61

ENGLISH

ment screws if required. If correct tension is unattainable, contact an authorized

Lynx dealer.

Do not try to check the tension with engine on. Turn ignition switch to OFF. Do

not touch rotating track, it may cause injuries.

Alignment

Before checking track alignment, ensure that the track is free of all particles

which could be thrown out while track is rotating. Keep hands, tools and clothing

clear of track.

Start the engine and accelerate slightly so that track barely turns. This must be

done in a short period of time (15 to 20 seconds). Check that the track is well

centred.

Check that the track is well centred; equal distance on both sides between edges

of track guides and slider shoes.

Stop engine prior to adjusting. Loosen rear idler wheel retaining screws. Tighten

teh adjustment screw on side where the slider shoe is the farthest from the track

insert guides.

Tighten lock nuts and retaining screws.

Tighten the nuts properly. If lock nuts or adjustment screws are not tightened

properly, the track may become loose and get damaged.

Restart engine and rotate track slowly to recheck alignment.

Reposition snowmobile on ground.

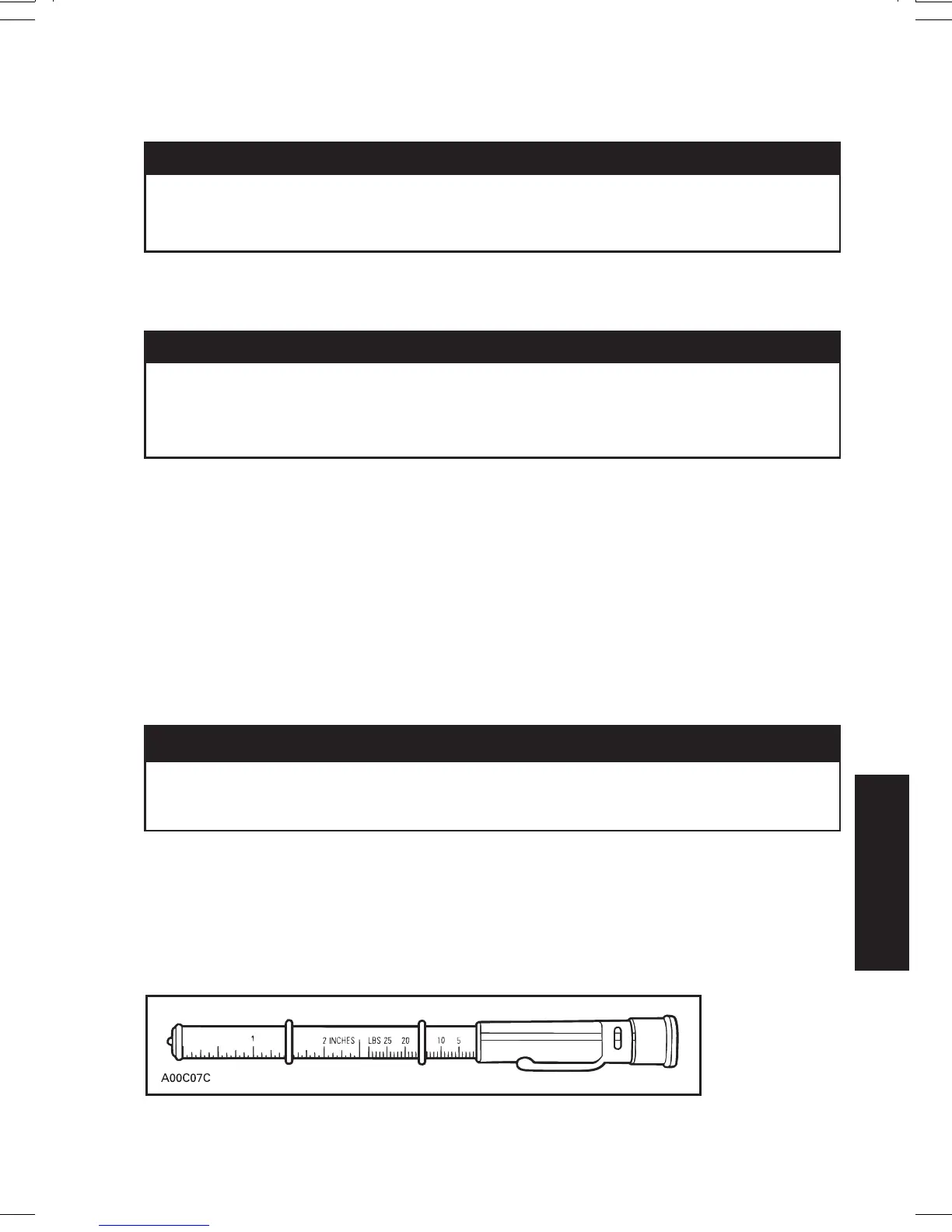

NOTE: A belt tension tester (P/N 414 348 200) may be used to measure deflecti-

on as well as force applied.

Belt tension tester

WARNING!

WARNING!

WARNING!

Loading...

Loading...