

2 radial dashes, 180º apart

Grade 5

3 radial dashes, 120º apart

Grade 6

4 radial dashes, 90º apart

Grade 7

5 radial dashes, 72º apart

Grade 8

6 radial dashes, 60º apart

Troubleshooting

Loading...

Loading...