CHAPTER 6: HYDRAULICS 6-3

ALPHA 538/552

2. DESCRIPTION OF THE ELEMENTS

2.1. Hydraulic pump motor

The hydraulic pump is powered by 3 phases 220V AC. The hydraulic pump powers on immediately when

conditions below satisfied:

- The bar feed system switched to automatic mode.

- The guide channel is closed.

- The pusher position is located between home position the “2nd” of parameter P06.

For further information, refer to “Chapter 3. SETTING INTO OPERATION” and “Chapter 4. ELECTRICS”.

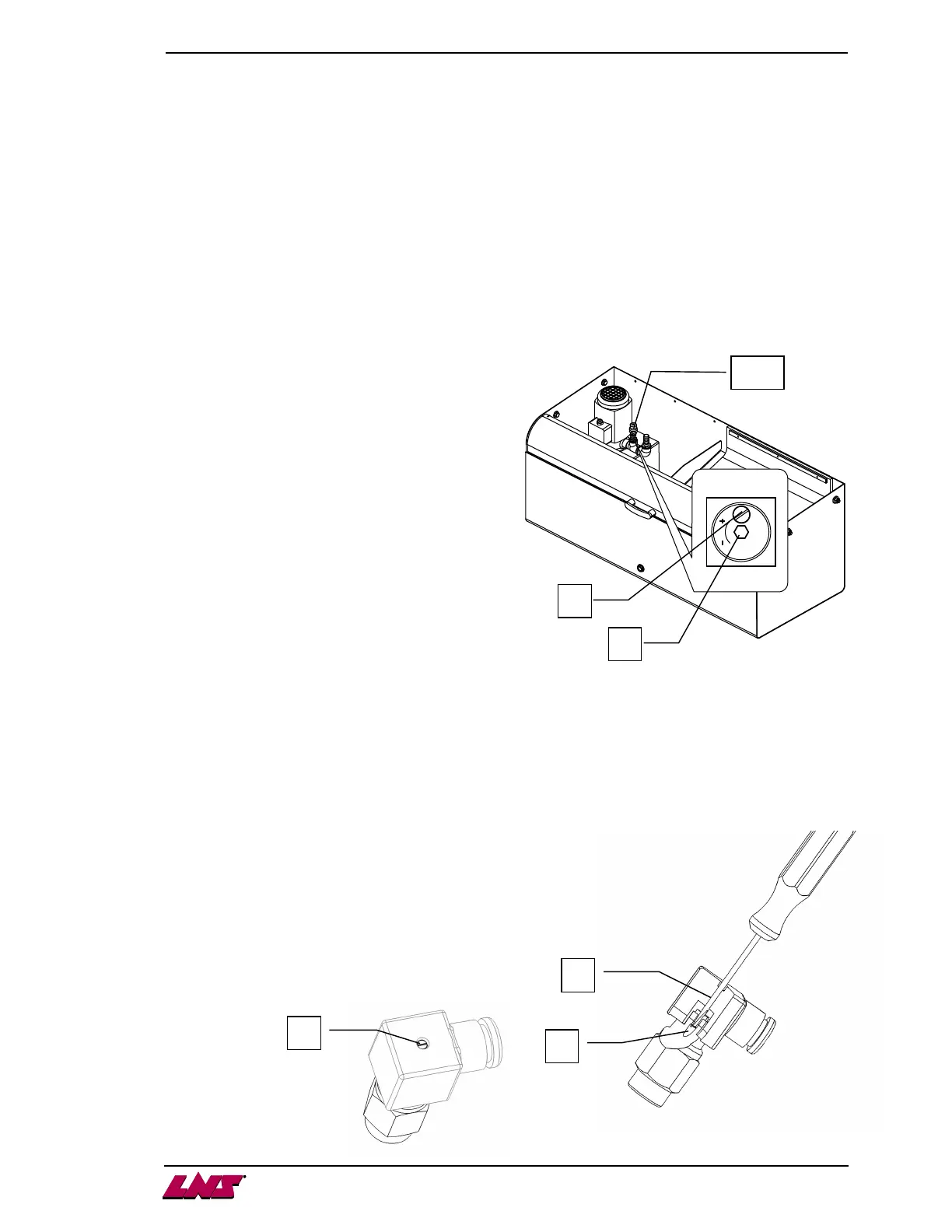

2.2. Oil pressure switch

The pressure is constantly monitored by a pressure

switch set at the factory at a point of release of 0.5

bar. There are 2 types of switches that were fitted to

the bar feeder. It may be adjusted, if necessary, as

follows:

Settings for square body style:

1. With a screwdriver, unscrew the locking

screw (A).

2. Insert a hex head wrench (5mm) into the

center of the pressure switch (B).

By turning clockwise, the release of the

pressure switch will take place at a pressure

higher than the original setting. Turning in the

opposite direction, will produce the reverse.

PLC input X12 will show the condition of the

switch, and can be monitored to assist for setting.

3. When the adjustment is completed, retighten

the locking screw (A).

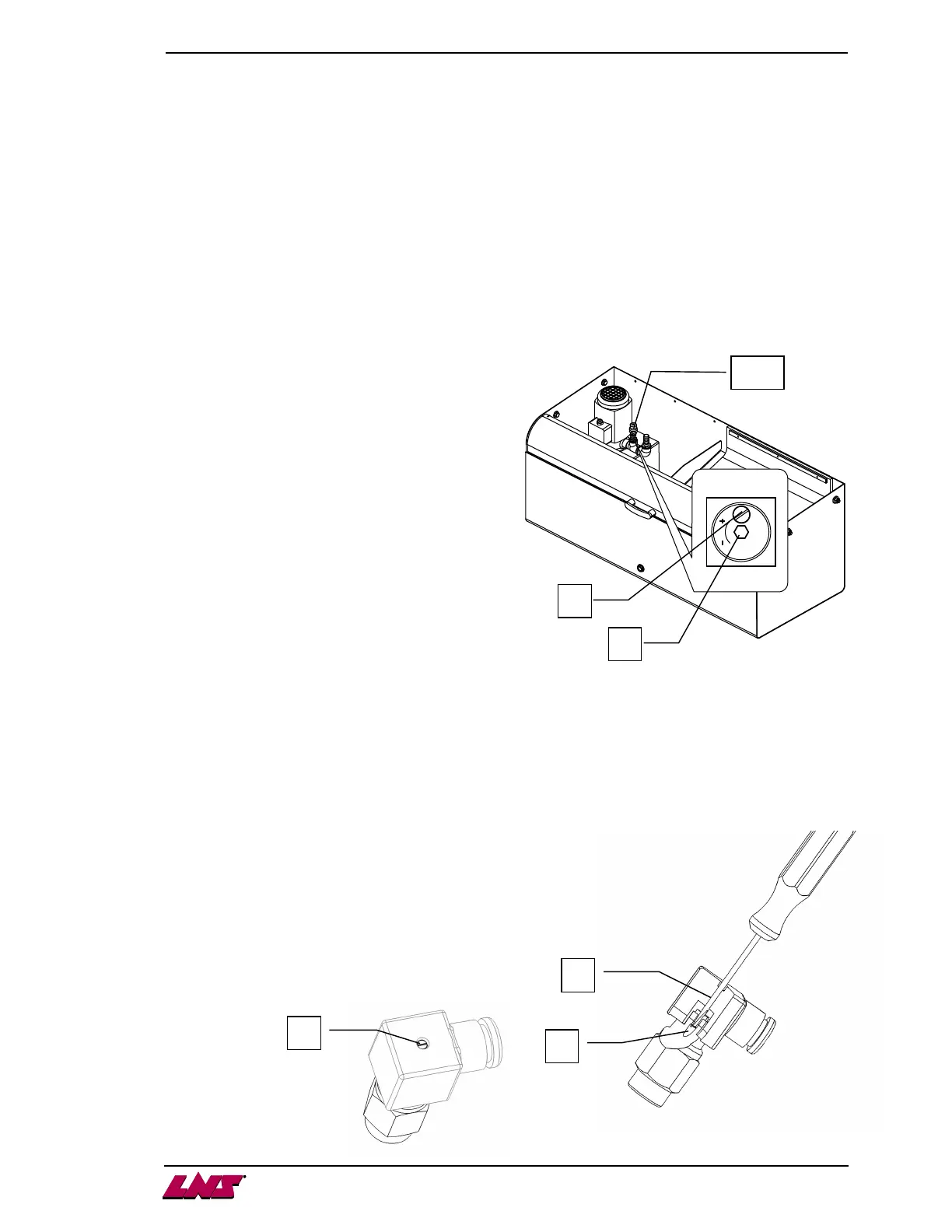

Settings for hex body style:

1. With a screwdriver, unscrew and completely remove the cap screw from

the plug, leaving the plug installed on the switch (C).

2. Insert a small diameter flat blade screwdriver (ø2-2.5mm) into the center

of the pressure switch (D) where the cap screw was located. The adjuster is

located inside the body of the switch (E). By turning

clockwise, the release of the pressure switch will take

place at a pressure higher than the original setting.

Turning in the opposite direction, will produce the

reverse. PLC input X12 will show the condition of the

switch, and can be monitored to assist for setting.

3. When the adjustment is completed, reinstall the cap

screw into the plug and tighten (C).

A

B

SP2

D

E

C

Loading...

Loading...