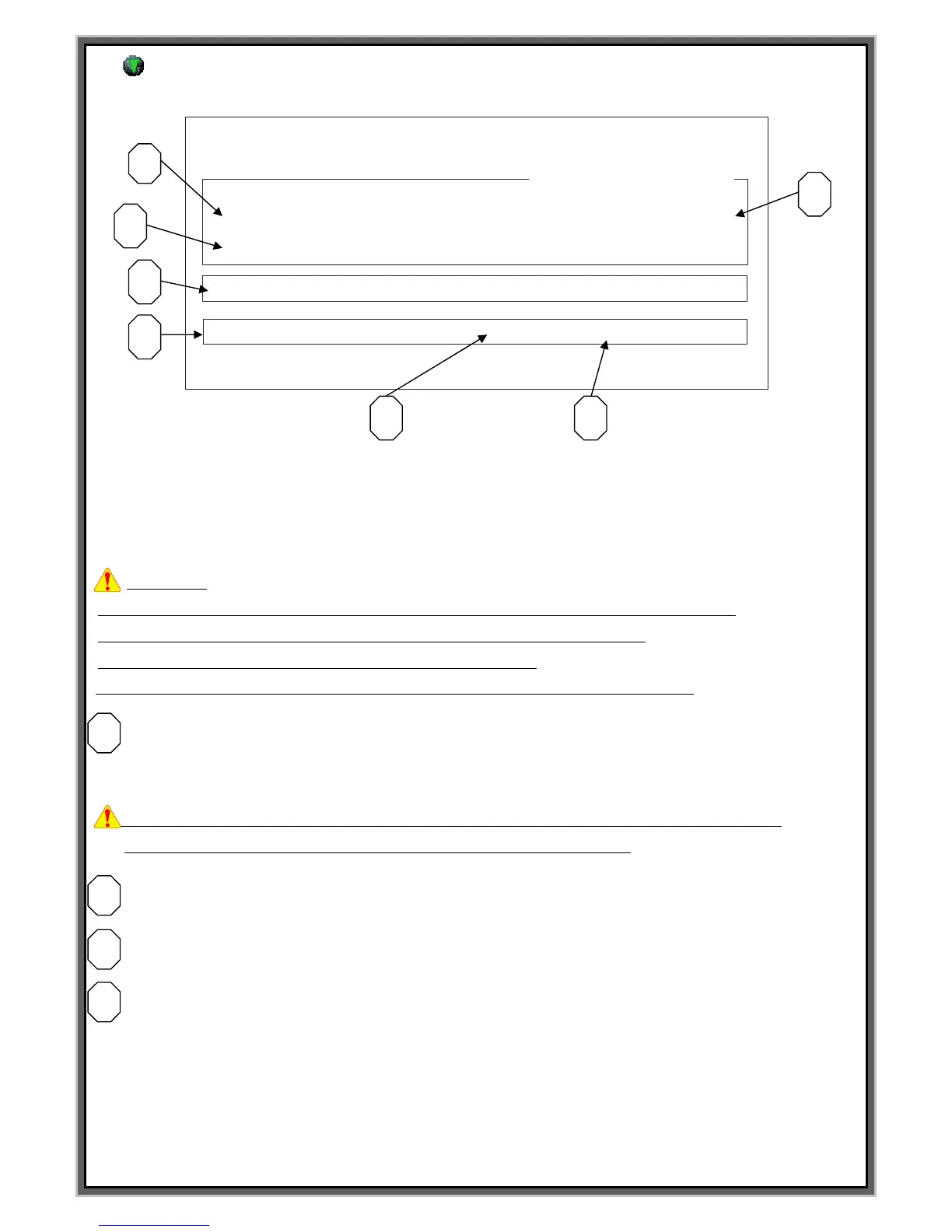

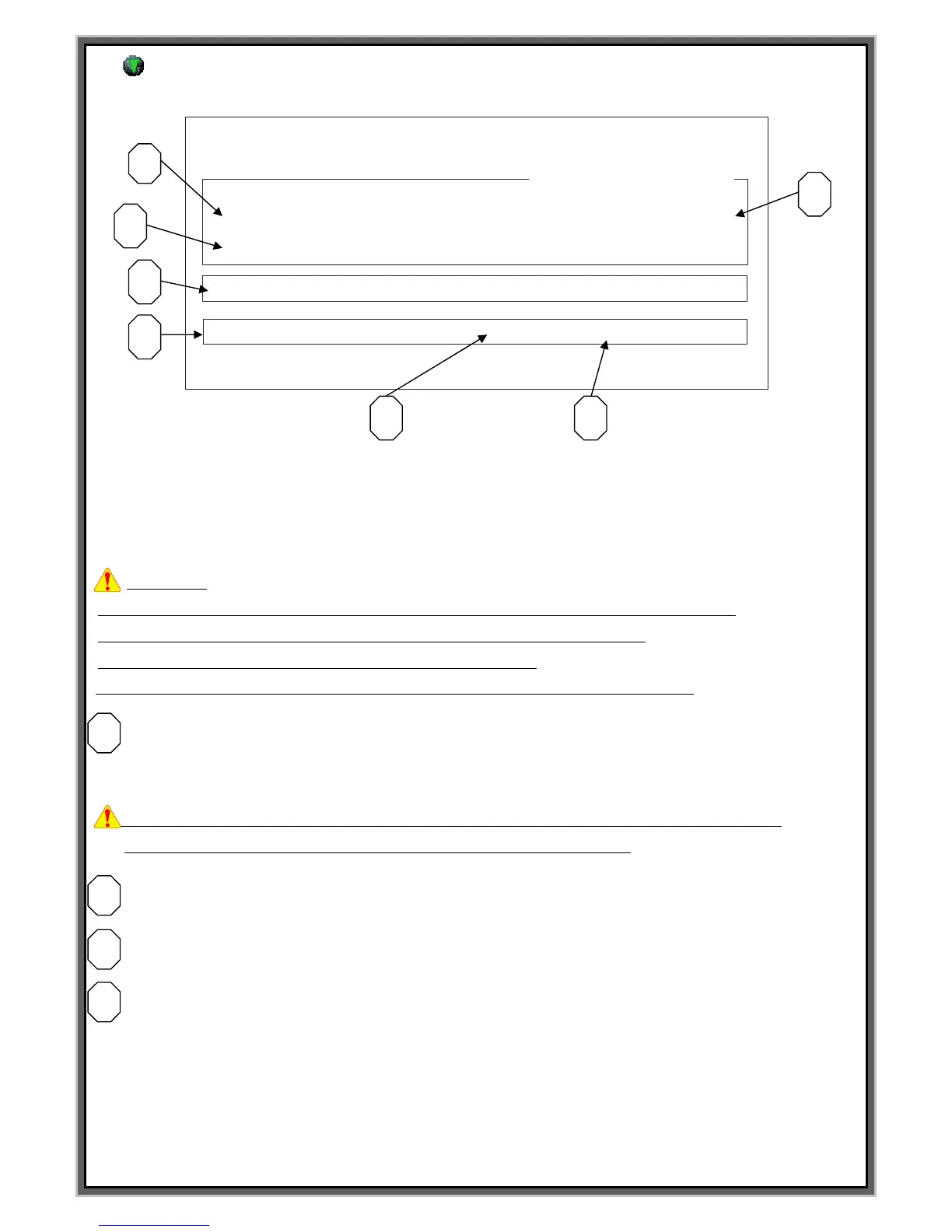

F1 : M_MENU F2 : A_MARK F3 : EDIT F4 : FILE

F5 : SETUP F6 : TEST F7 : LOAD F8 : COMM

BLK NO. [ 000 ]

PLC INPUT SIGNAL [ . . . . . . . . ] [ . . . . . . . . ]

15:15:22 0.00 STATUS [ ]

[AUTO MARKING MODE]

F9 : SIMULATION F10 : MARK F11 : HOME

MARK_UP_TO[ 00000000 ] UNIT_NO[00001713]

< CURRENT DATA >

(F2) A_MARK screen is the mode which can mark marking data which is inputted on F3 Edit mode

through PLC or external signal on the automation line.

Current marking data and signal which is inputted on PLC are indicated on the screen and

PLC IMPUT SIGNAL.

Basic interface is same as manual marking. Please use this mode when you use it on the automation line.

**Caution**

When the marking machine is ON, you must give RESET signal or press F11 on the keyboard.

READY LAMP of the controller will be ON after marking head confirm Zero point.

READY Signal of external I/O interface is happened at that time.

If the Lamp at READY is turned off, Output at READY of external I/O doesn`t happened.

MARK UP TO (Specified quantity marking) : This function allows you to set a number of

how many pieces of your product to be marked. If you set the number like [00000100] to MARK_UP_TO,

when marked quantity reached this number, the system will be stopped automatically

**Caution – In case there`s value to the MARK UP TO , UNIT END indicate to the STATUS window

and then marking doesn`t start. In this case you must make it [00000000]

<CURRENT DATA> : Indicate current marking data

UNIT NO : This menu is a counter. It indicates the marking quantity.

Check the PLC interface : In case some signal is inputted to the I/O interface, this [.] is charged [!].

Loading...

Loading...