CHAPTER 7: OPERATION 7-7

ALPHA 538/552

3. PUSHER

Please read the safety instructions provided at the beginning of this manual before

handling the following devices.

To change the guiding elements and the pusher, the procedure in the start-up manual

must be applied.

3.1. Description

The pusher is used to push the bar stock forward through the spindle of the lathe, until the remaining

material is too short to machine another part. Additionally, depending on the machining process, the

pusher can be equipped to pull back the remnant and evacuate it through the barfeed.

The pusher diameter is 1 mm smaller than the guiding elements’ diameter. This ensures the best bar

guiding.

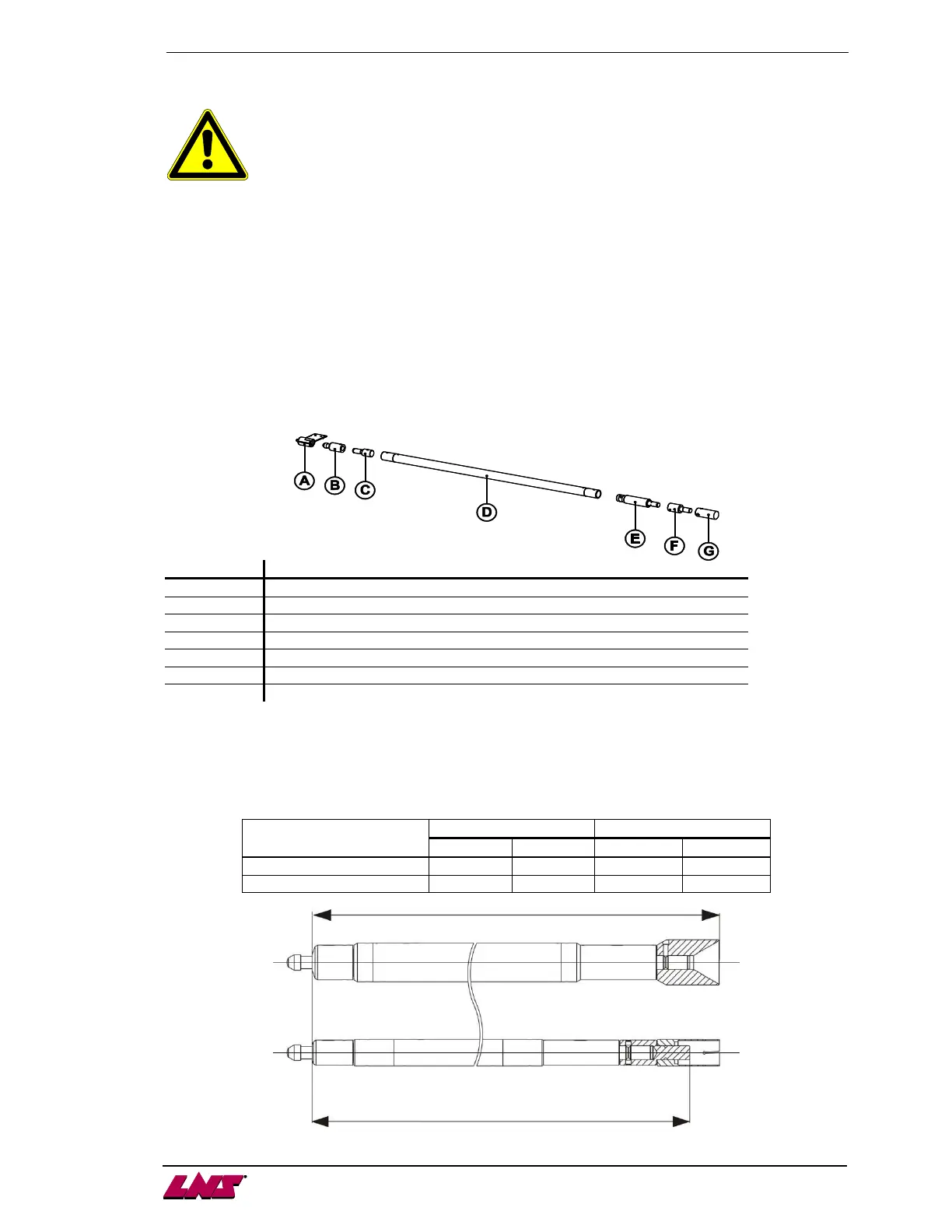

When the new bar loading cycle is started, one bar is loaded into the guiding zone. The loading flag (A),

which is connected to the servo drive through the chain, moves the bar stock into the spindle. When the

bar is out of interference, the loading flag retracts, the guiding zone closes. The pusher assembly swings

down and connects to the loading flag. The pusher moves forward to finish the bar stock positioning to

the top cut position.

Connecting part to the loading flag

Remnant evacuation:

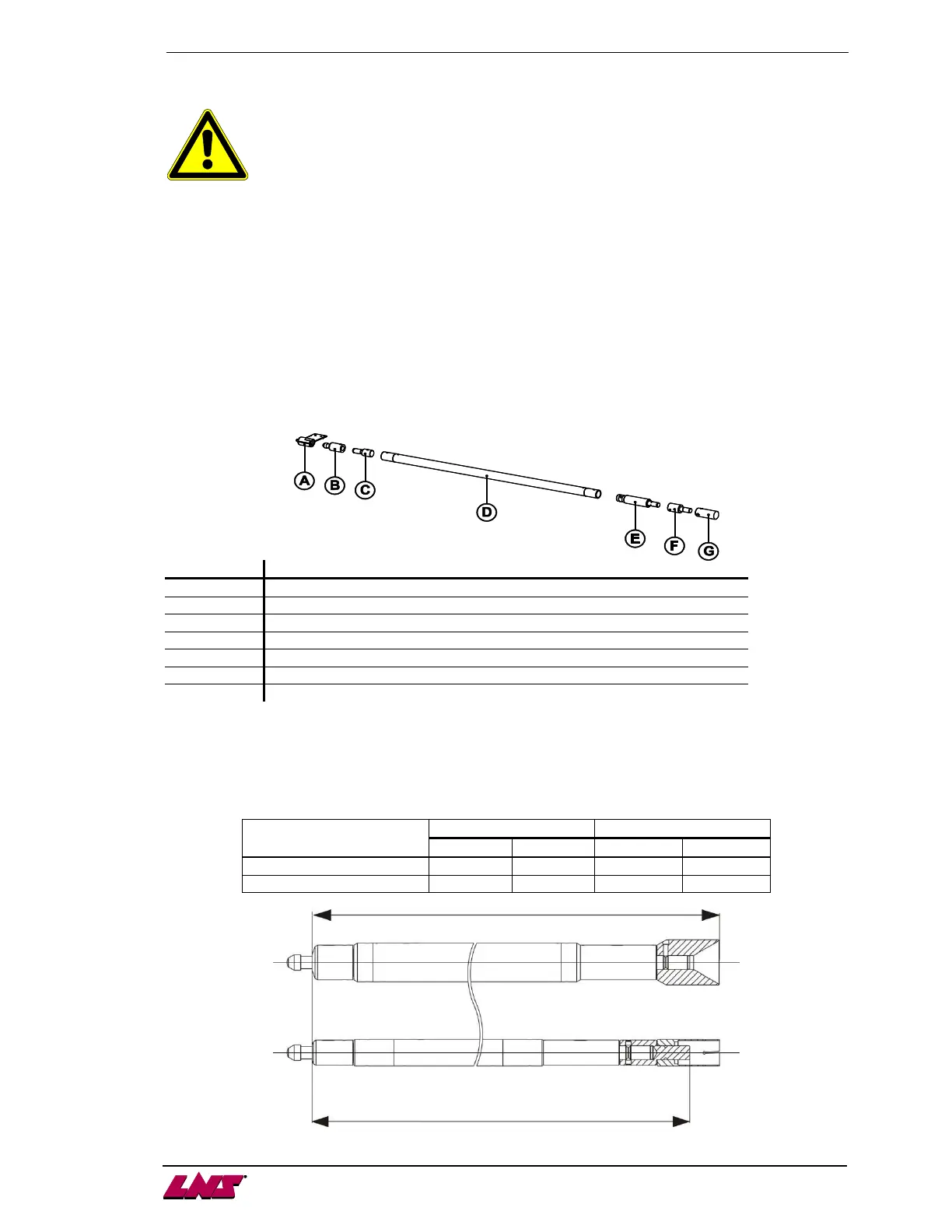

- Through the lathe : pusher equipped with rotating sleeve and cone tip

- Through the barfeed: pusher equipped with rotating sleeve and collet

Depending on the spindle length, 2 pusher lengths are available:

Pusher version

Cone Collet Cone Collet

LP

Cone

Collet

Loading...

Loading...