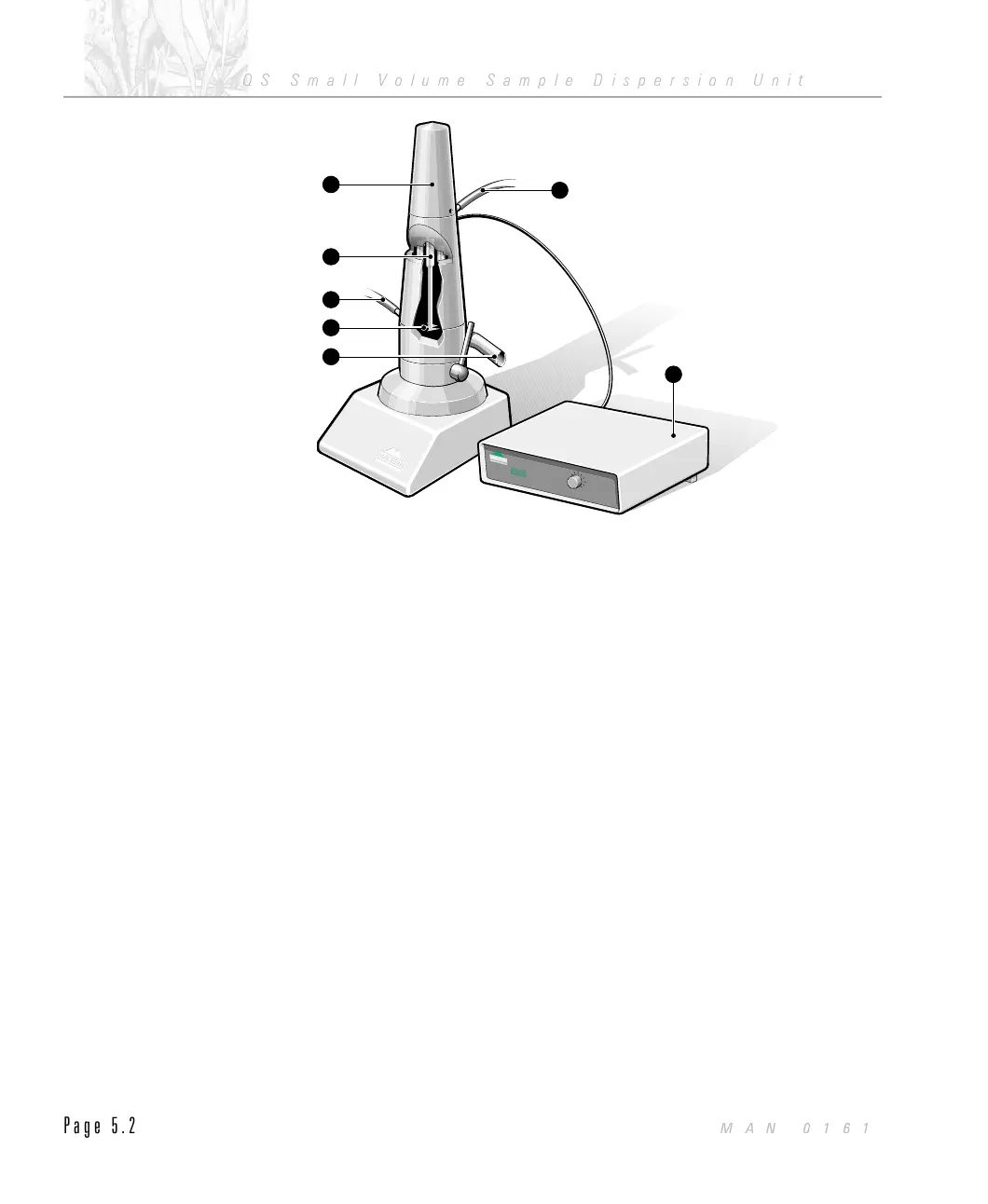

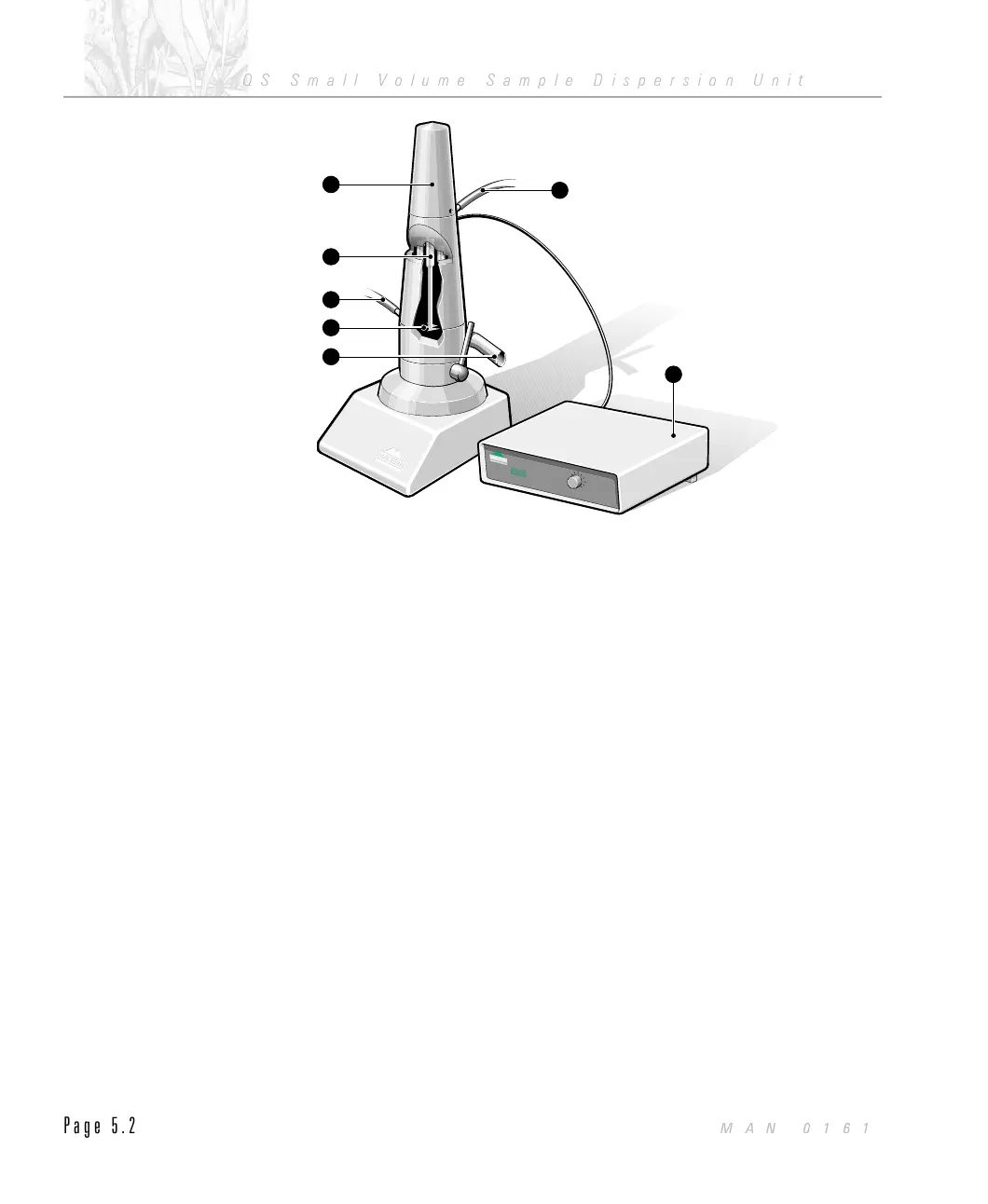

The Dispersion Unit comprises an electric motor À that drives a stirrer  and

impeller à in the dispersion tank to provide a simultaneous stirring and pumping

action. The sample is manually added to the tank using a pipette. The stirrer  is

provided to agitate the sample and stop it from separating or settling. The pump

impeller à forces the sample from the sample out port Æ to the cell located in

the Mastersizer, via the sample tubing.

When the cell is full of sample, the pressure exerted by the pump forces the

sample through the outlet port located at the top of the cell. The sample then

passes back to the Dispersion Unit, via the sample tubing and the sample return

port Å.

In this way the sample is continuously agitated and kept circulating through the

cell. Note that the sample is always pumped to the cell in an upwardly direction.

This is to allow any trapped air to percolate up through the system.

On completion of a measurement the drain Ä is used to empty the tank, tubes

and cell under gravity.

How to make a measurement using the Accessory

As described earlier, the purpose of the Accessory is to prepare the sample and

then deliver it to the Mastersizer so that it can be measured. The measurement

stages carried out by the Mastersizer under the control of the Malvern software

include the following:

Dispersion Unit Controller

INSTRUMENTS

Dispersion Unit Controller

INSTRUMENTS

RPM

StirrerSpeed

1

Small Volume Sample Dispersion Unit

INSTRUMENTS

Small Volume Sample Dispersion Unit

INSTRUMENTS

4

7

6

2

5

3

ILL 3047

CHAPTER 5

QS Small Volume Sample Dispersion Unit

Page 5.2

MAN 0161

Loading...

Loading...