Before start-up

- 9 -

11.18 909.1550.1-08

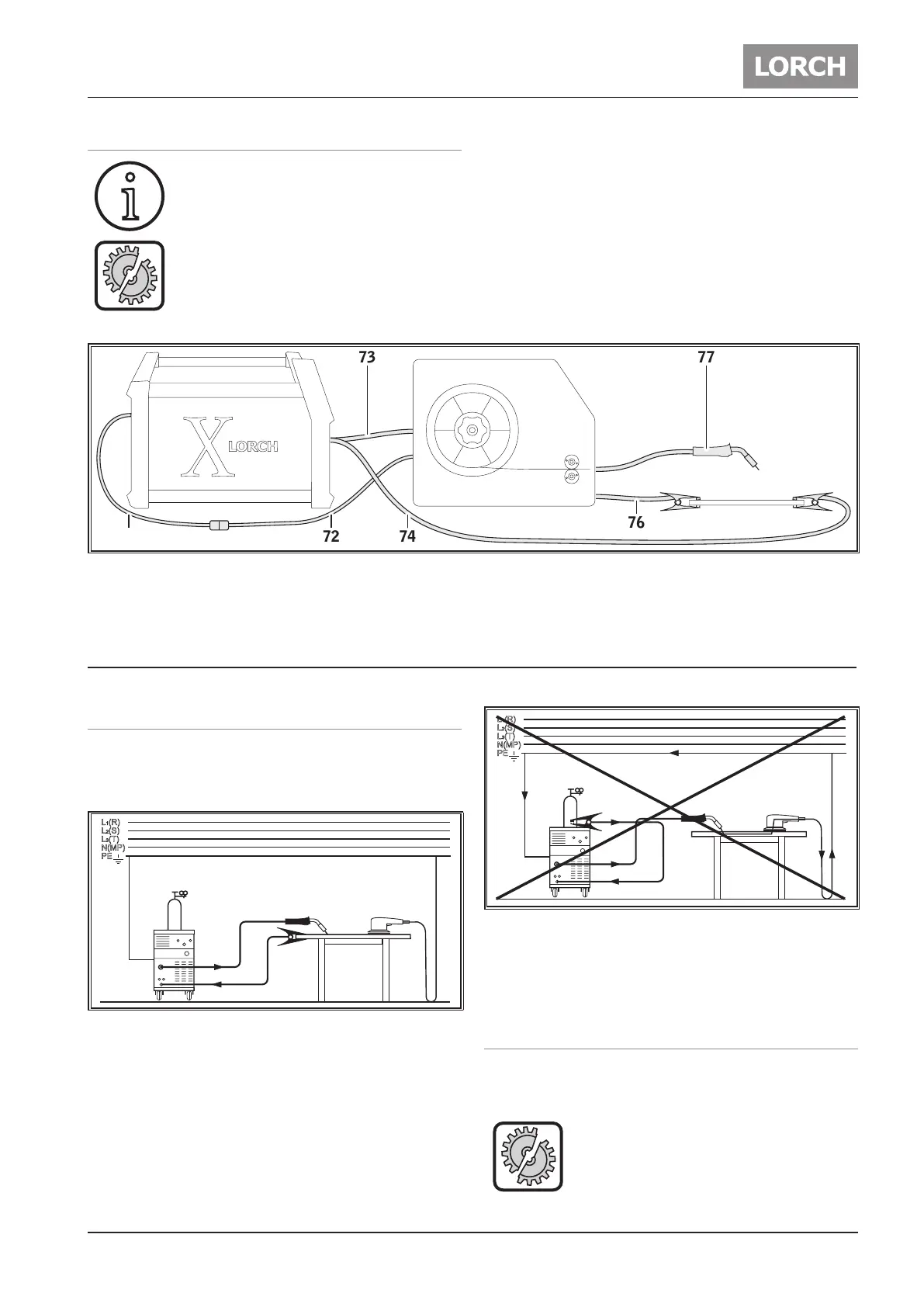

11.6 Connecting the ground cable

Connect the ground cable to the free minus or plus 8

socket and secure the cable by rotating it clockwise.

Fastening the ground clamp

Abb. 5: Attaching the ground clamp - Correct!

Fasten the grounding clamp in the immediate vicinity

of the welding area, so that the welding current can-

not seek its own return path across machine parts,

ball bearings or electric circuitry.

Connect the ground clamp rmly to the welding bench

or the workpiece.

Abb. 6: Attaching the ground clamp - Wrong!

Do not place the ground clamp on the welding ma-

chine or the gas cylinder; otherwise the welding cur-

rent will be carried via the protective conductors and

it will destroy these.

11.7 Connecting the power supply

The machine is suitable for operation on the mains sup-

ply or on a current generator.

Plug the mains plug into the appropriate socket.

The mains voltage and tolerance as well

as the fuse protection must correspond to

the technical specications (see Technical

Specications).

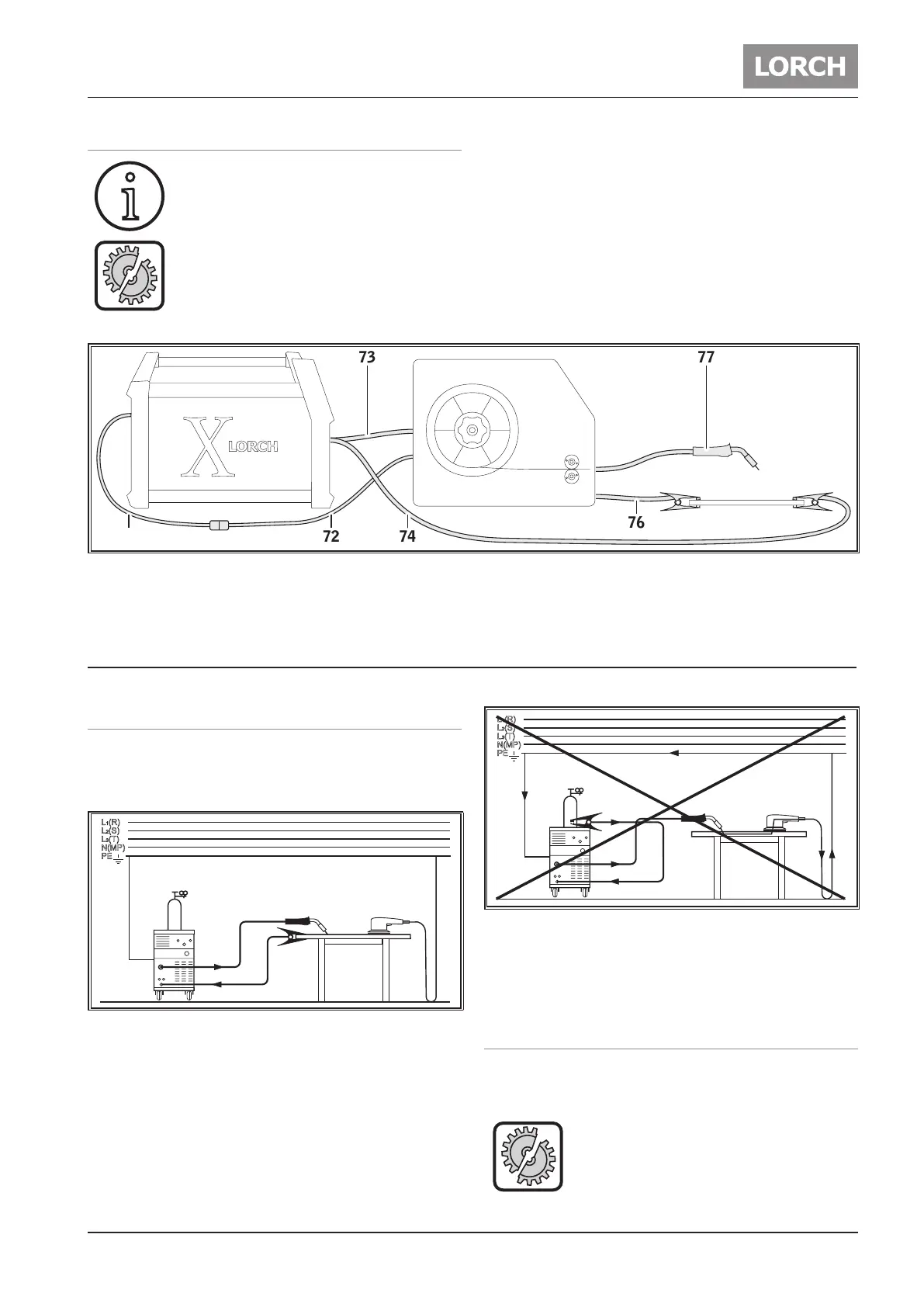

11.5 MIG welding process

A wire feed case (optional) is required for

MIG welding.

The operations required may differ depend-

ing on the version and the conguration of

the wire feed case!

Please observe the wire feed case operat-

ing manual!

Connect the welding cable of the wire feed case to

the connection socket minus or plus 8 of the power

source (X 350).

Connect the control cable of the wire feed case (with

adapter if necessary) to the remote control connec-

tion socket (7) of the power source (X 350). (if tted)

Equipping the wire feed case. (See wire feed case

operating instructions)

73

7270

74

76

77

75

71

Abb. 7: MIG welding connection diagram

70 Control cable adapter (optional) 73 Welding cable 76 Component guide

71 Power source (X 350) 74 Component guide 77 MIG/MAG torch

72 Control cable 75 Wire feed case

Loading...

Loading...