CHAPTER 7: OPERATION 7-11

ALPHA 538/552

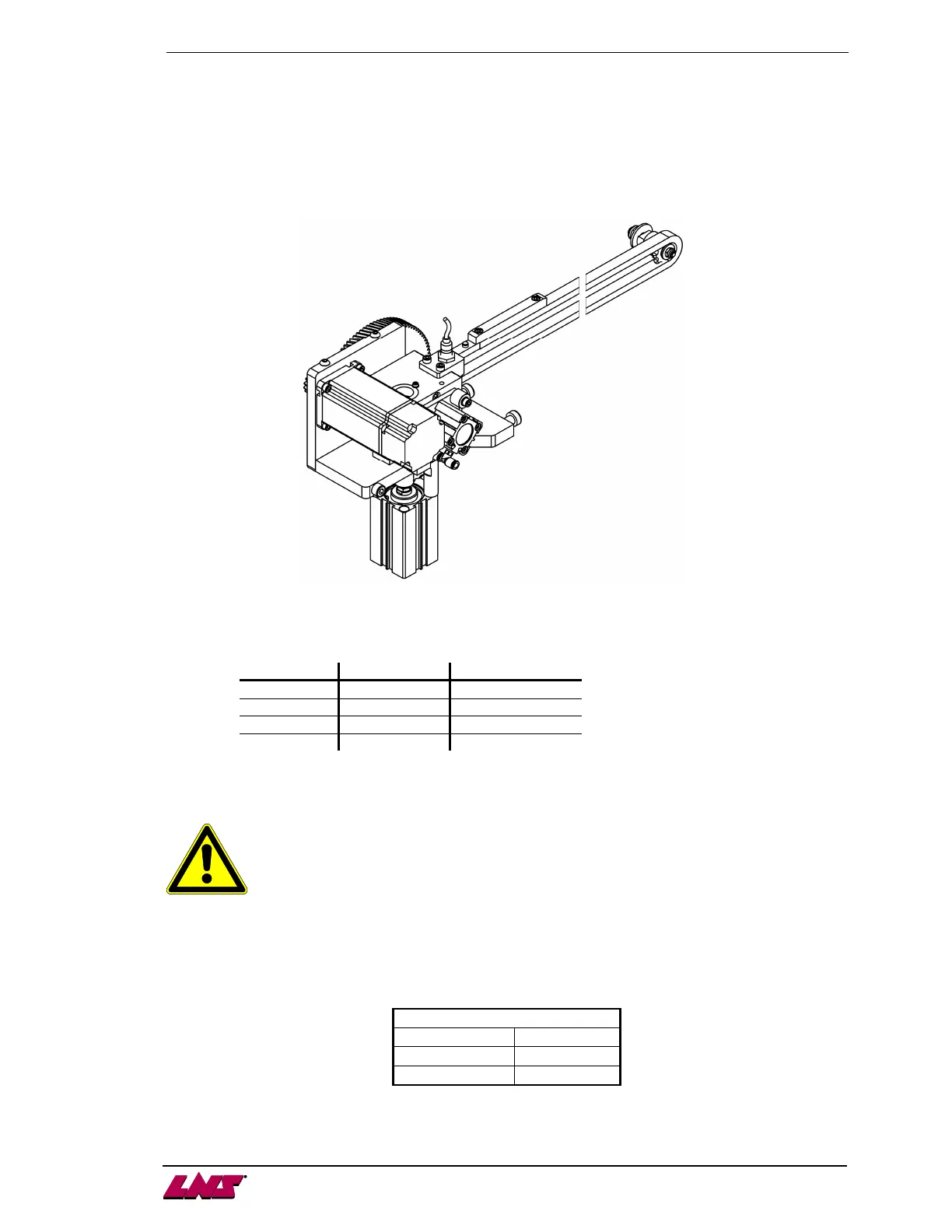

5. CHAIN DRIVE

5.1. Description

The chain drive is controlled by a servo drive (M2) piloting all of the forward and backward movements of

the pusher, the insertion and extraction movements of the bar in the collet.

5.2. Layout of the elements

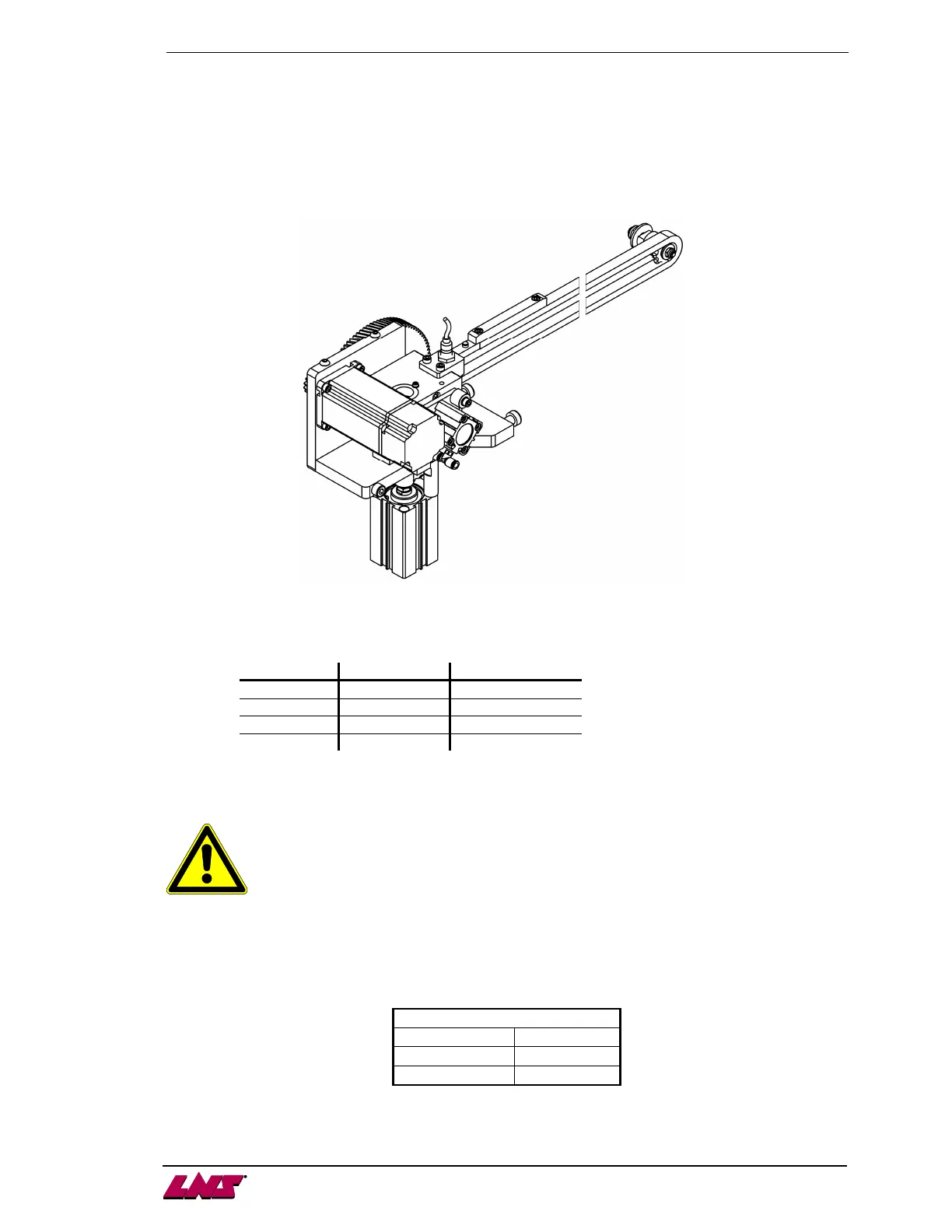

5.3. Chain

It is possible that after a certain amount of use, the Chain (B) needs to be tightened.

Should the Chain tension need adjustment, make sure that while adjusting, the Chain

remains under tension in order not to lose the reference point. Should the reference point

be lost, call for service assistance.

Procedure:

· Switch the bar feeder to STOP mode (remote station).

· Open the main access cover.

· Loosen the lock screws (A) of the adjusting bearing (B).

· With a torque wrench, apply a torque on the side screw (C) according to following chart).

Chain tension

3M 0.5 Nm

12' 0.5 Nm

4M 0.5 Nm

· When done, tighten the lock screws (A) of the adjusting bearing (B).

Designation

Article No Description

A B14120203 Servo motor

B 11.1311.8850 Chain for 12’ unit

C B18120401 Reference switch

D - Smart booster

Loading...

Loading...