GROVE Published 10-21-2010, Control# 198-04 7-43

5540F/YB5515 SERVICE MANUAL TRANSMISSION AND TORQUE CONVERTER

first, followed by 3rd/4th gear selector rod. To ensure

that the mainshaft locates with the output shaft it will be

necessary to push on tool T to keep the shaft correctly

aligned. Rotate the output shaft S back and forth to

engage the gears on the layshaft. Do not use excessive

force when fitting the casing.

31. Apply Loctite 242 to bolts 31, (Figure 7-56) and torque to

42 lb ft (57 Nm).

32. Remove service tool at position B. Install the detent ball

and spring. Apply Loctite 242 to selector detent plug,

install and tighten.

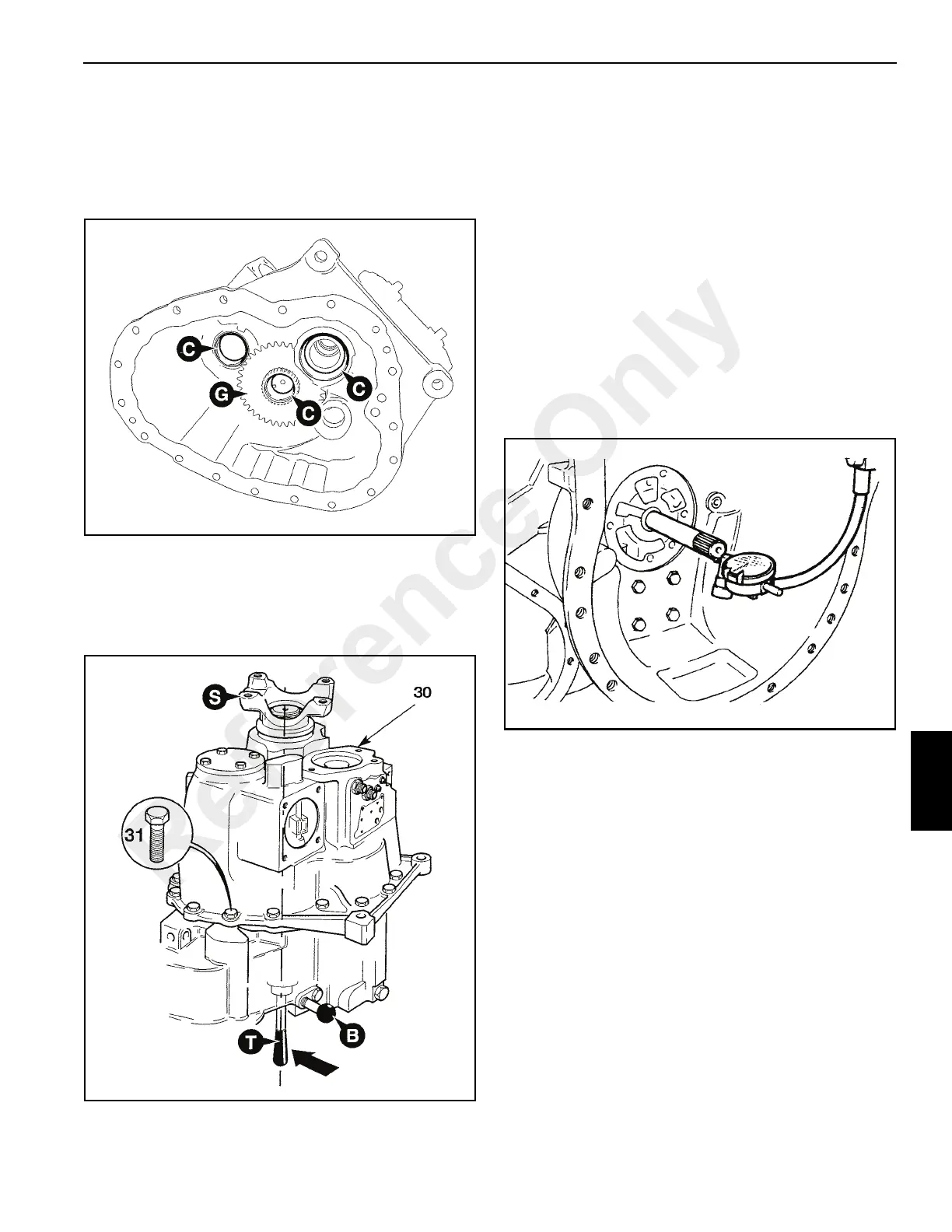

33. End Float Checking - Reverser Unit (Figure 7-57)

Measure end float of forward/reverse shaft which should be

0.0004 to 0.006 in (0.01 to 0.16 mm).

NOTE: Rotate shaft while measuring to seat bearings fully.

Position pointer of dial test indicator (DTI) on the

chamfer of the shaft, not the end face. This will

ensure a constant reading is given.

The forward/reverse shaft and its associated components

are manufactured using a 'Set-right' system. Provided

components are assembled correctly, the end float will be

within the limits given above.

If there is no float, or too much end float, separate the

casings and check that the bearings inner and outer cups are

fitted correctly. If the forward/reverse shaft and clutch

assemblies have been dismantled check that the assembly

has been carried out correctly.

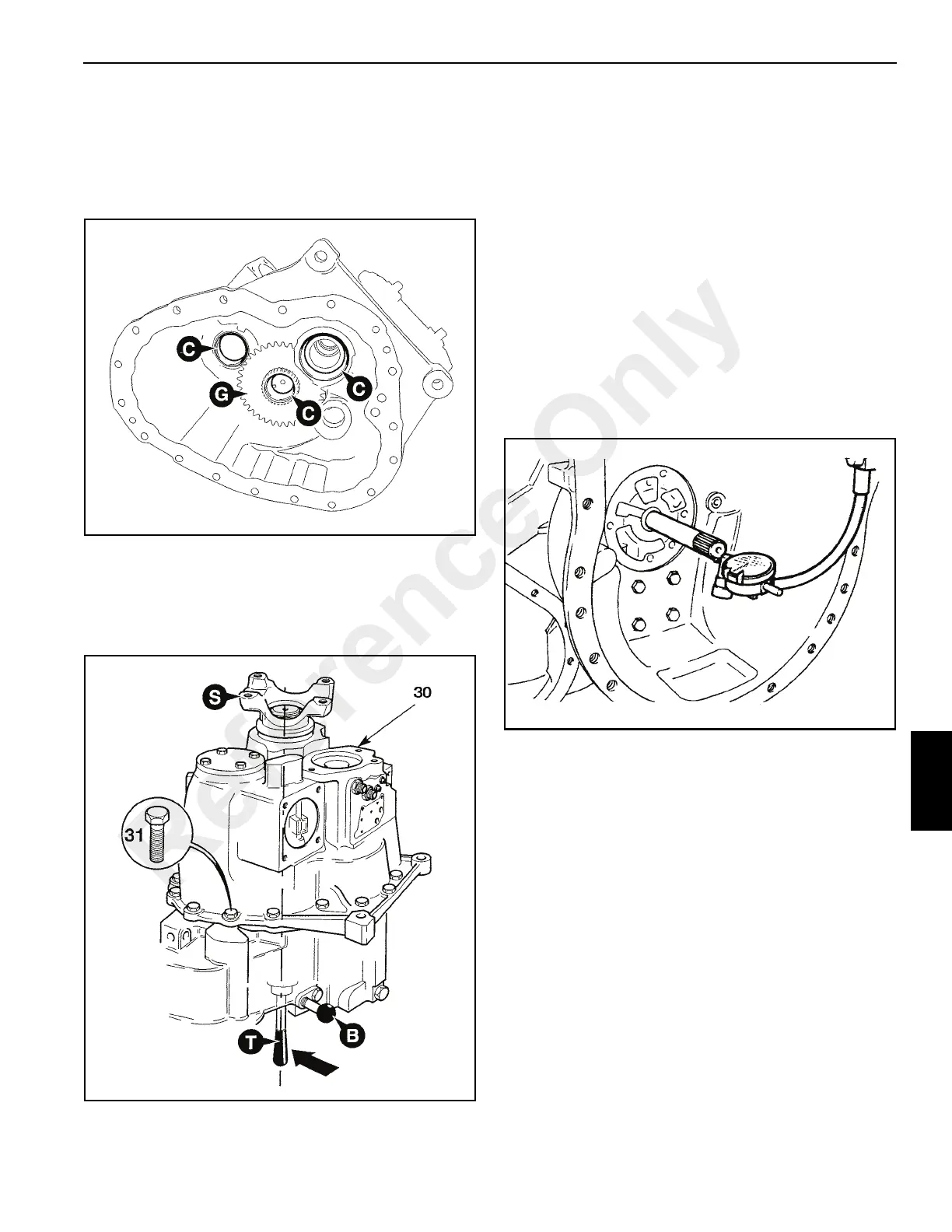

34. End Float Setting - Mainshaft (See Figure 7-55 and

Figure 7-56)

If the mainshaft, output shaft and/or associated bearings

have been renewed, the shaft end float must be reset.

a. Remove the torque converter housing and position

the gearbox to gain access to setting ring A.

b. Using service tool 892/01079 tighten the setting ring

to 18.4 Ib ft (25 Nm) whilst at the same time rotating

the shaft via the output yoke (a gear must be

engaged). Do not over tighten the ring.

Overtightening will damage the bearings.

c. Undo the ring a small amount to obtain a shaft end

float of 0.001 to 0.003 in (0.03 to 0.08 mm). To

measure the end float screw in a bolt at the

threaded hole in the end of the shaft. Set up a DTI

with the probe on the chamfer of the shaft. Zero the

DTI. Rotate the shaft and at the same time pull up

on the bolt, noting the reading on the DTI. Screw the

ring in or out until the end float is correct.

Reference Only

Loading...

Loading...