G120F/G160F/G200F Part IV Disassembly and maintenance

- 48 -

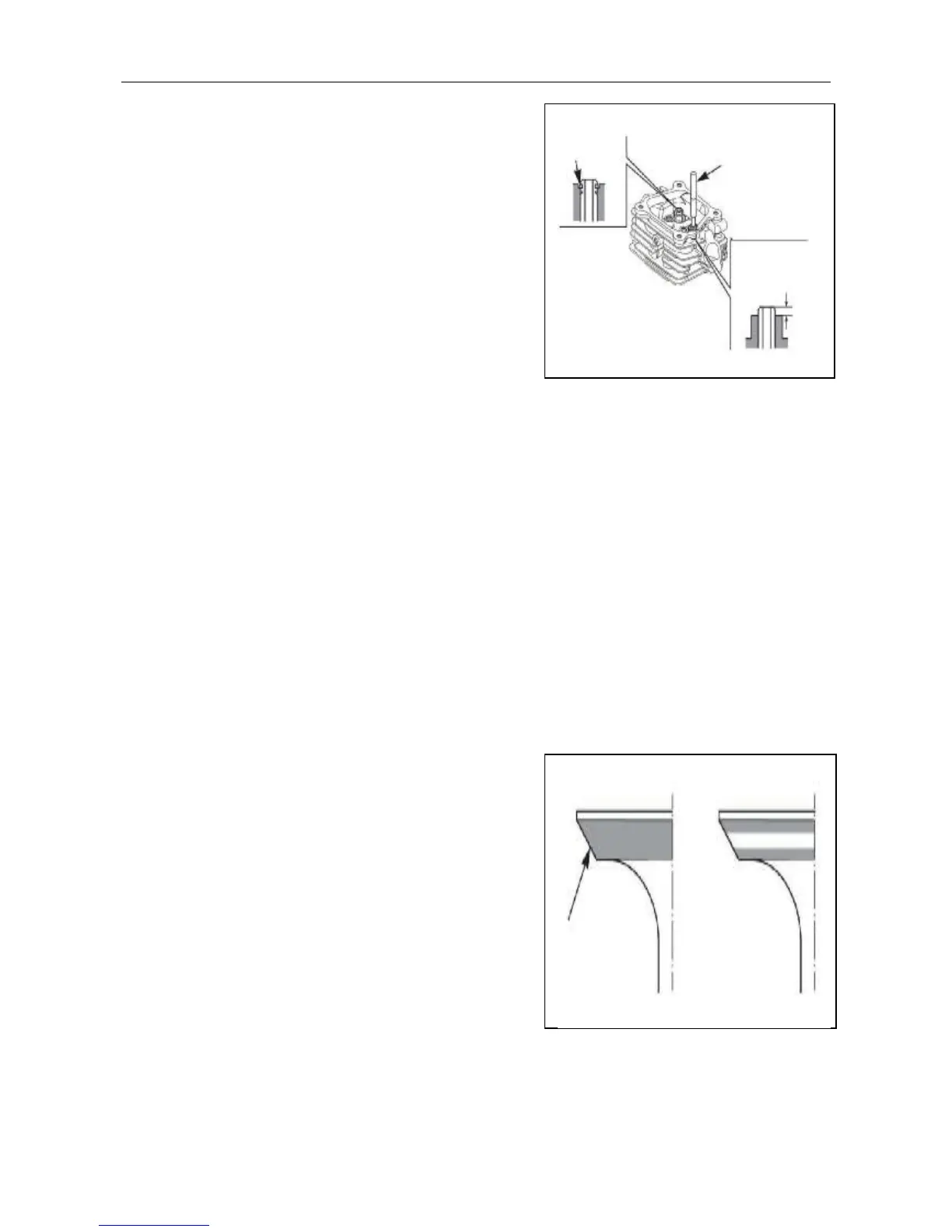

a) Coat the reamer and valve guide with cutting oil.

Rotate the reamer clockwise through the valve guide the

full length of the reamer.

Continue to rotate the reamer clockwise while removing it

from the valve guide.

Tool: valve guide reamer

b) Thoroughly clean the cylinder head to remove any

cutting residue.

c) Check the valve guide bore; it should be straight,

round and centered in the valve guide. Insert the valve

and check operation. If the valve does not operate smoothly, the guide may have been bent

during installation. Replace the valve guide if it is bent or damaged.

d) Check the valve stem-to-guide clearance.

e) Stem –to- guide clearance: Subtract each valve stem OD from the corresponding guide ID to

obtain the stem -to- guide clearance.

f) If the stem-to-guide clearance exceeds the service limit, determine if the new guide with

standard dimensions would bring the clearance within tolerance. If so, replace the guide as

necessary and ream to fit. Recondition the valve seat whenever the valve guide is replaced.

5) Valve seat:

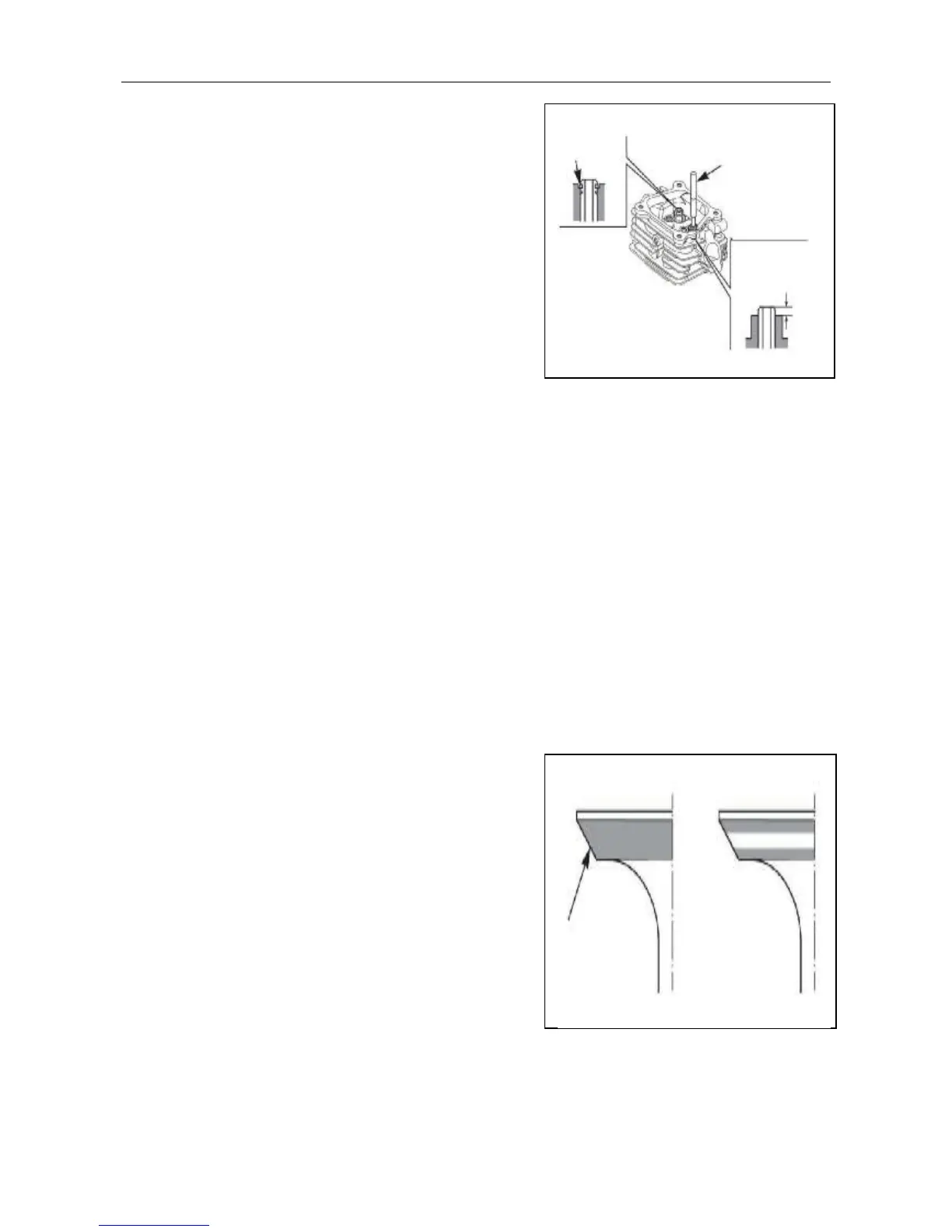

a) Thoroughly clean the combustion chambers and

valve seats to remove carbon deposits. Apply a light

coat of red lead power or erasable color on the valve

faces.

b) Insert the valve, and then lift them and snap them

close against their seats several times. Be sure the

valve does not rotate on the seat. The transferred

marking compound will show any area of the seat that

is not concentric.

Guide

clip

Valve

guide

driver

Loading...

Loading...