GROVE Published 10-21-2010, Control# 198-04 7-51

5540F/YB5515 SERVICE MANUAL TRANSMISSION AND TORQUE CONVERTER

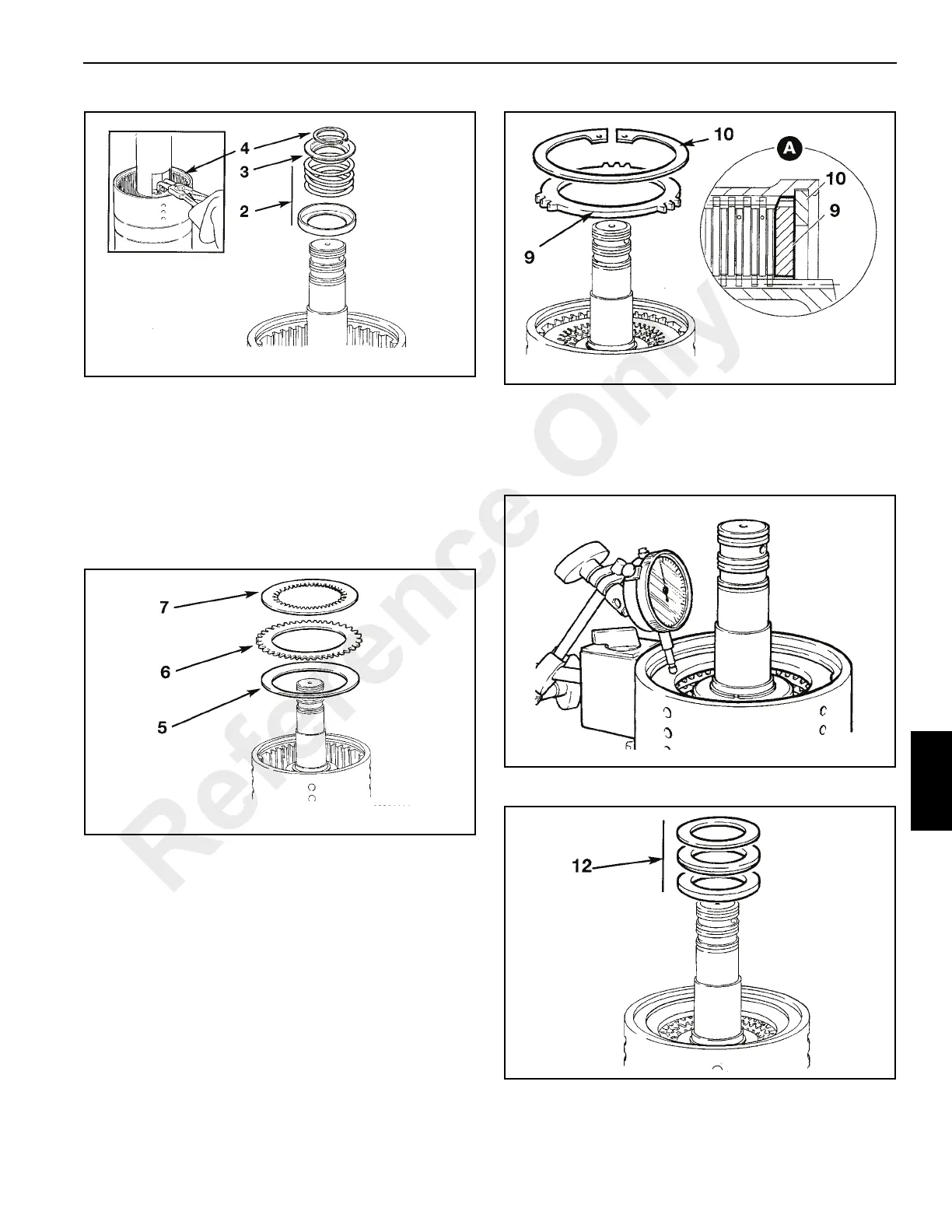

5. Install the disc spring assembly. (5, Figure 7-83). Install

the assembly so that the outer diameter curves away

from the clutch piston.

6. Firstly, install one counter plate 6.

7. Install one friction plate 7 followed by one steel counter

plate.

8. Continue installing alternating friction and plain steel

plates, finishing with a friction plate 7.

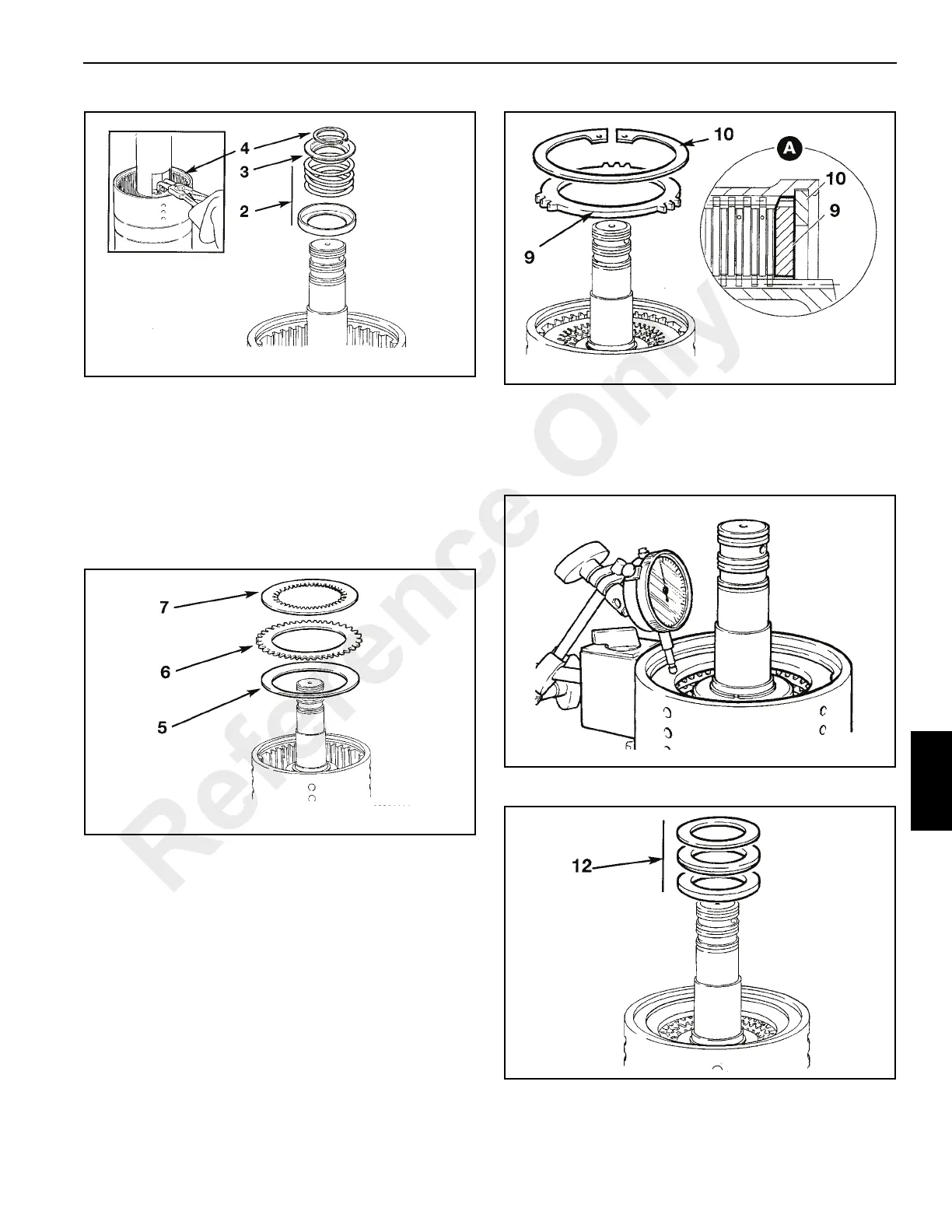

9. Install the pressure (end) plate (9, Figure 7-84). Make

sure that the chamfered face is fitted facing the clutch

pack as shown at A. Make sure that the prongs on the

pressure plate DO NOT locate in the large grooves in

the hub (the ones with drilled holes).

10. Install the clutch friction/counter plates retaining circlip

10. Using an air line blow air down the shaft oil inlet hole

and check the piston and clutch pack is free to operate

smoothly.

11. Using a dial test indicator, as shown (Figure 7-85),

measure the end float of the pressure (end) plate, which

should be 0.126 to 0.173 in (3.2 to 4.4 mm). Install shim

between the retaining circlip and pressure (end) plate to

correct end float inaccuracies.

12. Install thrust bearing and thrust washers.

13. Install gear and splined hub assembly (13, Figure 7-87).

Reference Only

Loading...

Loading...