G120F/G160F/G200F Part IV Disassembly and maintenance

- 39 -

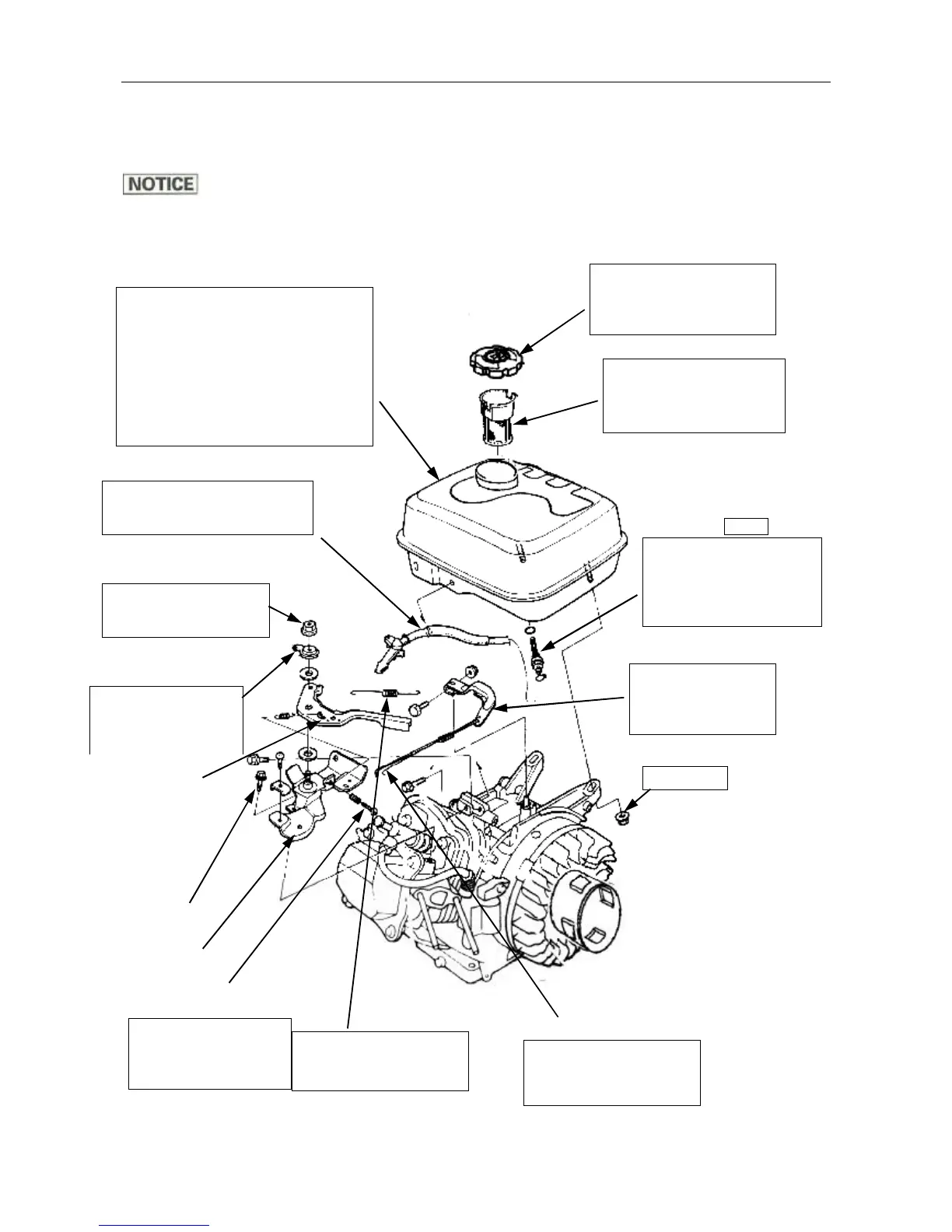

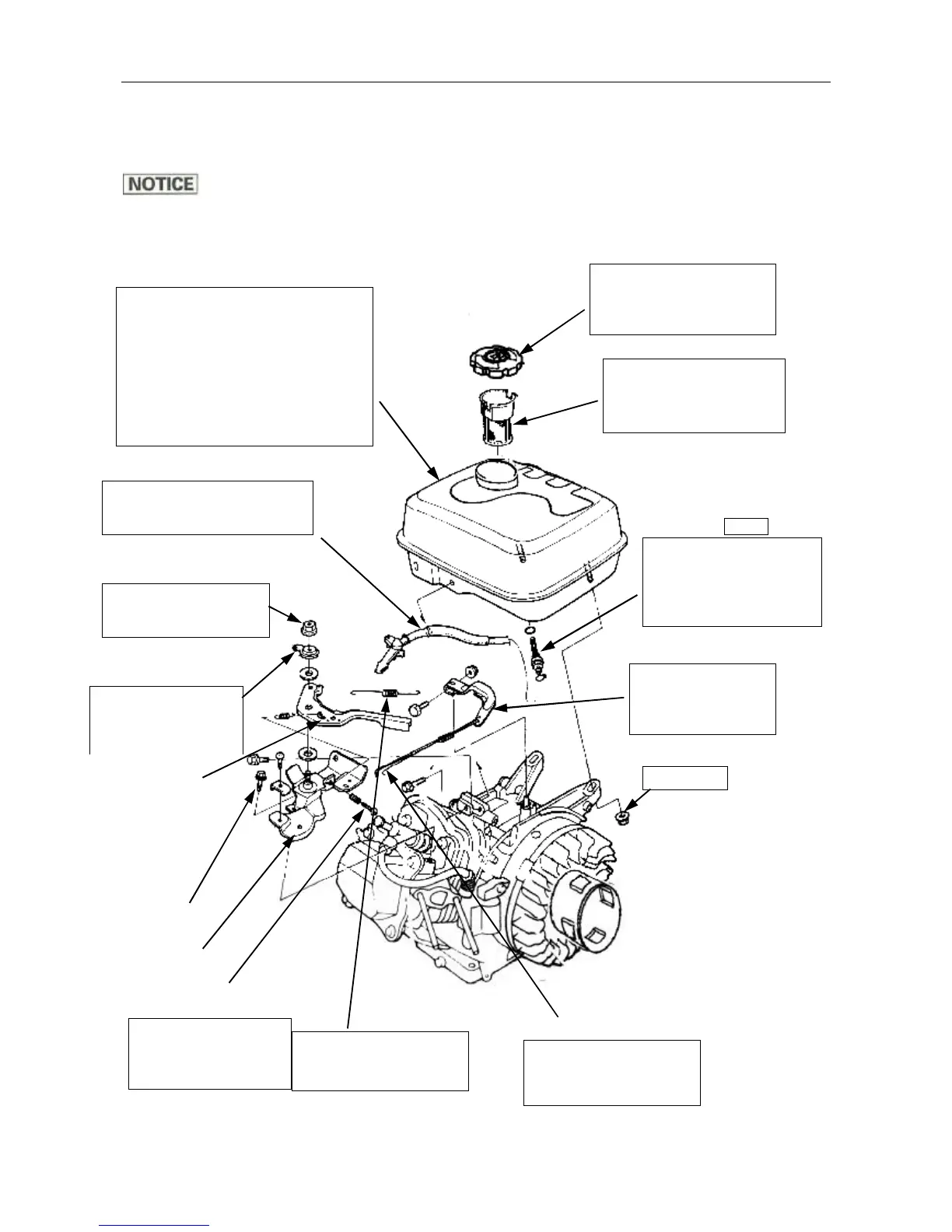

4-4. Fuel tank and speed governing system

Disassembly/reassembly

Gasoline is highly flammable and explosive, keep smoking, spark and flam away,

and drain the fuel tank completely before removal and disassembly.

Fuel tank cap

Reassembly:

Make sure that the air vent

hole is unclogged before

installation.

Reassembly:

Check to be sure the

strainer is clean and

undamaged before

installing.

Fuel tank

Fuel tank capacity: 6 L

Reassembly:

Wash to remove the sediment and dry

thoroughly before installing.

When repairing feul tank joint seams,

adhevise shall be used, if welding has to

be used, it must be performed for the

whole circumference of seam (Never

perform local welding on fuel tank).

Fuel tube

·Replace it every 2 years.

Inspect for cracks or deterioration

before installation.

Fuel filter 2.0N.m

Reassembly:

Check to be sure the

meshes are clean and

undamaged before

installing.

Governor arm

Reassembly:

Adjust the governor

before installation

(P31(3-10))

M6 Lock nut

Reassembly:

Adjust control lever

friction with this lock nut.

Control lever washer

Reassembly:

Align the groove with

the tab on the control

M6X12(2)

Control base

Throttle return spring

Reassembly:

Install with the long end

side hooked to the

governor arm.

Reassembly:

Install with the long end

side toward the control

lever

M5×35cross recessed

pan head screw

Reassembly:

After assembling, start

the engine and adjust to

the rated speed

Loading...

Loading...