Installation in a Surface Water Source5.5

This refers to a surface well, spring, pond, lake,

river or tank.

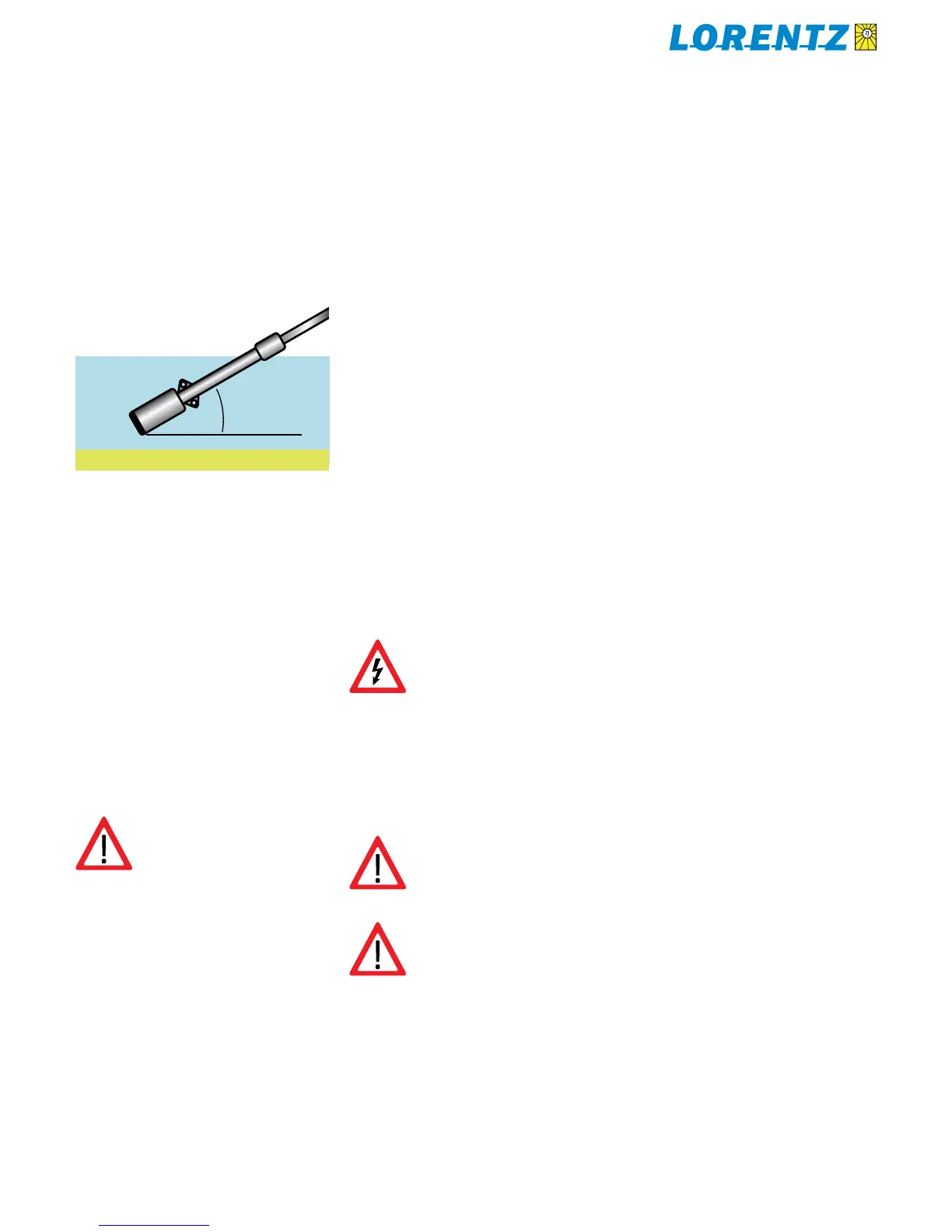

Positioning the pump The pump may be placed in an

inclined position with a min. angle of 30° if desired.

water starting at the SURFACE of the water in the source.

Increasing the submergence of the pump (placing it lower

in the source) will NOT cause it to work harder or to pump

less water. Avoid placing the pump close to the bottom

where it will pick up sediment.

Filtration at the pump intake PS pumps will tolerate

small amounts of sand, but you may need to filter out

larger debris that is normally found in a pond or stream.

You can construct a simple coarse screen to protect the

pump and to reduce the nuisance of debris in your water

system. One method is to wrap the pump with about 6-8

layers of loosely-woven fabric or screen, of a material that

will not decay or rust. Some suggestions are fiberglass win-

dow screen, agricultural shade cloth, or weed-barrier fabric

(available from nursery and landscaping suppliers). Bind

the fabric or screen with all-stainless hose clamps, rubber,

or polypropylene rope. Do not use nylon; it softens with

submersion in water. An improved method is to construct

a sealed pump enclosure from 4-6 in plastic pipe, with

many holes or slots to let water in. Then, wrap the screen

around that enclosure. This will distribute the flow through

a much larger area of screen. After cutting holes or slots in

the plastic pipe, wipe the inside carefully to remove plastic

shavings and dust.

WARNING for SIPHON APPLICATIONS

If a pump system has a vertical lift of

less than 33 ft (10 m) up from the

surface of the water source, and then

the water flows downhill to a lower point, a siphon

effect may cause suction at the pump outlet. This

will cause an upward thrust on the motor shaft,

resulting in damage to the motor. Prevent this by

installing an air vent or a vacuum breaker at the

high point on the pipe.

CAUTION The pump must be fully

submerged. A helical rotor pump may

overheat and stop (temporarily) if

the pump end is not fully submerged.

CAUTION High water temperature

can cause failure to start. Low

temperature can reduce lift and flow

capacity. This can occur in surface

water during weather extremes, due to temporary

expansion or contraction of the rubber stator. The

product specifications say: Optimum water temp. is

46°F to 72°F (8°C to 22°C). Other ranges are

available by special order. These performance

problems are temporary and will NOT damage the

pump. If you are uncertain about using the pump

you received, contact your supplier before you

install it.

Deep Well Setting — How Deep?5.6

PS pumps may be submersed as deep as necessary to

ensure reliable water supply. The lift load on the pump

is determined by the vertical head of water starting at

the SURFACE of the water in the source. Increasing the

submergence of the pump (placing it lower in the well) will

NOT cause it to work harder or to pump less water, nor will

it increase the stress or wear on the pump.

There are reasons NOT to set the pump near the bottom of

the well, if it is not necessary:

A deep setting will increase the size requirements, 1.

costs and weight of pipe and cable.

A deep setting may increase the chance of sand or 2.

sediment being drawn into the pump.

To make an informed decision, it is helpful to have accurate

data for your water source. In most places, drillers are

required to report the details and the performance of wells

that they drill. If you do not have the driller’s well record,

you may be able to obtain a copy from your regional gov-

ernment office that oversees ground water resources and

issues drilling permits. In USA, it is a state office, typically

called Department of Natural Resources or State Engineer’s

Office. However, the data may be missing or inaccurate, and

conditions can change over the years. In critical cases, it is

wise to have the well re-tested by a water well contractor.

Models 03, 03H, 04 and 04H have a small “vent hole” near

the top of the pump (photo). If the hole is not submersed,

it will suck air and prevent the pump from performing fully.

The purpose of this hole is to allow water to fill an internal

gap, to conduct heat away from the rubber stator.

River or stream To reduce the intake of sediment, do not

place the intake very close to the bottom of the stream or

pond. Secure the pump from logs and debris that may float

downstream. Use stainless steel wire rope or chain instead

of plastic safety rope (plastic rope will weaken in sunlight).

Consider digging a shallow well near the stream. This will

allow filtration of the water through the earth, and will

protect the pump from floating debris or human tampering.

CAUTION The low-water probe must

be positioned vertically, within 10°.

Normally, it is to be installed on the

pipe above the pump outlet, as

shown in section 5.9. This will only work if the

pump is installed vertically. If the pump is will NOT

be vertical, find an alternative way to mount or

suspend the probe, so that it is higher than the

pump, and in a vertical position.

Is a flow sleeve required? NO, not within the normal

temperature range. The PS pumps high-efficiency motor

generates very little heat. A conventional submersible

pump requires a flow sleeve to assist motor cooling when

installed in open water (not confined by a narrow casing).

It is a piece of 4-6 in pipe that surrounds the pump to

increase flow around the motor.

Depth of submersion PS pumps may be submersed as

deep as necessary to ensure reliable water supply. The lift

load on the pump is determined by the vertical head of

min. 30°

Minimum angle when positioning the Figure 18:

pump in an inclined position

Loading...

Loading...