G120F/G160F/G200F Part IV Disassembly and maintenance

- 50 -

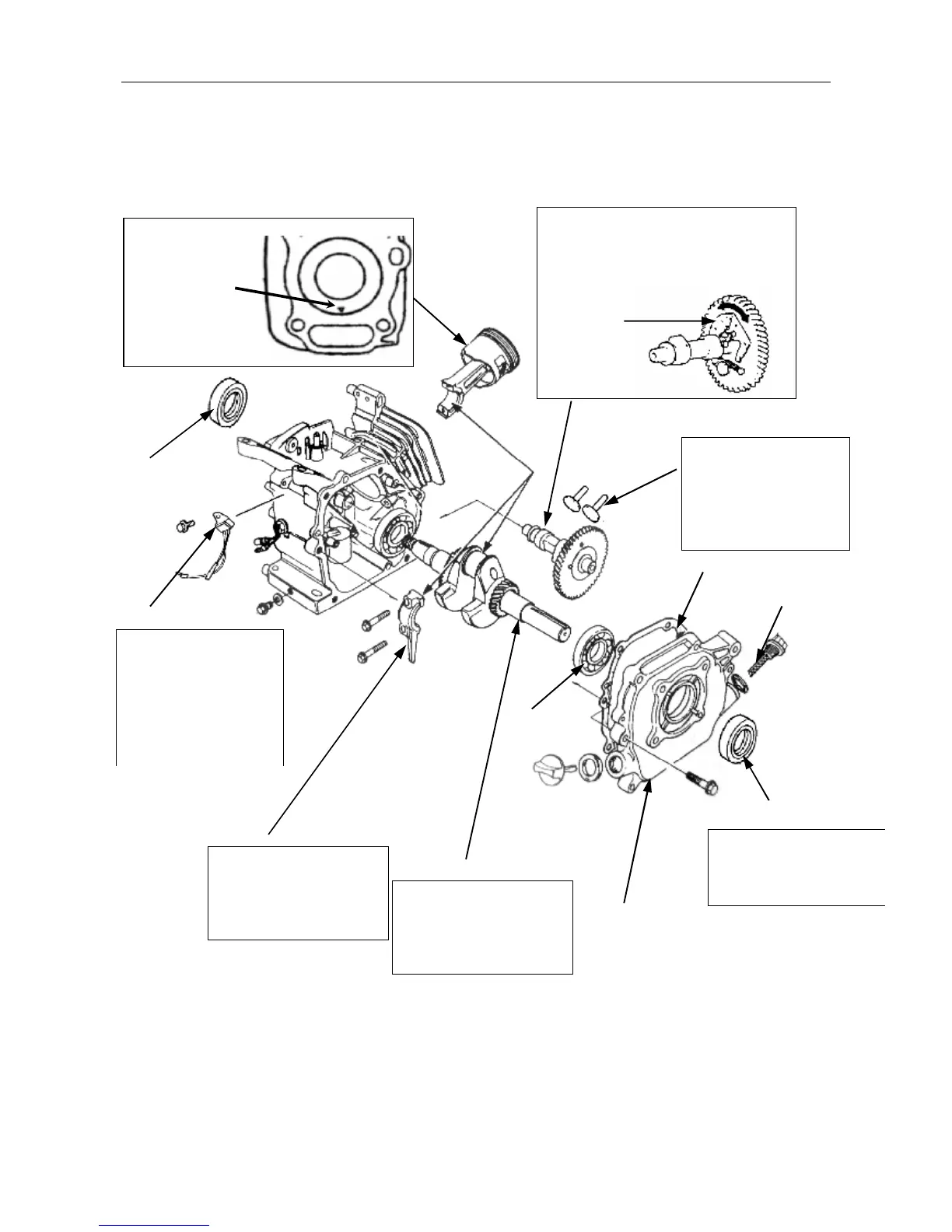

4-7. Crankcase body, piston, connecting rod and crankshaft

1. Diassembly/reassembly

Reassembly:

hole.

Piston

Oil alert unit

Inspection: With the

engine running, when

connecting the yellow

lead and ground wire for a

moment the engine

should stop. If not,

replace oil alert unit.

Camshaft assy

Reassembly:

Check that the decompressor weight

moves smoothly and the spring is not

weak or worn, then align the triangle

marks and install.

Decompressor

Valve lifter

Reassembly:

Install the lifters

immediately before

installing the camshaft;

take care not to let lifters

drop.

Crankshaft

Reassembly:

Push in until the bearing

touches the crankcase. Be

careful not to damage the oil

seal.

Connecting rod cap

Reassembly:

Install with the oil dipper

toward the camshaft and the

ribs on the cap and

connecting rod aligned.

Crankcase cover

Oil dipstick

Oil seal

25×41.25×6

Crankcase cover seal gasket

Oil seal 25×41.25×6

Reassembly:

Take care not to damage

the lip of the oil seal when

inserting the crankshaft

Loading...

Loading...