In-well Assembly and Installation6

Rubber Spacers6.1

This applies ONLY to models HR-07, 10, 14 and 20 (HR-07,

14 and 20 pump ends).

Helical rotor pumps vibrate due to the eccentric rotation of

the helical rotor. This is normal. Rubber spacers reduce the

vibration that may be transferred to the well casing. Models

-03 and -04 vibrate very slightly so they are not supplied

with rubber spacers.

Pump heads with and without rubber Table 2:

spacers

Pump head without

rubber spacer

with

rubber spacer

HR-03

HR-03H

HR-04

HR-04H

HR-07

HR-07H

HR-10

HR-14

HR-14H

HR-20

HR-23

Clearance for drilled well casings Rubber spacers fit a

6 in (150 mm) inside-diameter or larger well casing.

Cut the rubber spacer legs to fit smaller casing If

you are installing the pump in a well casing smaller than

6 in (150 mm), cut the spacer legs. Grooves indicate where

to cut for a 4 in (100 mm) casing. Use a fine-tooth saw to

cut the rubber.

Pump head with Figure 21:

and without rubber spacers

Machine Installation6.2

If you are professionally equipped to install conventional

AC submersible pumps, you can use the same equipment

and methods for our pumps. PS pumps have no special

pipe requirements. You can use any suitable rigid or flexible

pipe. The only exception is to consider reducing the pipe

size in cases of high sand concentration (to increase flow

velocity). See sections 6.3, Drop Pipe, and 13.3, Water Pipe

Sizing Chart

Installing the Pump Under a Windmill or Hand 5.9

Pump Cylinder

PS pumps can be combined with a classic water-pumping

windmill or hand pump, to utilize both energy sources

automatically. The following system is often used with a

conventional AC pump, so a generator can be used for

backup. The AC pump is placed immediately below the

cylinder, and connected to the cylinder’s threaded intake.

When power is applied to the AC pump, it pushes water

up through the cylinder, pushing its valves open. When the

windmill draws water, it sucks it up through the AC pump

with little resistance. (The centrifugal pump end of the

standard AC pump allows water to flow through it when it

is stopped.) When both pumps operate, each one is relieved

of its load, more or less.

This system can be employed with PS pumps. A centrifugal

model (one with a “C” in the model number) will allow

water to flow freely through it and does NOT require any

special precautions. For helical rotor models, the following

warning applies.

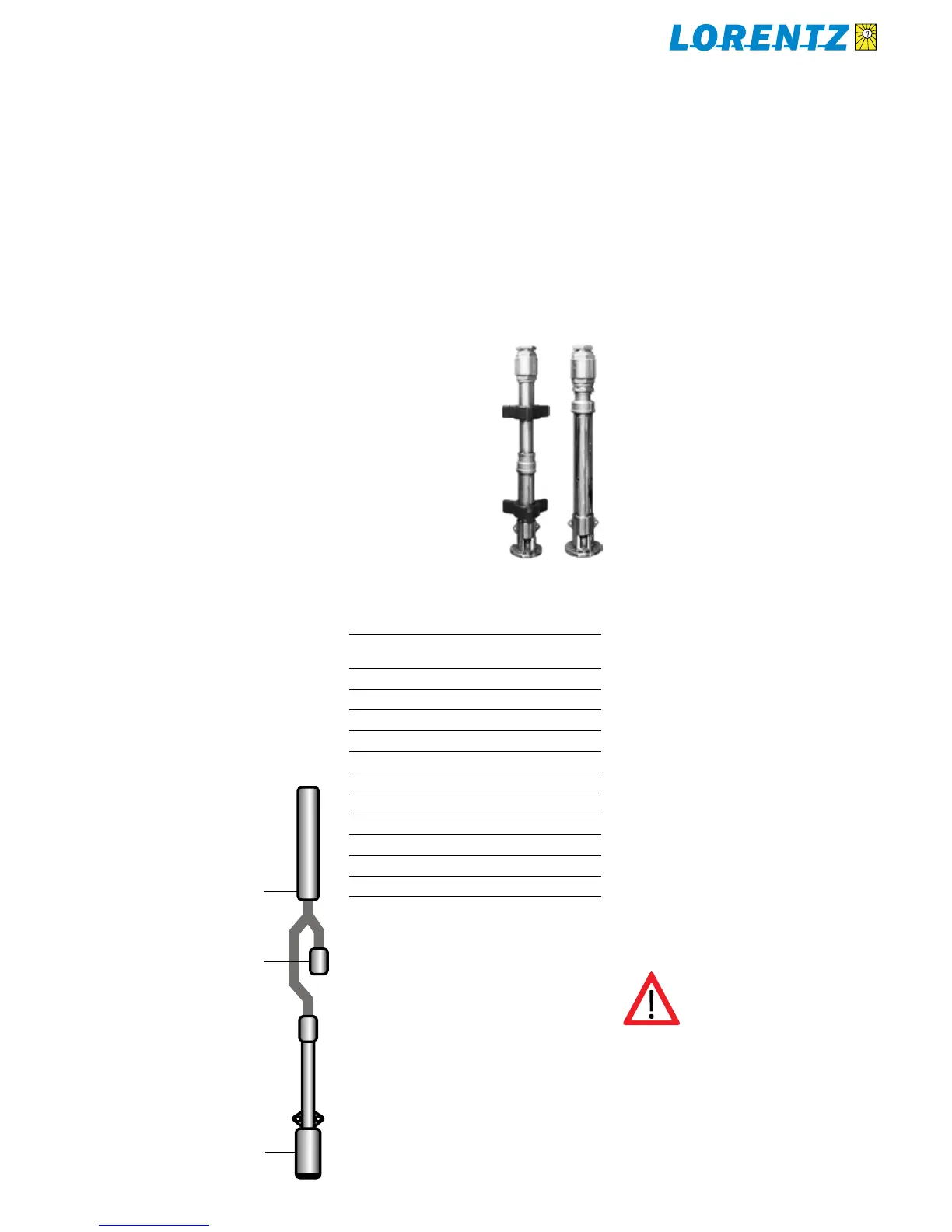

To use a helical rotor pump under a cylinder, you must build

a bypass assembly with a T fitting and a foot valve (a check

valve with intake screen). When the cylinder’s flow exceeds

that of the solar pump, water is sucked in through the foot

valve. When the solar pump’s flow exceeds that of the

cylinder, the foot valve closes and allows the solar pump to

work normally and push up through the cylinder.

To make this system for a casing 6 in (150 mm) or smaller,

an offset using 45° elbows must be carefully constructed,

as illustrated. Copper fittings must be used for the bypass

assembly due to the limited space in the well casing. Do

not use any iron fittings in this assembly.

Bypass foot valve assembly Figure 20:

with offset elbows to fit a drilled well

casing

windmill or hand pump cylinder

foot valve

pump

CAUTION The threads in the check

valve require an adhesive sealant.

They are not tapered pipe thread.

Normally, there is no reason to

remove the check valve. If you do remove it, use a

hardening adhesive sealant or epoxy glue when

you replace it. See CAUTION in section 9.1

Loading...

Loading...