59

ENGLISH

WARNING!

WARNING!

Lower position numbers decrease engine RPM in steps of 200 RPM and higher

position numbers increase it in steps of 200 RPM.

EXAMPLE: Calibration screw is set at position 4 and is changed to position 6:

So maximum engine RPM is increased by 400 RPM.

Adjust as follows: (only if calibrations are changed)

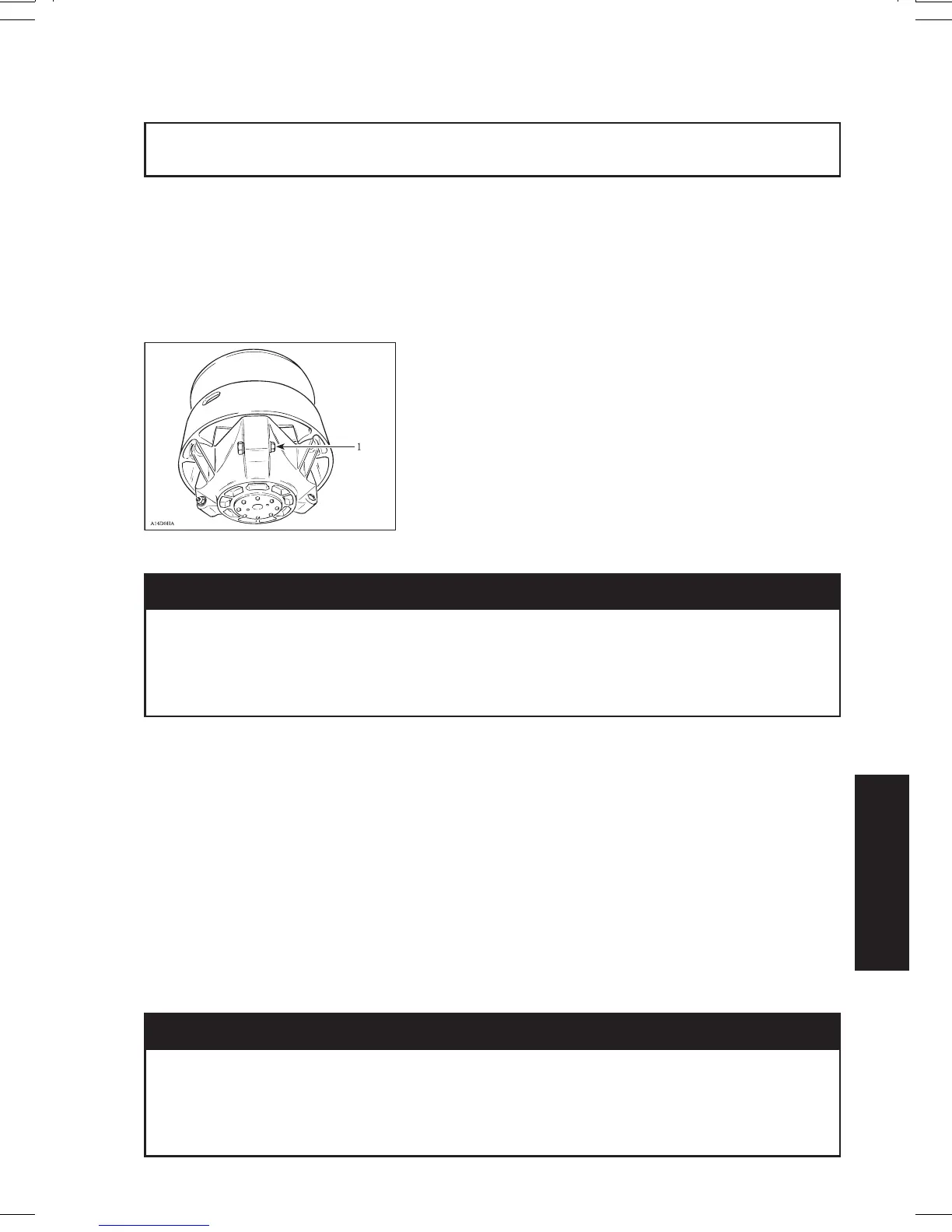

Loosen locking nut enough to pull calibration screw partially out and adjust to

desired position. Do not completely remove the locking nut. Torque nut to 10 Nm.

CAUTION: Do not completely remove calibration screw otherwise inside washer

will fall off. Always adjust all 3 calibration screws and make sure they are all set

at the same number.

1. Loosen just enough to permit rotating of calibrate screw

Always reinstall belt guard. Do not operate engine with hood open or belt

guard removed. Improper servicing, modification or poor adjustment may affect

drive pulley performance and belt life. Refer to an authorized Lynx dealer.

Drive belt condition

Inspect belt for cracks, fraying or abnormal wear (uneven wear, wear on one side,

missing cogs, cracked fabric). If abnormal wear is noted, probable cause could

be pulley misalignment, excessive RPM with frozen track, fast starts without

warm-up period, burred or rusty sheave, oil on belt or distorted spare belt. Con-

tact an authorized Lynx dealer.

Check the drive belt width. Replace the drive belt if width is less than the mini-

mum width recommended in TECHNICAL DATA.

Brake condition

The brake mechanism on your snowmobile is an essential safety device. Keep

this mechanism in proper working condition. Above all, do not operate the

snowmobile without an effective brake system. Periodically verify the conditi-

on/wear of the brake pads.

Loading...

Loading...