46

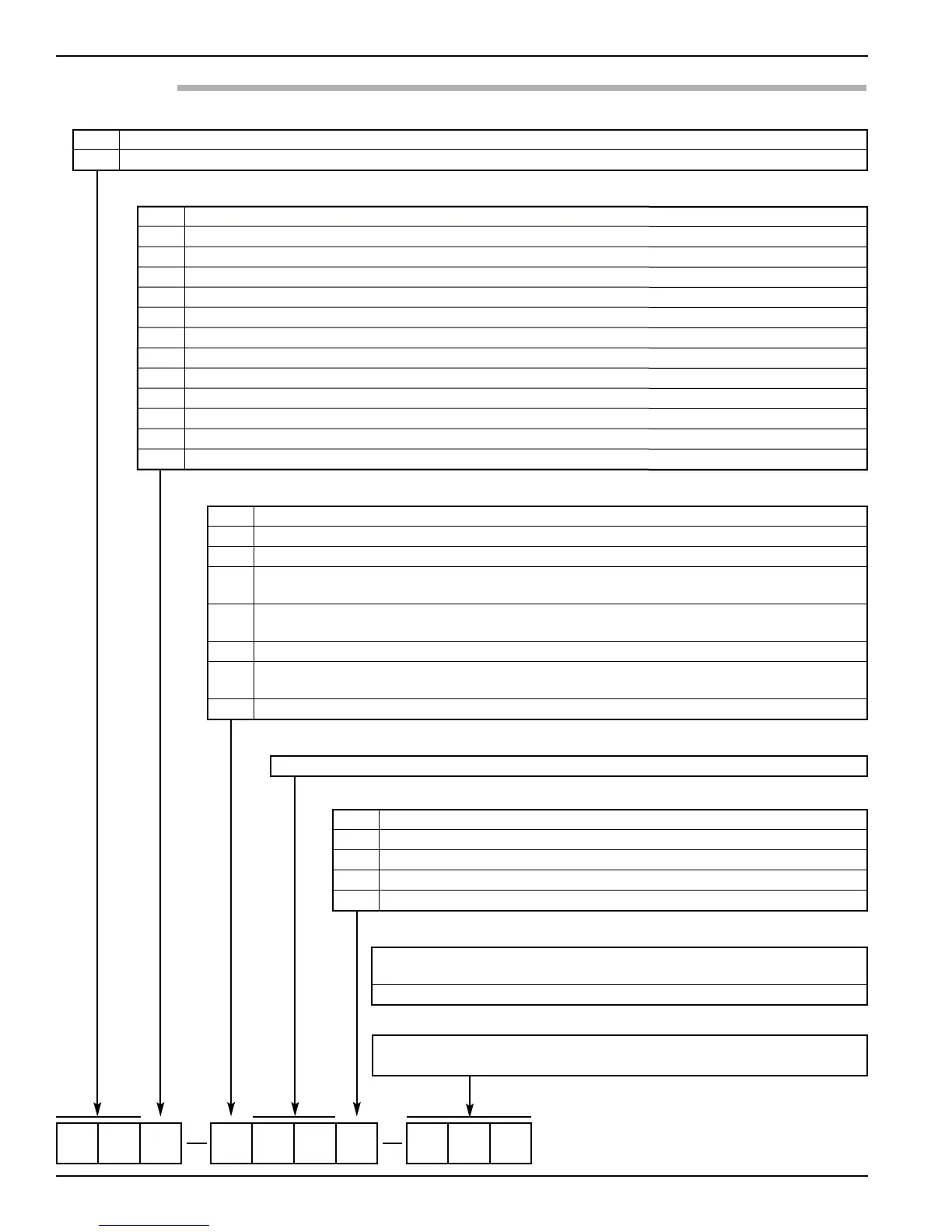

57-645 Eclipse Guided Wave Radar Transmitter - PROFIBUS PA

™

Refer to pages 47 and 48 for selections

24" to 240" (60 cm to 610 cm) (7xQ and 7xS: 180" (457 cm) maximum)

(unit of measure is determined by second digit of Model Number)

Examples: 24 inches = 024; 60 centimeters = 060

0 Viton

®

GFLT

1 EPDM (Ethylene Propylene Rubber)

2 Kalrez 4079

8 Aegis PF128

N None (Use with probes 7xD, 7xP, 7xF-E, 7xF-F, 7xF-P)

A 316/316L stainless steel

B Hastelloy C, Configuration/Style codes A, B, D, F, G, P, R and T only

C Monel, Configuration/Style codes A, B, D, F, G, P, R and T only

E

Hygienic, 316/316L stainless steel (20 R

a

finish), Configuration/Style code F only,

Process connections codes 4P, 5P, and 6P only

F

PFA faced flange, 2" to 4", 150# to 300#, Configuration/Style code F only,

Process connection codes 43, 44, 53, 54, 63, 64, DA, DB, EA, EB, FA, and FB only

K 316/316L stainless steel probe and process connection, ASME B31.1 specifications (model 7xS only)

P

Paint Probe, 316/316L SS,

3

⁄4" process connection or larger

Configuration/Style code F only: maximum length 72"

4 PFA insulated rod, 2" NPT process connection or larger, Configuration/Style code F only

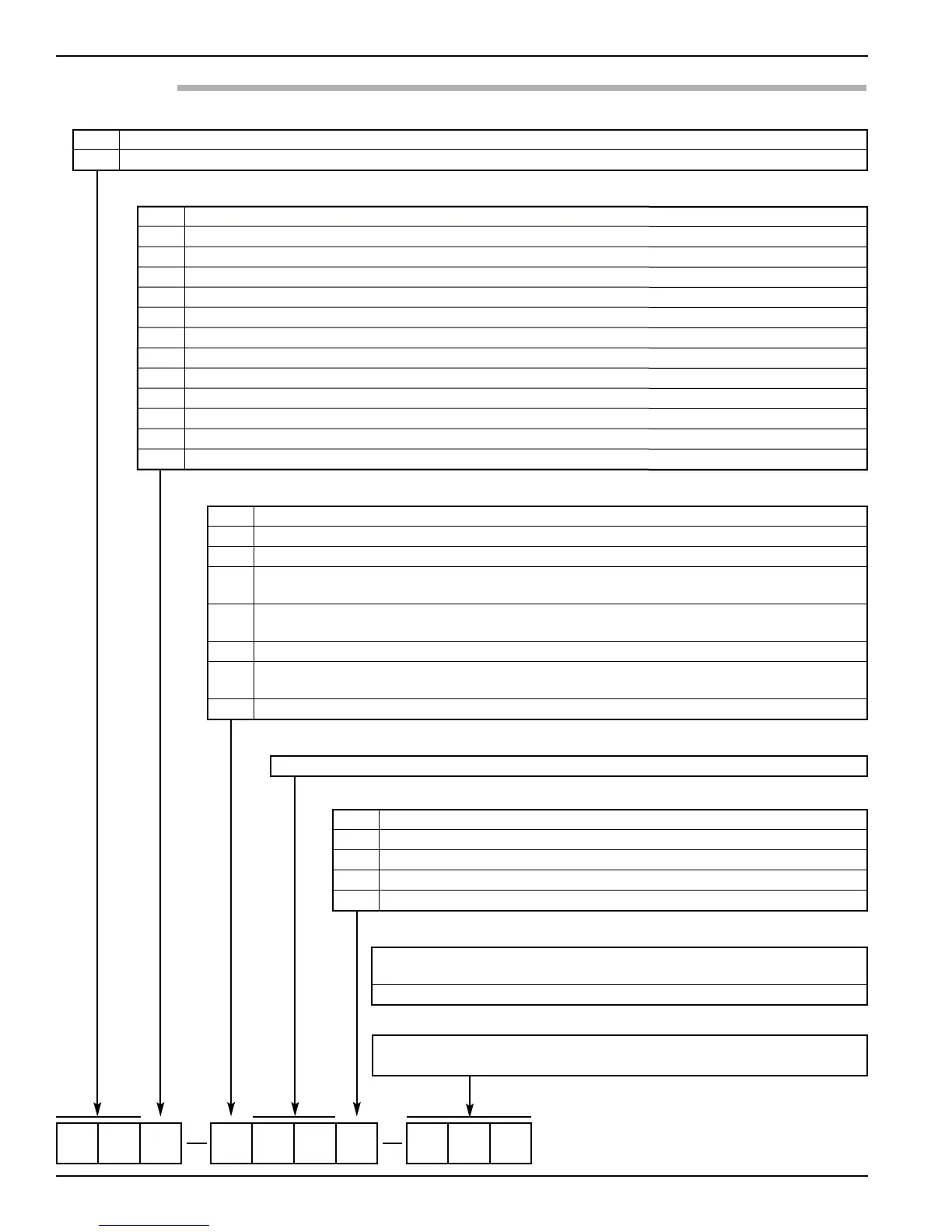

7E Eclipse GWR probe, English unit of measure

7M Eclipse GWR probe, Metric unit of measure

6' to 75' (2 to 22 m) (unit of measure is determined by second

digit of Model Number) Examples: 30 feet = 030; 10 meters = 010

A

Co

a

xi

a

l

,

3

⁄4

"

p

ro

c

e

ss

c

o

n

n

e

c

ti

o

n

o

r

l

a

r

g

e

r

(

Di

e

l

e

c

tr

i

c

r

a

n

g

e

≥

1

.

4

)

B

T

w

i

n

R

o

d

,

2

"

NP

T

o

r

3

"

fl

a

n

g

e

d

p

ro

c

e

ss

c

o

n

n

e

c

ti

o

n

o

r

l

a

r

g

e

r

(

Di

e

l

e

c

tr

i

c

r

a

n

g

e

≥

1

.

9

)

D

Co

a

xi

a

l

,

Hi

g

h

T

e

m

p

e

r

a

tu

re

/

Hi

g

h

P

re

ssu

re

,

3

⁄4

"

p

ro

c

e

ss

c

o

n

n

.

o

r

l

a

r

g

e

r

(

D

i

e

l

e

c

tr

i

c

r

a

n

g

e

≥

1

.

4

)

F S

i

n

g

l

e

R

o

d

,

R

i

g

i

d

,

2

"

p

ro

c

e

ss

c

o

n

n

e

c

ti

o

n

o

r

l

a

r

g

e

r

(

D

i

e

l

e

c

tr

i

c

r

a

n

g

e

≥

1

.

9

)

J

S

i

n

g

l

e

R

o

d

,

R

i

g

i

d

,

Hi

g

h

T

e

m

p

e

r

a

tu

re

/

Hi

g

h

P

re

ssu

re

(

Di

e

l

e

c

tr

i

c

r

a

n

g

e

≥

1

.

9

)

P

Co

a

xi

a

l

,

Hi

g

h

P

re

ssu

re

,

3

⁄4

"

p

ro

c

e

ss

c

o

n

n

e

c

ti

o

n

o

r

l

a

r

g

e

r

(

Di

e

l

e

c

tr

i

c

r

a

n

g

e

≥

1

.

4

)

Q Co

a

xi

a

l

,

Ho

t

W

a

te

r

/

S

te

a

m

,

2

"

p

ro

c

e

ss

c

o

n

n

e

c

ti

o

n

o

r

l

a

r

g

e

r

(

Di

e

l

e

c

tr

i

c

r

a

n

g

e

≥

1

0

)

R

Co

a

xi

a

l

,

O

ve

r

fi

l

l

,

3

⁄4

"

p

ro

c

e

ss

c

o

n

n

e

c

ti

o

n

o

r

l

a

r

g

e

r

(

Di

e

l

e

c

tr

i

c

r

a

n

g

e

≥

1

.

4

)

S

Co

a

xi

a

l

,

Ho

t

W

a

te

r

/

S

te

a

m

,

3

⁄

4

"

p

ro

c

e

ss

c

o

n

n

e

c

ti

o

n

o

r

l

a

r

g

e

r

(

D

i

e

l

e

c

tr

i

c

r

a

n

g

e

≥

1

0

)

1

S

i

n

g

l

e

R

o

d

,

F

l

e

xi

b

l

e

,

2

"

p

ro

c

e

ss

c

o

n

n

e

c

ti

o

n

o

r

l

a

r

g

e

r

(

D

i

e

l

e

c

tr

i

c

r

a

n

g

e

≥

1

.

9

)

2

S

i

n

g

l

e

R

o

d

,

F

l

e

xi

b

l

e

B

u

l

k

S

o

l

i

d

,

2

"

p

ro

c

e

ss

c

o

n

n

e

c

ti

o

n

o

r

l

a

r

g

e

r

(

Di

e

l

e

c

tr

i

c

r

a

n

g

e

≥

4

.

0

)

5 Twi

n R

od

,

Fl

e

xi

b

l

e

B

ul

k S

ol

i

d

,

2"

p

roc

e

ss c

onne

c

ti

on or

l

a

rge

r

(D

i

e

l

e

c

tr

i

c

r

a

nge

≥

1.

9)

7 Twi

n R

od

Fl

e

xi

b

l

e

,

2"

NP

T or

3"

fl

a

nge

d

p

roc

e

ss c

onne

c

ti

on or

l

a

rge

r

(D

i

e

l

e

c

tr

i

c

r

a

nge

1.

9–10)

Loading...

Loading...