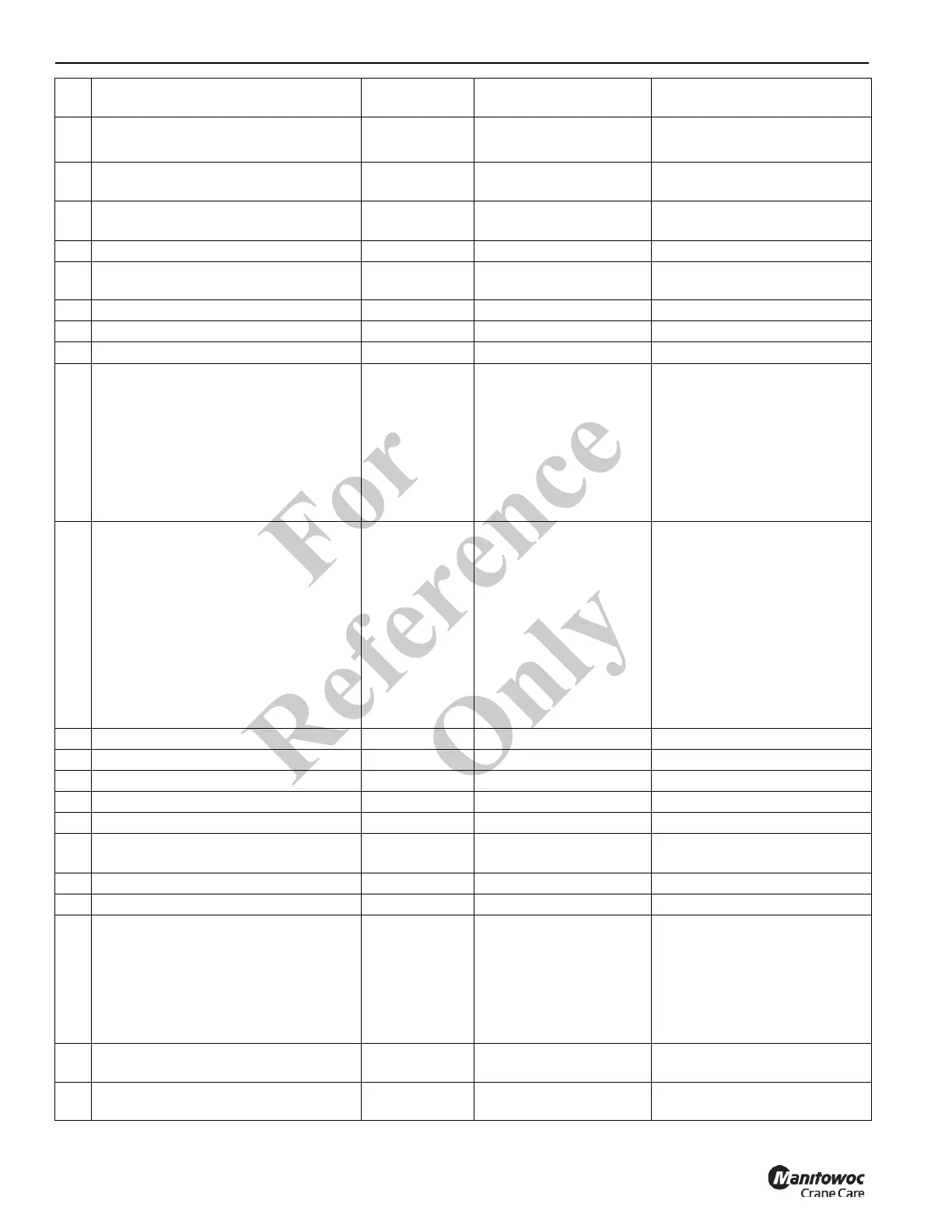

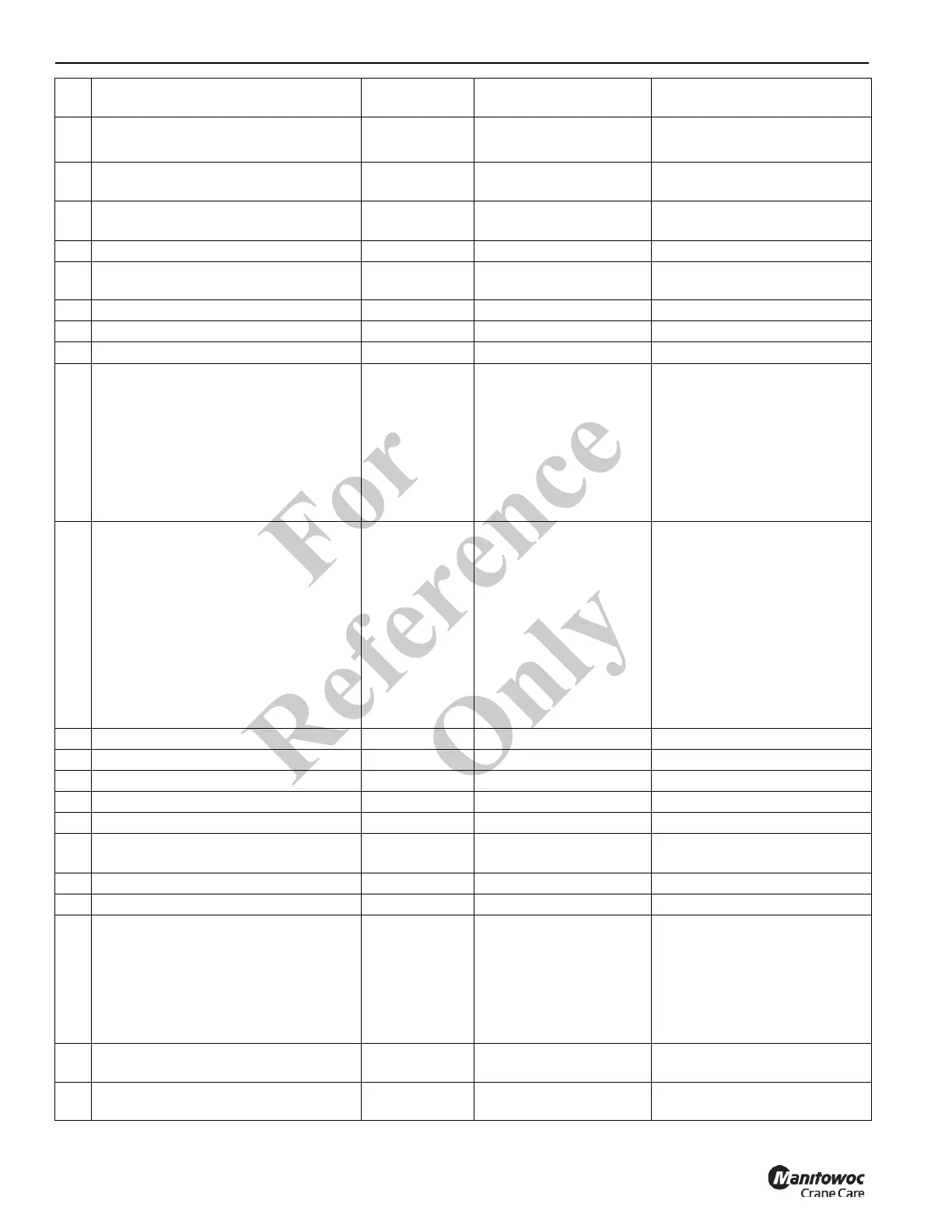

LUBRICATION PROCEDURE AND CHARTS OPERATOR MANUAL NBT60XL

5-6 Published 11-01-2020 Control # 710-00

Item Application

Recommended

Lubricant

Procedure Frequency

1 Hydraulic oil tank reservoir HYDO

Check and Fill

Change

Weekly, Fill as required

Semi-Annually

2 Hydraulic tank Oil filter Change or clean

After first 40 Hrs, Quarterly

thereafter.

3 Hydraulic tank suction filter Change or clean

After first 40 Hrs, Quarterly

thereafter.

4 Breather, Hydraulic oil reservoir Clean Monthly

5

Sheave pins: boom (5 plcs), jib (1 pl),

block (1 pl), rooster sheave (1 pl)

EP-MPG Grease gun Weekly

6 Boom pivot pin EP-MPG Grease gun Monthly

7 Lift cylinder pins - 2 ea. EP-MPG Grease gun Monthly

8 Swing bearing EP-MPG Grease gun Weekly

10 Hoist gearbox and brake GL-5

Check and Fill

Change

Check and Fill: Every 500

operating hours, or 3 months.

Change: After first 100 hours,

then every 1000 hours or

6 months thereafter.

For more information, see Hoist

Gearbox and Brake Oil, page 5-

8.

11 Swing drive gearbox GL-5

Check and Fill

Change

Check and Fill: As part of daily

crane inspection, check the

gearbox for visible leaks.

Change: After first 50 hours of

operation, every 500 hours

thereafter.

For more information, see Swing

Gearbox Oil, page 5-9.

12 Swing gear teeth EP-OGL Spray Can Monthly

13 Boom Inner, Side and Bottom Wear Pads LTG See page 5-7 Monthly or as required

14 Outrigger beams, bottom, sides LTG Brush or roller spray can Monthly or as required

15 Wire rope (loadline) EP-OGL Brush or spray Semi-Annually

17 Swing Motor Pinion Bearing EP-MPG Grease Gun Sparingly every 50 hours

18a

Synchronizing Sheaves: Top of 2nd

Section

EP-MPG Grease Gun Weekly

18b Extend Sheaves: Side of 4th Section EP-MPG Grease Gun Weekly

18c Extend Sheaves: Opening on tele 1 EP-MPG Grease Gun Weekly

19

Retract Sheaves, Rear of sections 2, 3,

and 4: Fully retract the booms until the

retract sheave grease fittings can be

accessed from the rear of the Booms or

extend the booms until the fittings are

visible through the access holes at the

center of boom.

EP-MPG Grease Gun Weekly

20 Extension Cables (Not Shown) WRL Spray or Brush

Any Time Boom is Disassembled

or 7 Years

21

Hydraulic tank magnetic plug (tank

bottom)

Clean

When servicing hydraulic tank,

item 1

Fo

r

Reference

Only

Loading...

Loading...