Page 12 of 35

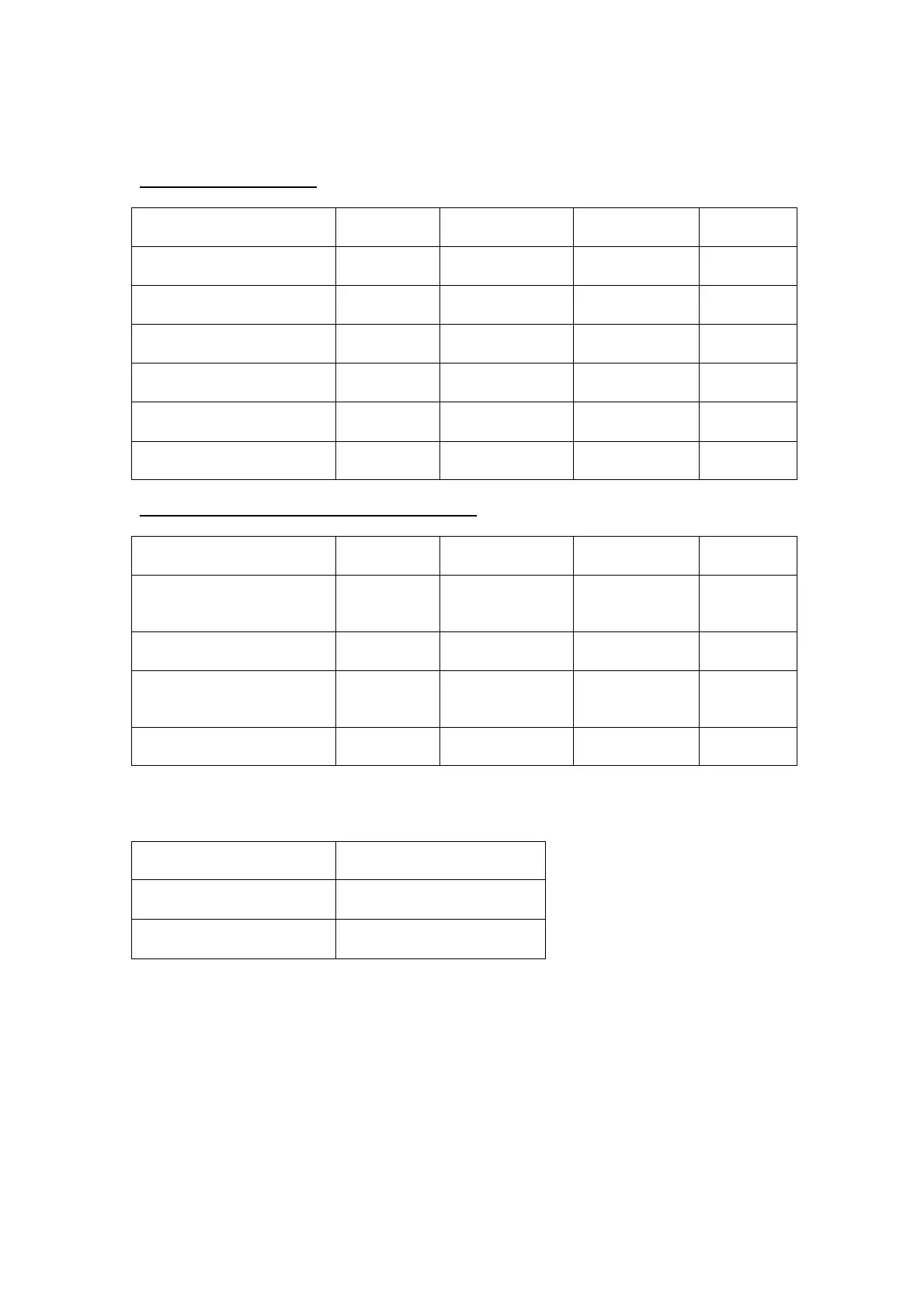

2.5 Typical cycles

The table below shows details of some typical operating cycles, showing set values for

different types of load.

Multi Purpose Machine

OPERATING CYCLE

NAME

CYCLE OR

LOAD TYPE

STERILIZING

TEMPERATURE

STERILIZING

TIME

COOLING

RATE

MEDIA Fluid 121

C 15 minutes 40 minutes

to 80

o

C

FLUID DISCARD Fluid 134

C 5 minutes 40 minutes

to 80

o

C

PLASTIC DISCARD Plastic

Discard

134

C 5 minutes 30 minutes

to 80

o

C

EMPTY GLASSWARE Empty

Glassware

134

C 5 minutes 30 minutes

to 80

o

C

MELT/FREE STEAM Melt/

Free Steam

105

C 30 minutes 20 minutes

to 80

o

C

INSTRUMENT Instruments 134

C 5 minutes 30 minutes

to 80

o

C

Porous Load Machine – Non Medical Device

OPERATING CYCLE

NAME

CYCLE OR

LOAD TYPE

STERILIZING

TEMPERATURE

STERILIZING

TIME

DRYING

RATE

FABRICS Porous 134 3mins 3mins but

can be

extended

FABRICS Porous 121 15mins 15mins

INSTRUMENT Porous 134

C 3 minutes 3mins but

can be

extended

INSTRUMENT Porous 121

C 15 minutes 15mins

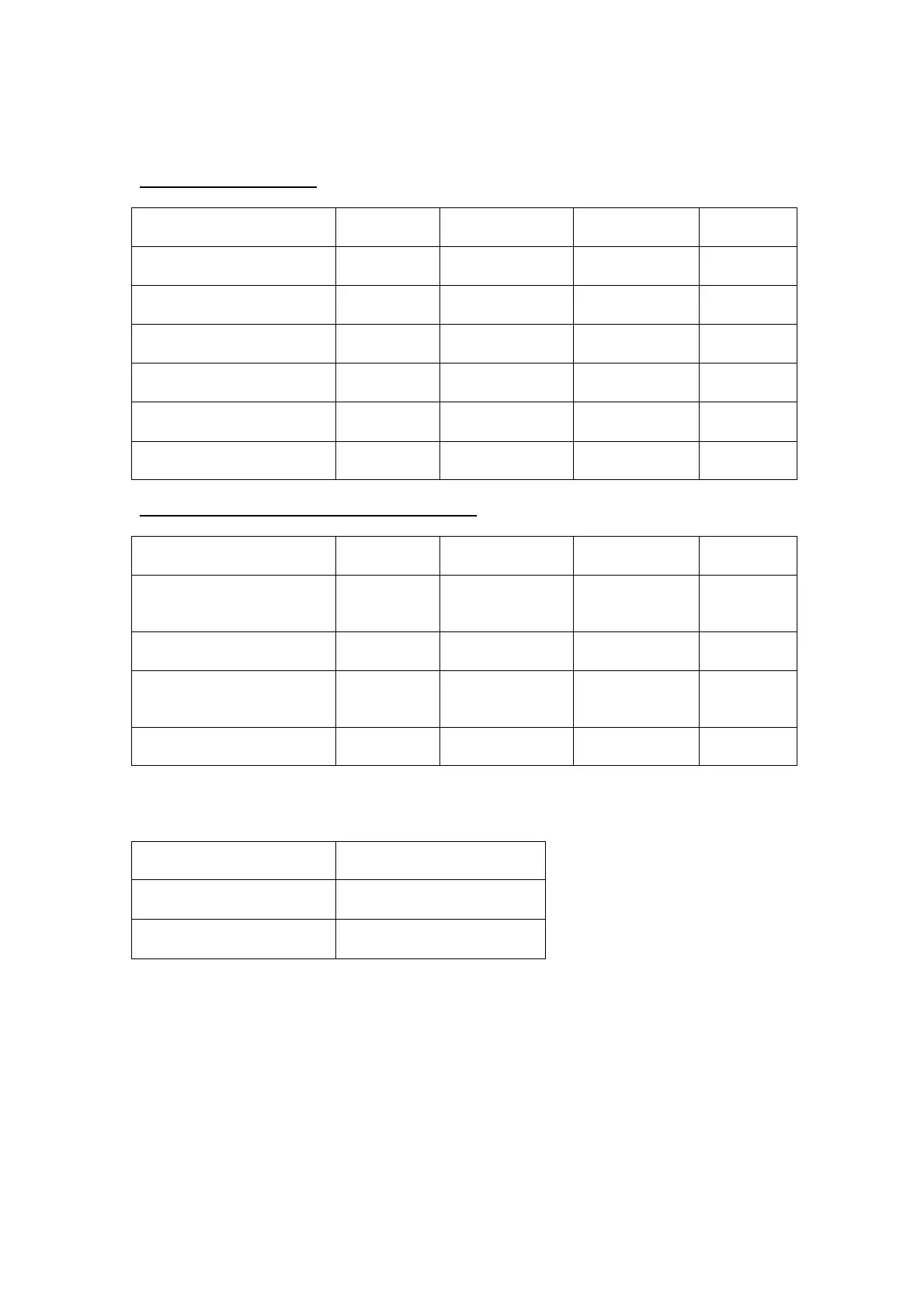

The following test cycles are also available through the control system. They can only be

carried out when there is no operating cycle in progress.

TEST CYCLE

NAME

TEST PURPOSE

LOCK/UNLOCK Check functioning of door

mechanism

LEAK TEST (vacuum

models only)

Check pressure leak rate

The LEAK TEST on Vacuum/Porous load models has two stages:

• Vac – a vacuum is pulled in the chamber

• Test – the chamber is sealed off.

Each stage is activated alternately by touching the PUMP button on the Leak Test screen of

the control system. The test ends when the FINISH button is touched. The leak test logs

time, pressures and temperature at the start and end of each stage, when requested by the

operator using the PRINT/LOG button.

Loading...

Loading...