31

EN

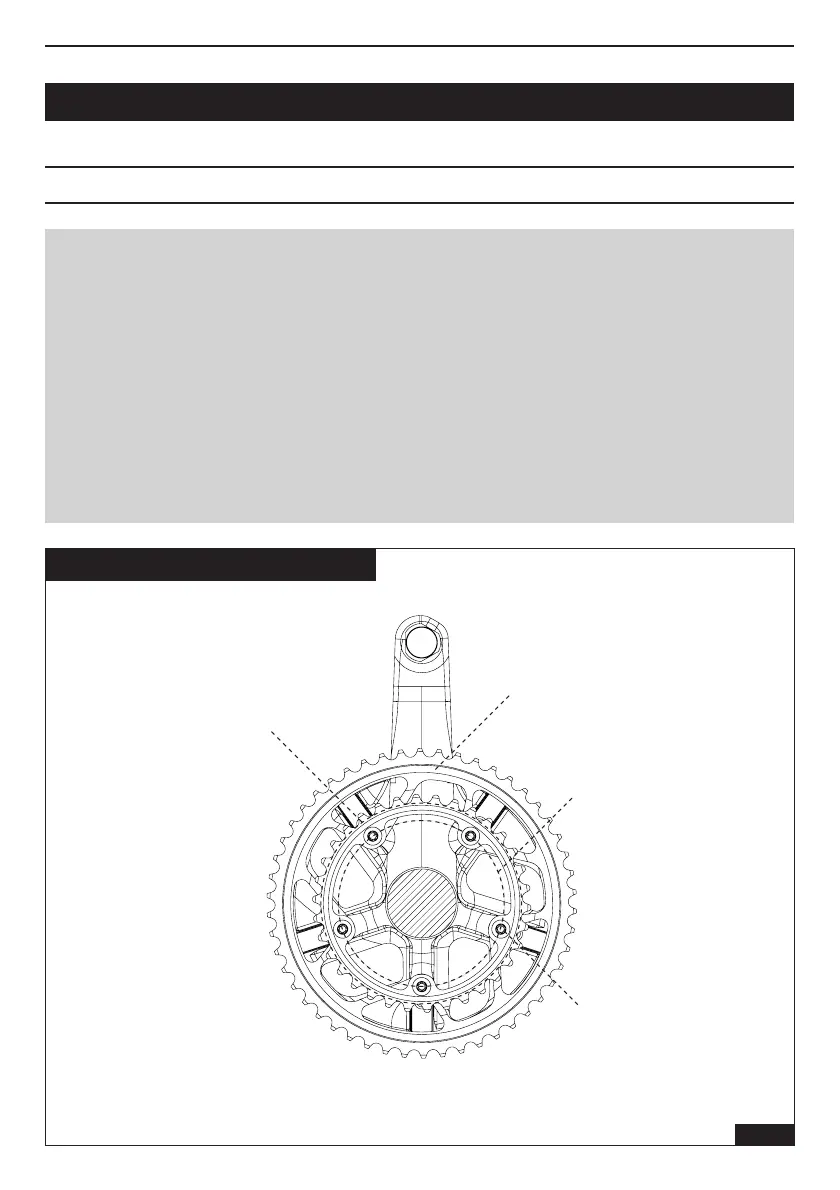

Orientation of the chainring

through alignment of the

chain’s anti-skip cone with

thecrank.

Holes in the star distributed

over a circle with a diameter

of 130mm (the largest) to t

thedoublechainrings.

Holes in the star distributed

overa circle with a diameter

of110mm(thesmallest)tot

thecompactchainrings.

Tightening of the chain-

ring mounting screw to

8Nm.

CHECKING THE FIT OF THE CHAINRINGS

Fig 6

Checking how the chainrings have been tted:

Whenyoutthechainrings,check:

- Theorientationofthechainringssothatthegearschangecorrectly.

- Thepositionofthechain’santi-skipconeontheexteriorchainringinordertoavoidthechain

becomingstuckbetweenthechainringandthecrank.Thechain’santi-skipconemustbebehindthe

crank.

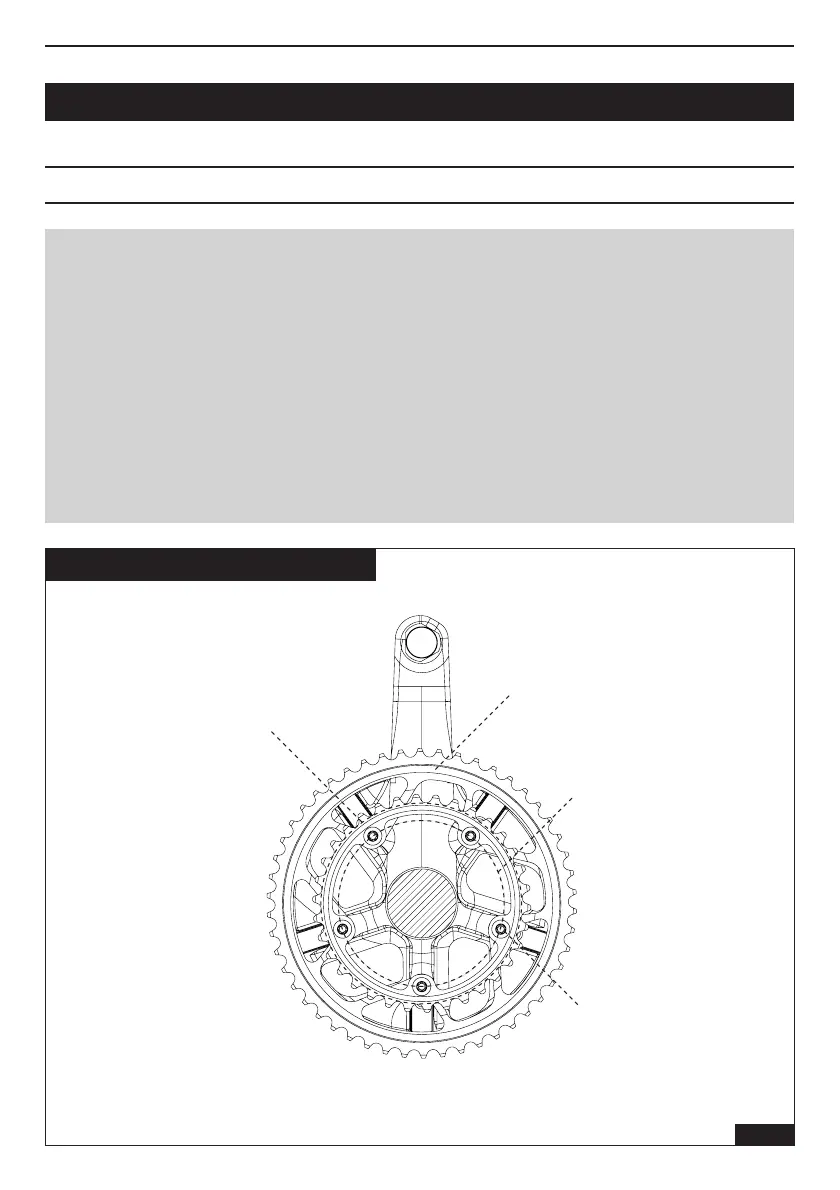

Attention :

LOOKrecommendstheuseofitsspecicchainringsfortheZEDcranksetforthefollowingreasons:

- ThespecicshapeoftheteethoneachLOOKchainring,whichfacilitatesthegearchanges,was

developedtorespondtobeingttedtothedoubleand/orcompactZEDstar.

- ThestrengthandrigidityoftheLOOKchainringshavebeenoptimisedparticularlythankstoa

largersupportsurfacewhereeachbranchisattached.

FITTING THE CHAINRINGS ON TO THE CRANKSET (cont.)

Loading...

Loading...