CHAPTER 8: OPERATION 8-10

ALPHA 538/552

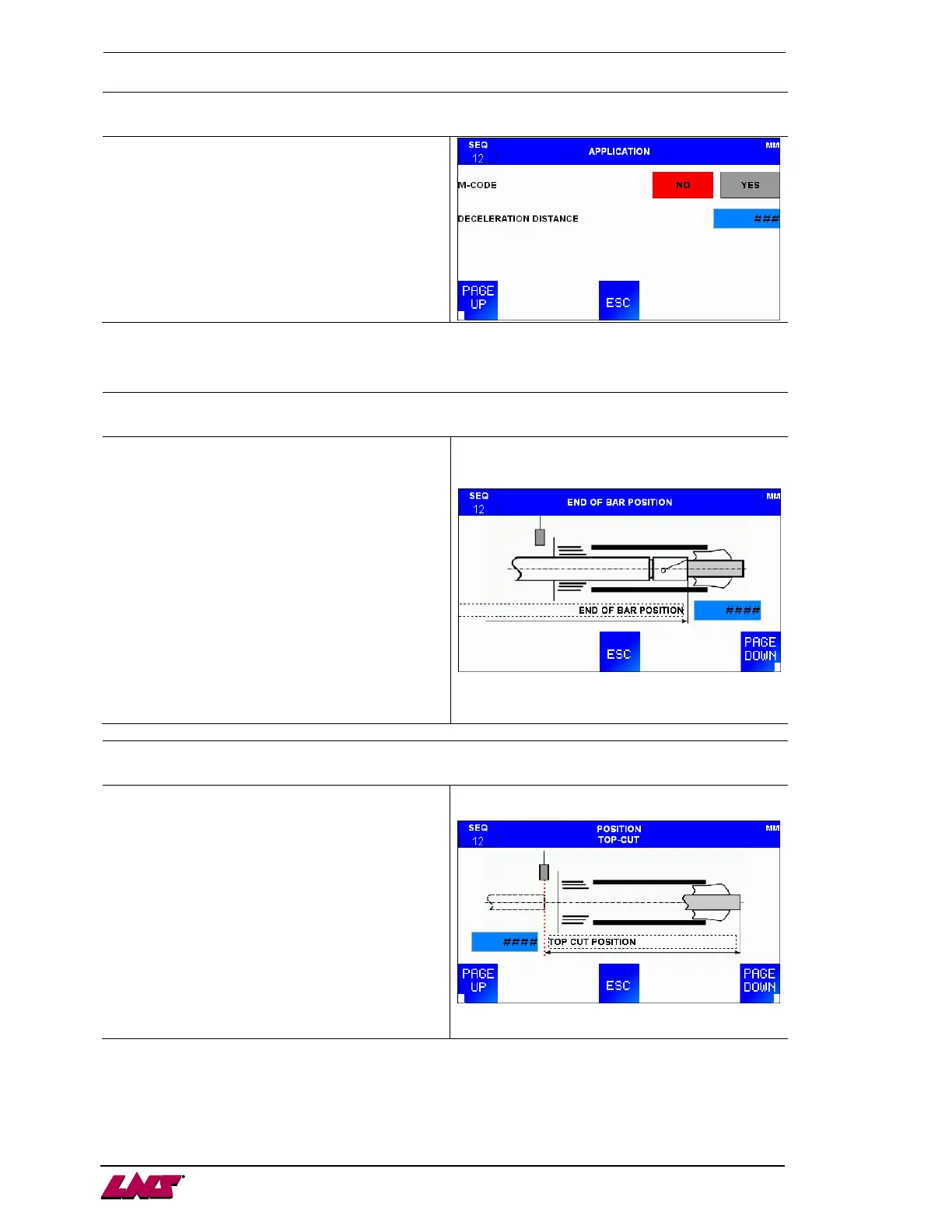

Application M-code & deceleration distance

M-code

During production time, the lathe issues an M-

Code signal (A4). The bar feed will push the bar

into position and emit a signal over the R2 relay to

reset the M-Code and the lathe will then be able to

continue working.

Deceleration distance

Distance in which the pusher as to slow down

5.4. Position parameters

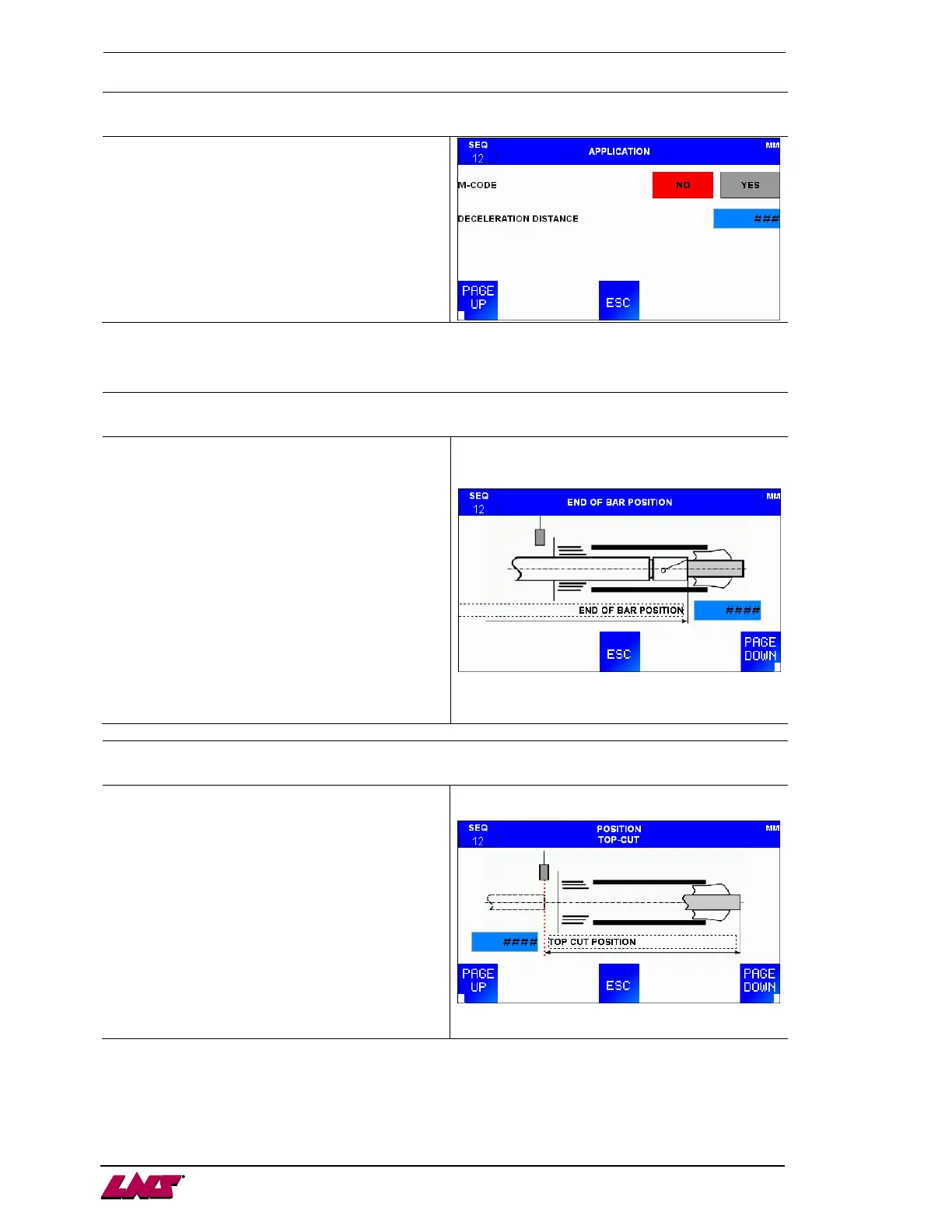

Position: End of bar

End of bar

(may be not visible)

The end of bar position determines the moment

when the barfeed enters the loading cycle.

Usually, the end of bar position is adjusted as

closely as possible behind the clamping system of

the lathe (approximately 5 mm or a 1/4" behind the

chuck jaws or collet pads).This will provide

minimum bar stock remnant.

Regardless of the length of the bars, or parts, the

end of bar position is always the same. In very

special cases, a different end of bar setting needs

to be selected.

Position: Top cut

Top-cut position

During the loading cycle, the bar is automatically

loaded and positioned into the spindle, outside the

clamping device of the lathe (chuck or actuator).

This positioning corresponds to a value (Z)

programmed by the operator, which is equal to the

distance between the measuring cell and the

position of the material in the lathe clamping

device.

With this system, the setting is the same for any

bar length.

Loading...

Loading...