Helical Rotor Models12.2

Positive displacement action The helical rotor pump

differs from centrifugal pumps in that it maintains high

efficiency and lift capacity even at low rotational speeds

and low flow rates. This allows the pump to work with

a small, inexpensive solar array, and to function in low

sunlight conditions.

The helical rotor pump has only one moving part. It

produces a smooth flow and requires no valves to function.

It is far more reliable than diaphragm and piston-type solar

pumps.

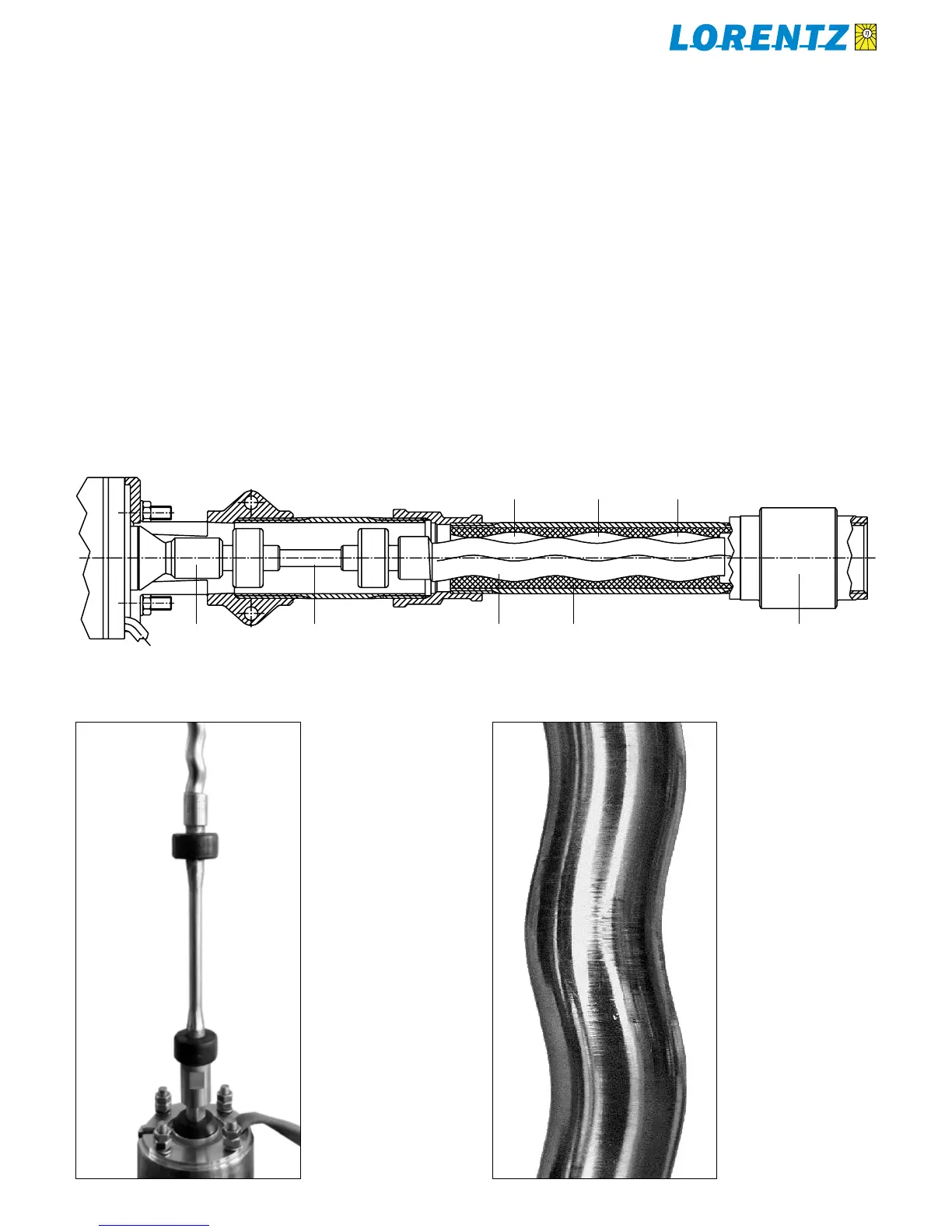

Helical Rotor Pump HeadFigure 29:

coupling flex shaft helical rotor rubber stator non-return valve

Sealed cavities trap water and progress toward the outlet

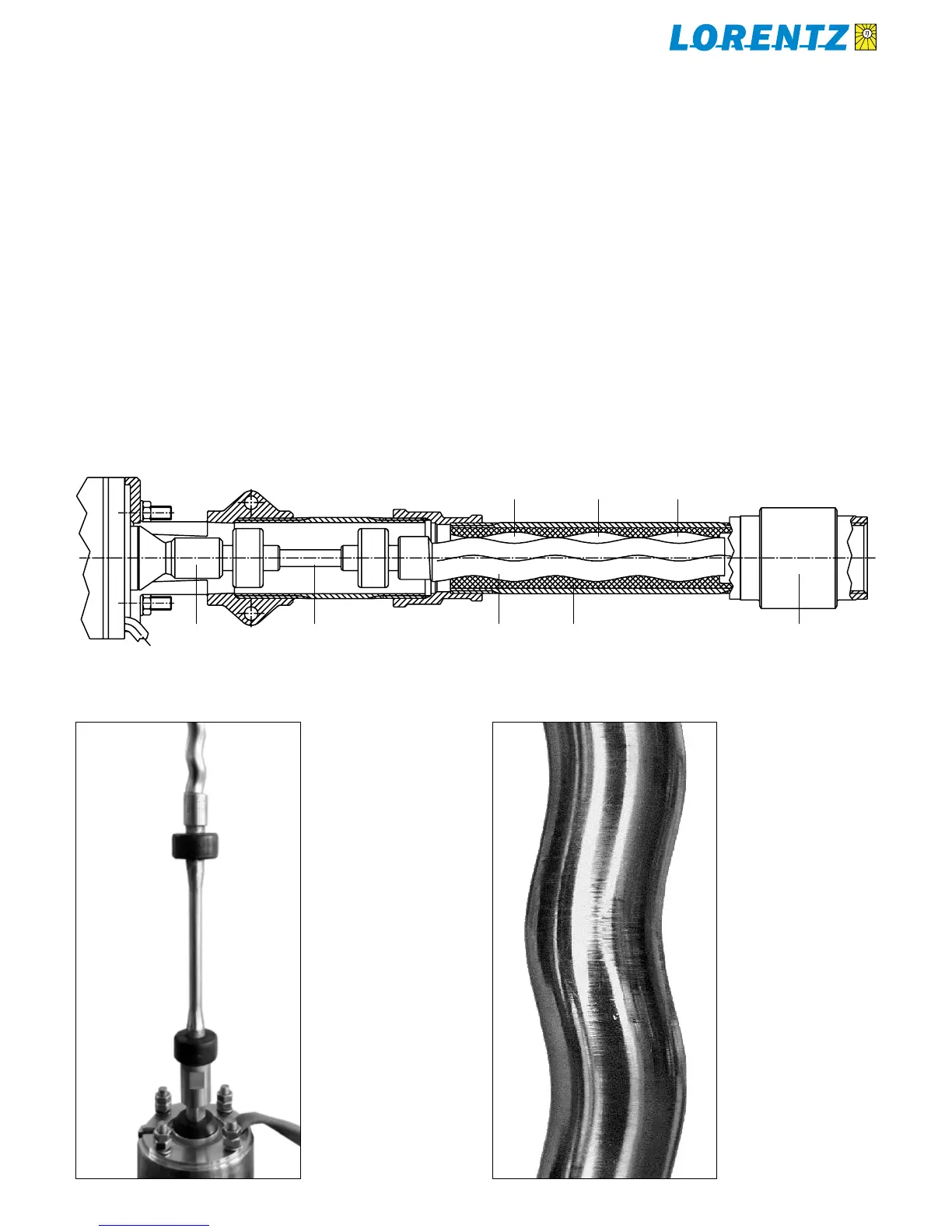

Close-up of Figure 30:

helical rotor

Close-up of the same rotor.

This is a test specimen that

pumped extremely sandy wa-

ter for 500 hours in the test

lab. The surface is almost like

new, and the pump performs

to full specifications.

Motor with Figure 31:

helical rotor attached,

stator housing removed

Self-cleaning action The rotor sweeps the full surface

of the rubber stator with every turn. It is impossible for de-

posits to accumulate. Solid particles tend to roll away from

the contact area, making the pump extremely resistant to

abrasion. Particles that are trapped against the rubber are

tolerated by the flexibility of rubber.

Some history Helical rotor pumps have been used in

the oil industry for over 60 years. They are used to pump

concrete! They have been used for solar pumping since the

1980s, but were very expensive until the LORENTZ helical

rotor pump was introduced.

Loading...

Loading...