HYDRAULIC SYSTEM 5540F/YB5515 SERVICE MANUAL

4-50 Published 10-21-2010, Control# 198-04

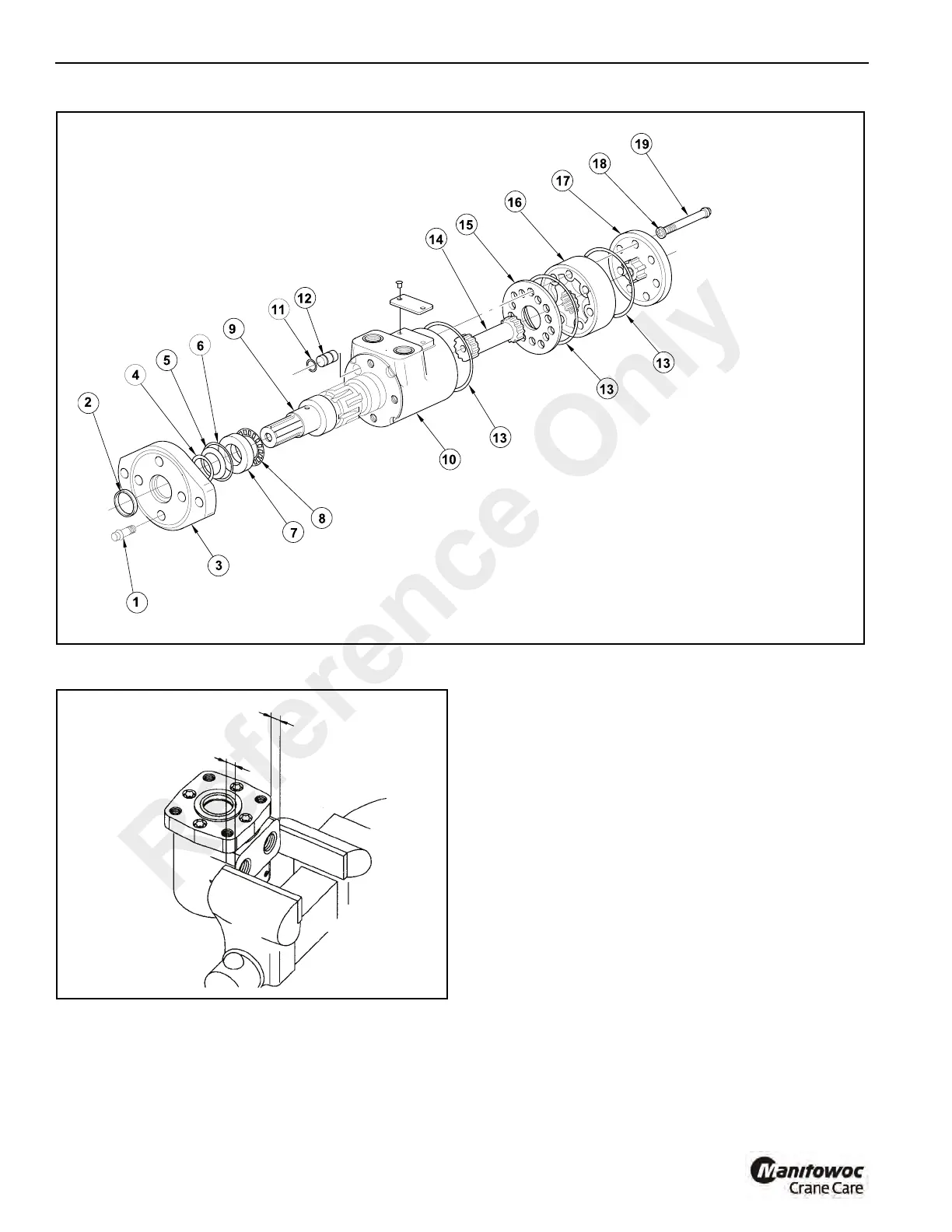

11. Remove four capscrews 1 from mounting flange 3.

These screws were installed with Loctite to hold them in

place.

The screws will require 300 - 400 lb-in (35 - 45 Nm) of

torque to break loose and 100 lb-in (11 Nm) torque to

remove. Do not use an impact wrench on the screws.

This could result in rounded heads or broken sockets.

NOTE: If a torque higher than given above is required to

break the capscrews loose, apply heat according to

the following:

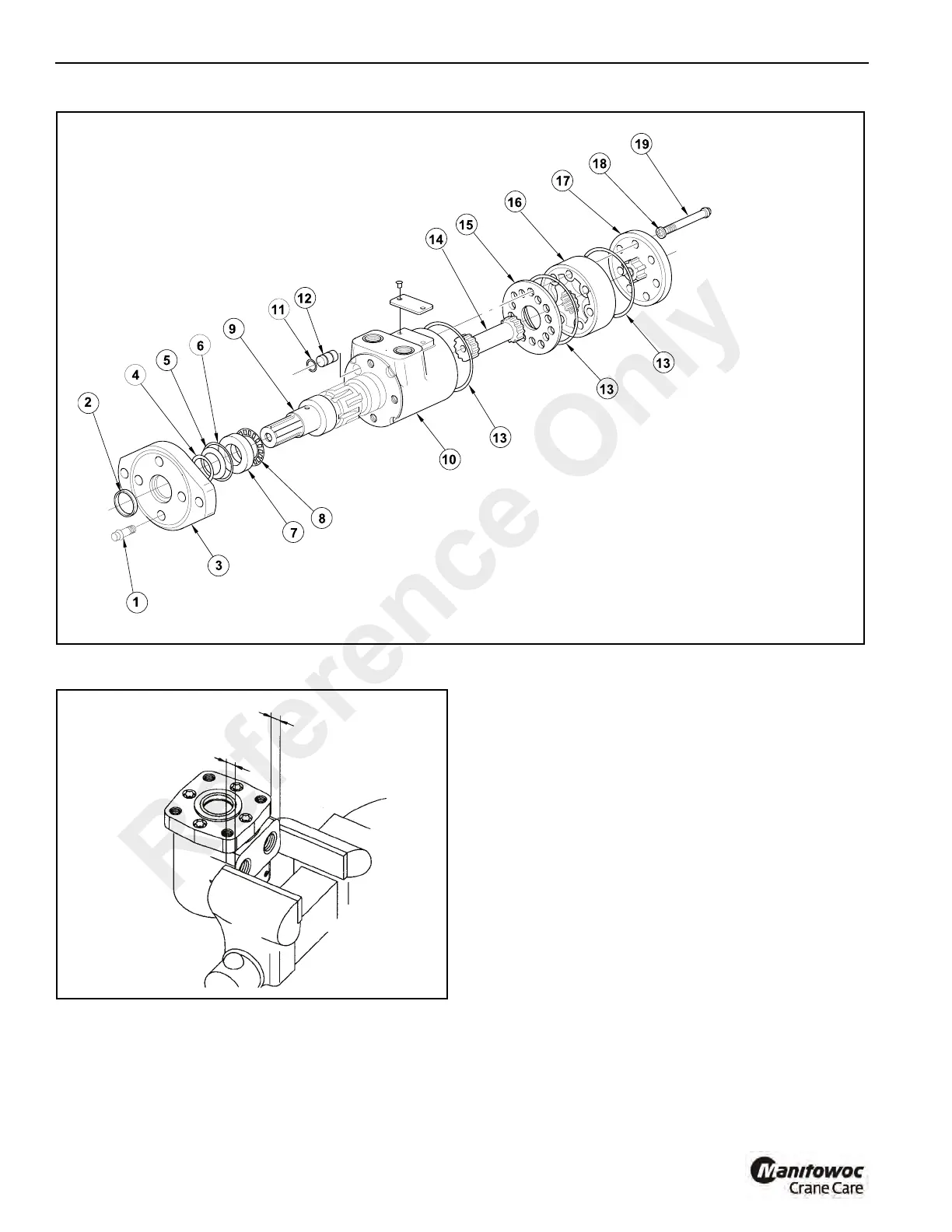

When heated, Loctite partially melts. This reduces

the torque required to remove screw. Use a small

flame propane torch to heat a small area of the

housing where the screws enter. Figure 4-51. Be

careful not to overheat the housing and damage

the motor. Gradually apply torque to the capscrew

with a socket wrench as heat is applied for 8 to 10

seconds. As soon as the screw breaks loose,

remove the heat from the housing. Continue

turning the screw until it is completely removed.

Repeat for other capscrews.

12. Carefully remove flange 3 Figure 4-49 from housing 10.

a0949

FIGURE 4-49

1. Screw (4)

2. Exclusion Seal

3. Mounting Flange

4. Backup Ring *

5. Shaft Pressure Seal *

6. Seal *

7. Bearing Race

8. Thrust Needle Bearing

9. Output Shaft

10. Housing

11. O-Ring

12. Plug

13. Seal (3) *

14. Drive Shaft

15. Spacer Plate

16. Gerotor Set

17. End Cap

18. Seal Washer (7) *

19. Screw (7)

* Included In Seal Kit

Swing Motor

a0764

FIGURE 4-50

1/2” (13 mm)

1/2” (13 mm)

Reference Only

Loading...

Loading...