6. Autostart Operation

– Start and stop via transducer level

• Transducer with backup switches

– Start and stop via transducer level

– Switches as backup start and stop if there is a transducer failure

• Scheduler

• Timed run

– Manually started

– Automatically stopped by countdown timer

– Can maintain a level while running

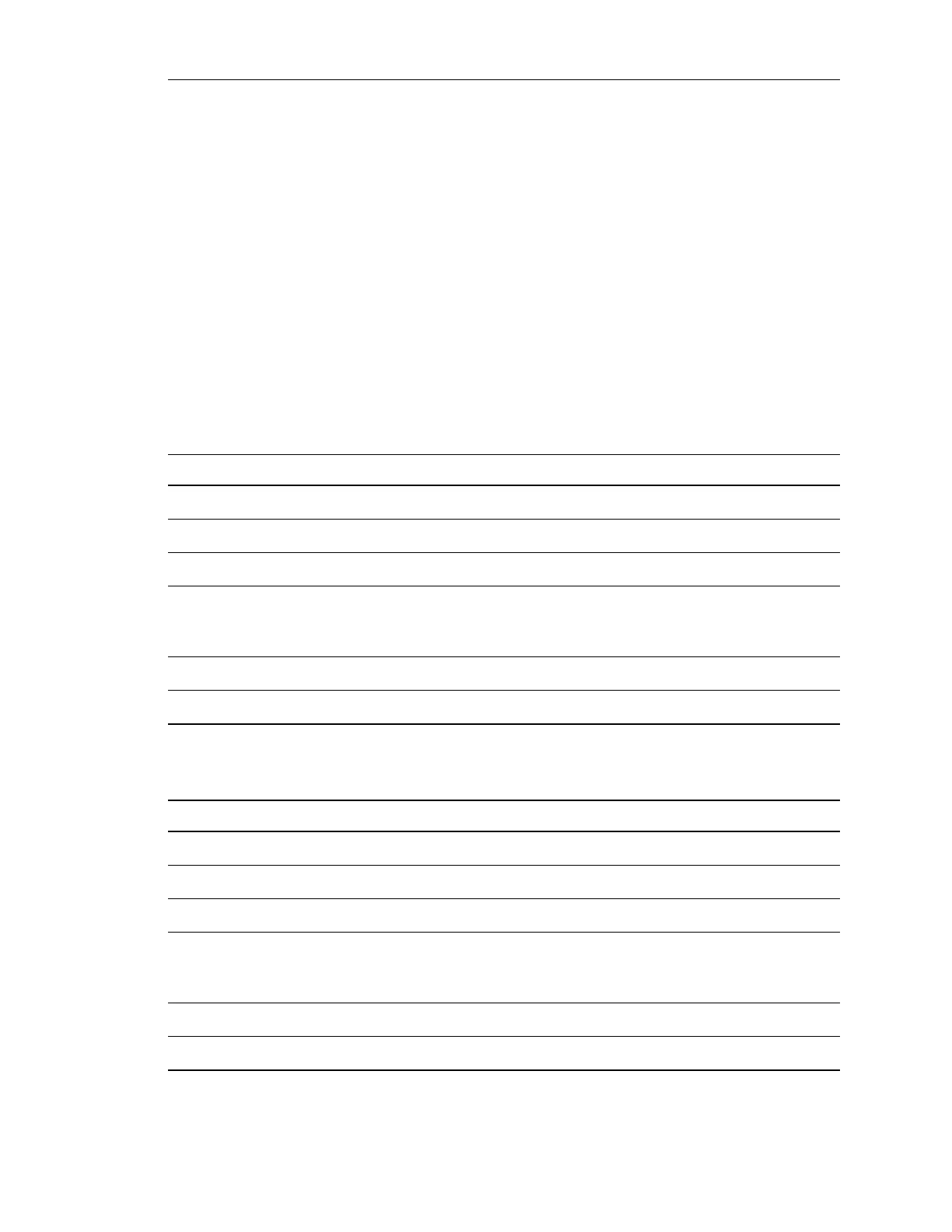

The following table describes the Start/Stop events when behavior operation is set to ”High to Low”

(switches/floats are normally open):

Start/Stop Events Engine Starts When Engine Stops When

Single Switch SW1 is closed SW1 is open

Dual Switch

SW1 and SW2 are both closed

SW1 and SW2 are both open

Transducer Input is above high set point Input is below low set point

Transducer with Backup

Switches

Input is above high set point;

Dual Switch mode if Trans-

ducer fault is detected

Input is below low set point;

Dual Switch mode if Trans-

ducer fault is detected

Scheduler Date and Time occurs Date and Time occurs

Timed Run Autostart switch pressed Timer expires

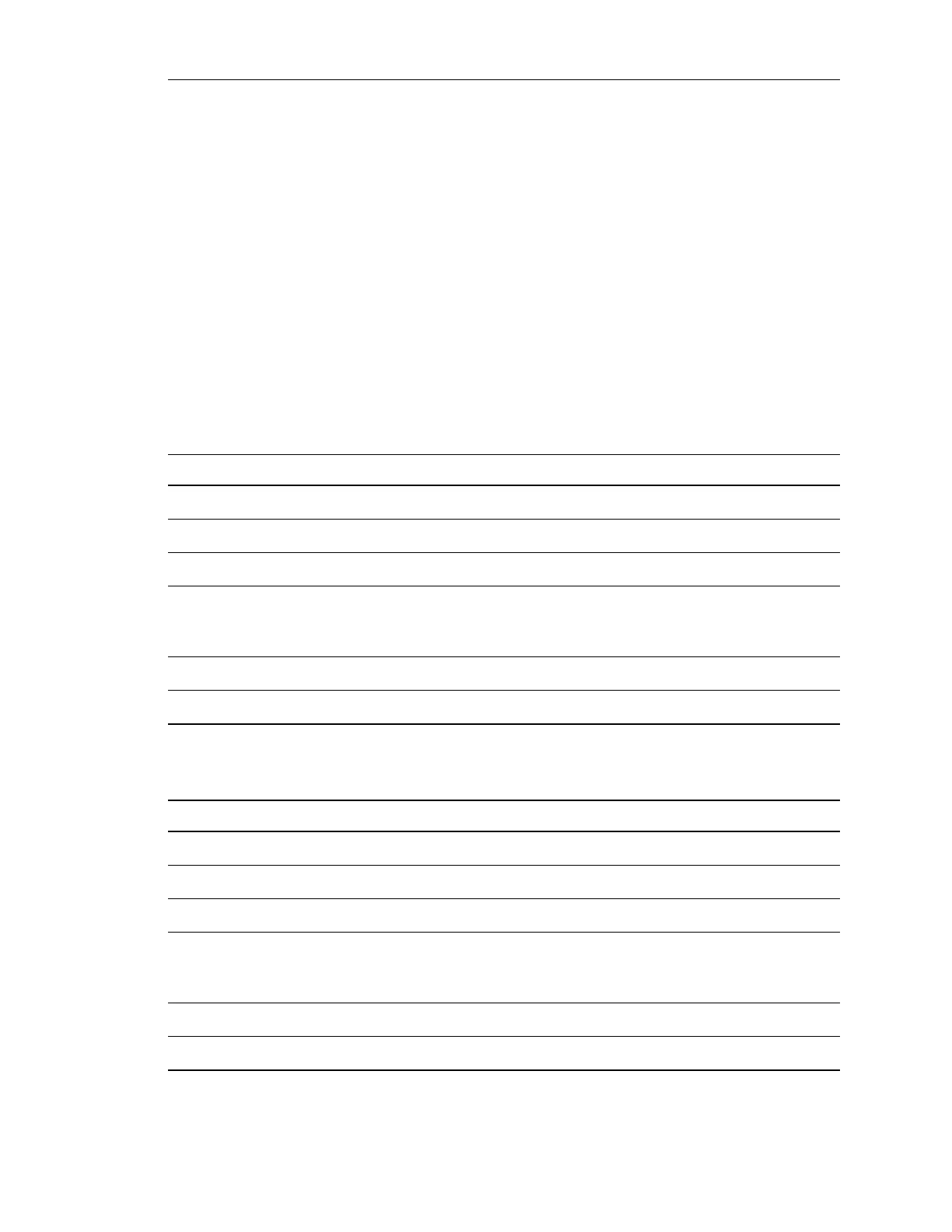

The following table describes the Start/Stop events when behavior operation is set to ”Low to High”

(switches/floats are normally open):

Start/Stop Events Engine Starts When Engine Stops When

Single Switch SW1 is open SW1 is closed

Dual Switch SW1 and SW2 are both open

SW1 and SW2 are both closed

Transducer Input is below low set point Input is above high set point

Transducer with Backup

Switches

Input is below low set point;

Dual Switch mode if Trans-

ducer fault is detected

Input is above high set point;

Dual Switch mode if Trans-

ducer fault is detected

Scheduler Date and Time occurs Date and Time occurs

Timed Run Autostart switch pressed Timer expires

Transducer Fault Detection using Backup Switches

LOFA document No. 463-3002-59 Page 25

Loading...

Loading...