6. Autostart Operation

When configured and equipped with transducer and back up switches, the panel will use the

transducer to determine the primary start and stop events. The switches are used to detected

transducer faults and when a fault is detected, the panel will automatically adjust to use the switches

to detect the start and stop events. The panel will alert to the fault but normal operation will continue

with the exception that the switches will be used instead of the faulty transducer.

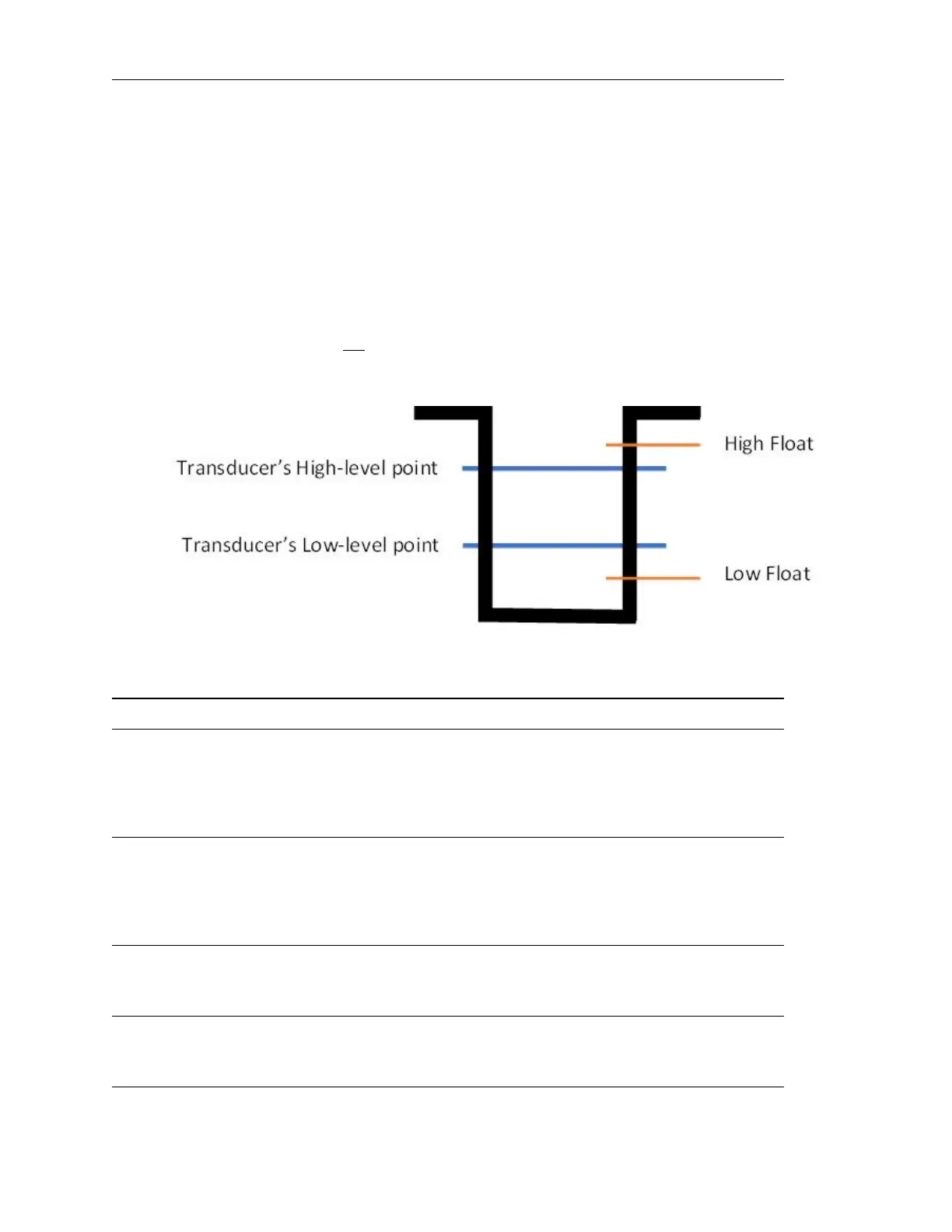

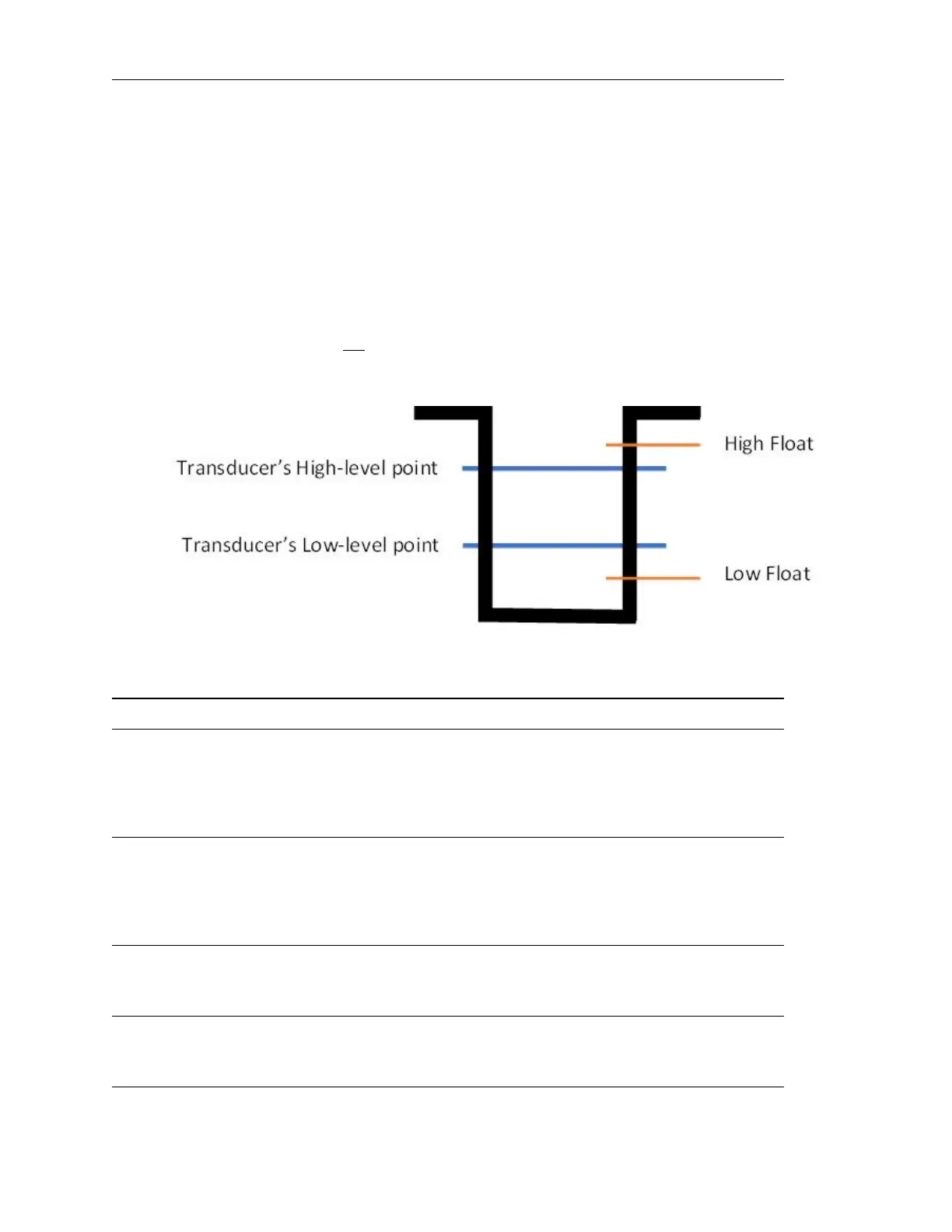

For proper operation and fault detection, the switches must be configured such that the high-switch

open/closes at a level above the transducer’s high-level point and the low-switch open/closes at a

level below the transducer’s low-level point (see fluid pumping example diagram below).

Example: When pumping fluid, the setup should be similar to the following diagram. Typically, floats

function as an Open switch when not floating and Closed when floating.

Faults

Transducer Level Low-Level Switch High-Level Switch Result

Above Low-Level Point Open —

Transducer is within nor-

mal operating range but

value is incorrect (too high)

because low-level float

should be closed

Below High-Level Point — Closed

Transducer is within nor-

mal operating range but

value is incorrect (too low)

because high-level float is

closed

Out of Range (Low) — —

Transducer value is be-

low the normal operating

range (severe)

Out of Range (High) — —

Transducer value is be-

yond the normal operating

range (severe)

6.4.3 Configuring the Transducer

Page 26 LOFA document No. 463-3002-59 Page 26

Loading...

Loading...