Preparing to Install the Pump5

Warnings for Handling Helical Rotor Pumps5.1

WARNING (helical rotor models) DO

NOT APPLY MACHINE GREASE TO THE

PUMP. Ordinary machine grease will

damage the stator (NBR rubber) and

void the warranty. Helical rotor pumps are

lubricated at the factory with a clear, non-toxic

grease. Its only purpose is temporary, to allow the

pump to be run dry for a short time to test the

direction of rotation. There is no normal reason to

reapply lubricant but if you do, use VASELINE

(petroleum jelly, white petrolatum) or non-toxic

silicone grease approved for water valves and

seals.

WARNING FOR SIPHON APPLICATIONS

If a pump system has a vertical lift

LESS THAN 33 ft (10 m) up from the

surface of the water source, and then

the water flows downhill to a lower point, a siphon

effect may cause suction on the pump. This will

cause an upward thrust on the motor shaft,

resulting in damage to the motor. Prevent this by

installing an air vent or a vacuum breaker at the

high point on the pipe.

CAUTION (helical rotor models)

BEFORE INSTALLATION, KEEP THE

PUMP OUT OF THE SUN. If the pump

gets hot, the rubber stator will

expand and may lock the rotor. No damage will

result from this, but you may be unable to test the

direction of rotation. If the pump gets hot, allow it

to cool in water for 20 minutes before testing.

Pumps should not be stored in water

for a period longer then three month.

Too long storage time might seize the

pump up. Pumps will not be

damaged, but might have to be pulled to free them

again. Therefore it is strongly advised that every

two to three months the pumps should run for a

few minutes.

Assembling the Rotor on the Motor Shaft5.2

What you need:

glue Loctite 222

acetone or alcohol, 50 ml

wrenches 13 mm, 22 mm,

1m steel pipe to extend 22mm wrench.

a piece of cloth or a towel

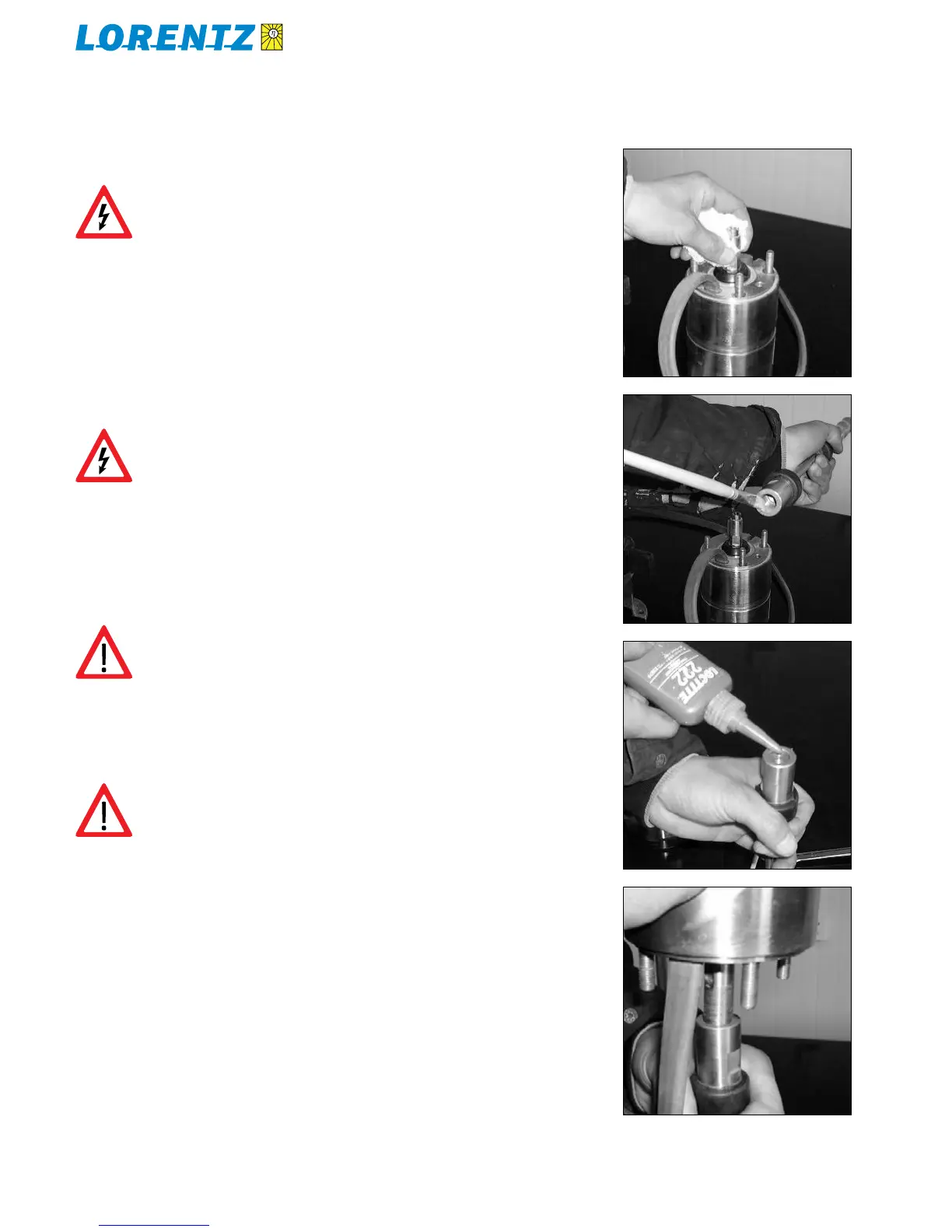

Unthread 8 M8 nuts to take the pump housing out(1)

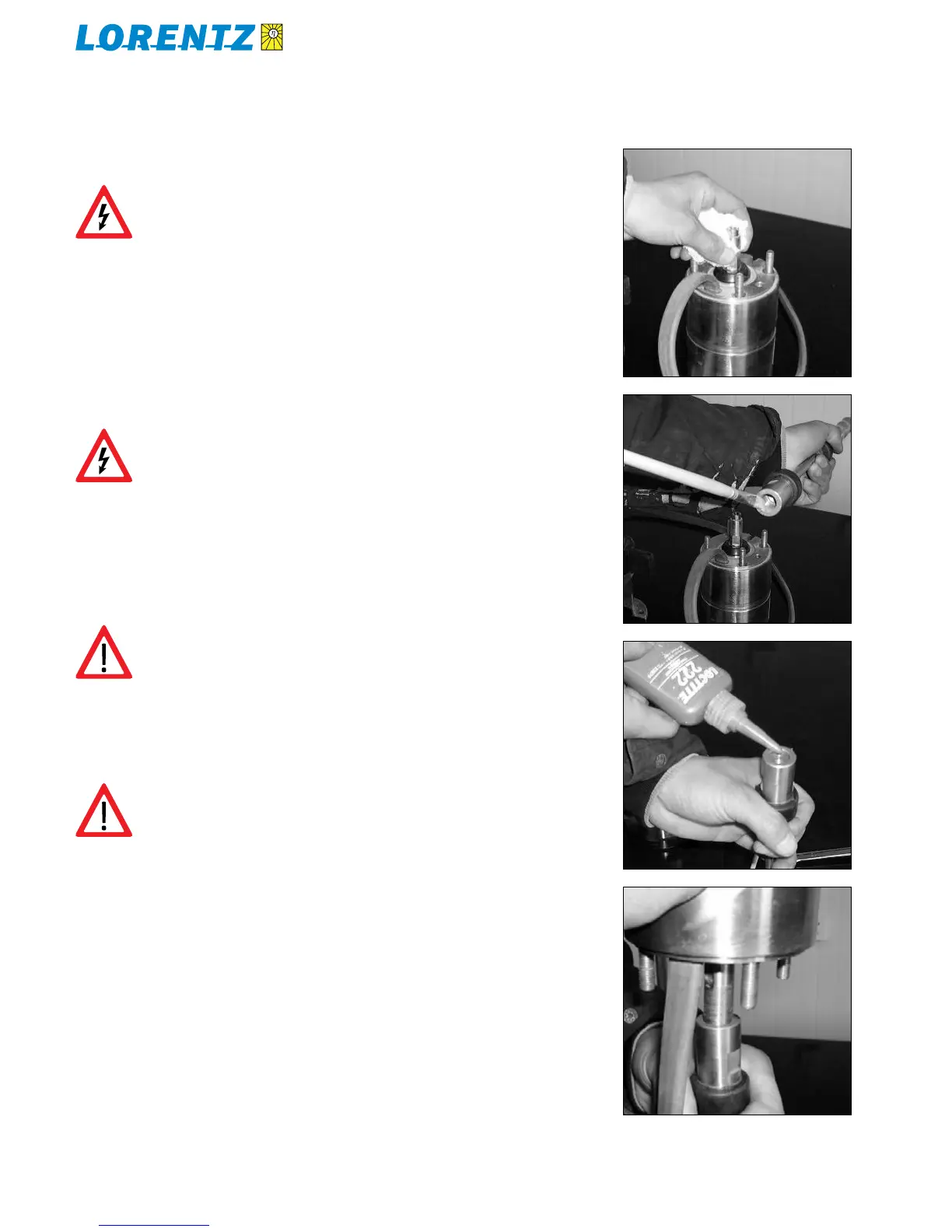

Settle motor horizontally, use wrench 13 mm to fix mo-(2)

tor shaft, 22 mm wrench with 1 m extension pipe fixed

on pump rotor shaft. Push down the extension pipe

anticlockwise from motor flange view, with ~50 Nm

torque, rotor shaft will be unthreaded from motor

shaft. NO TORCH

Clean motor screw shaft and inner thread of rotor (3)

M16 with a cloth dipped in acetone or alcohol.

Drop approx. 1 ml Loctite 222 glue into thread (4)

chamber M16 of rotor, then thread rotor shaft on to

motor shaft.

Take a 13 mm wrench to fix motor shaft, 22 mm (5)

wrench to fix rotor shaft, fasten them by hands as

hard you can. 50 Nm are needed to fix pump rotor

with motor shaft. Clean the glue that got squeezed

out.

Clean motor flange and four bolts, make pump hous-(6)

ing assembly and settle it on motor flange, drip a drop

of Loctite 222 glue on each bolt. One 8 mm spring

washer and two pieces of M8 nuts are used to fix

pump end on each bolt. 12 Nm are needed to fix nuts.

Clean the glue that got squeezed out.

An hour later the glue will be have dried and be suf-(7)

ficiently adhesive. Then the pump can be used or put

down to well.

Assembling the Rotor on the Motor Figure 15:

Shaft

Loading...

Loading...