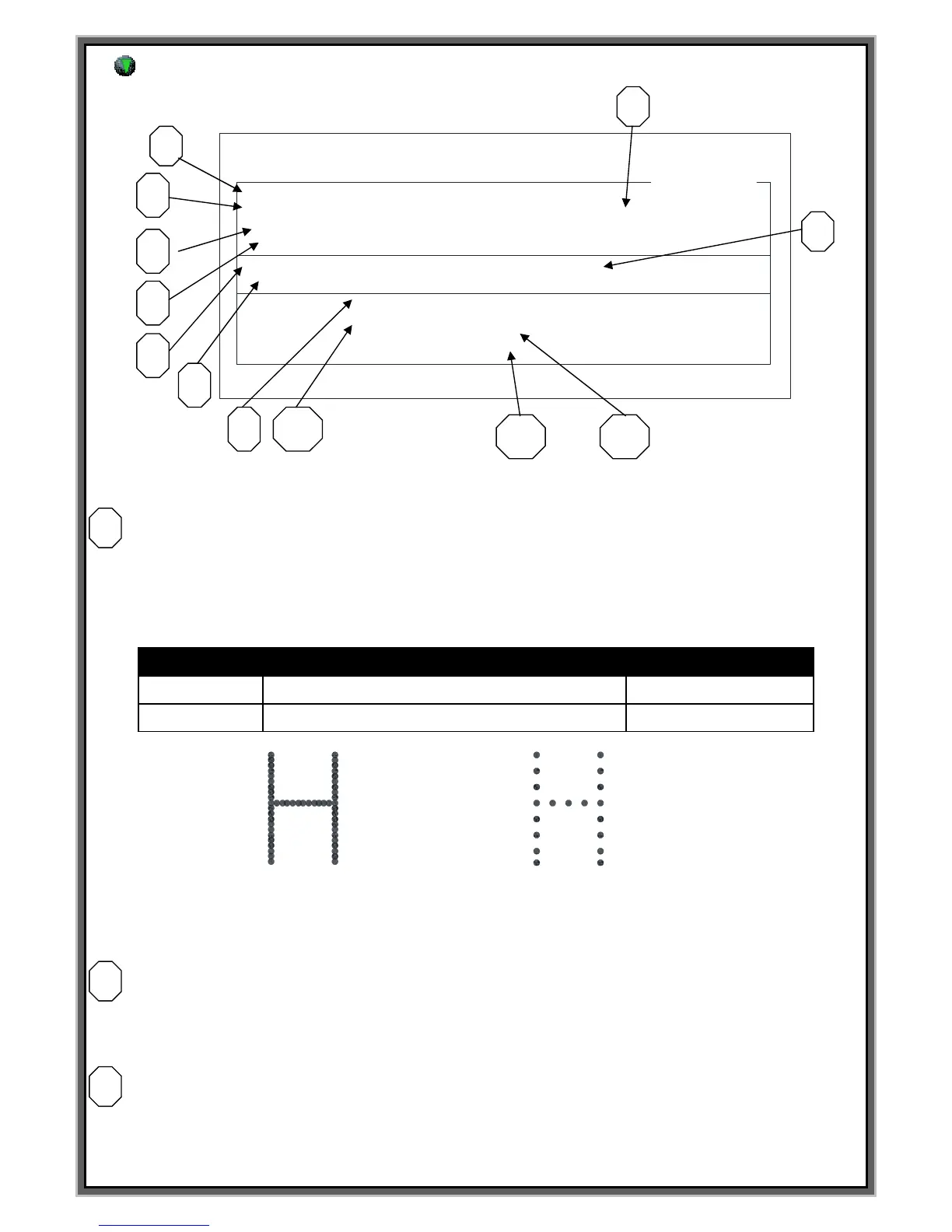

F5 ( SETUP )Screen : PARAMETER

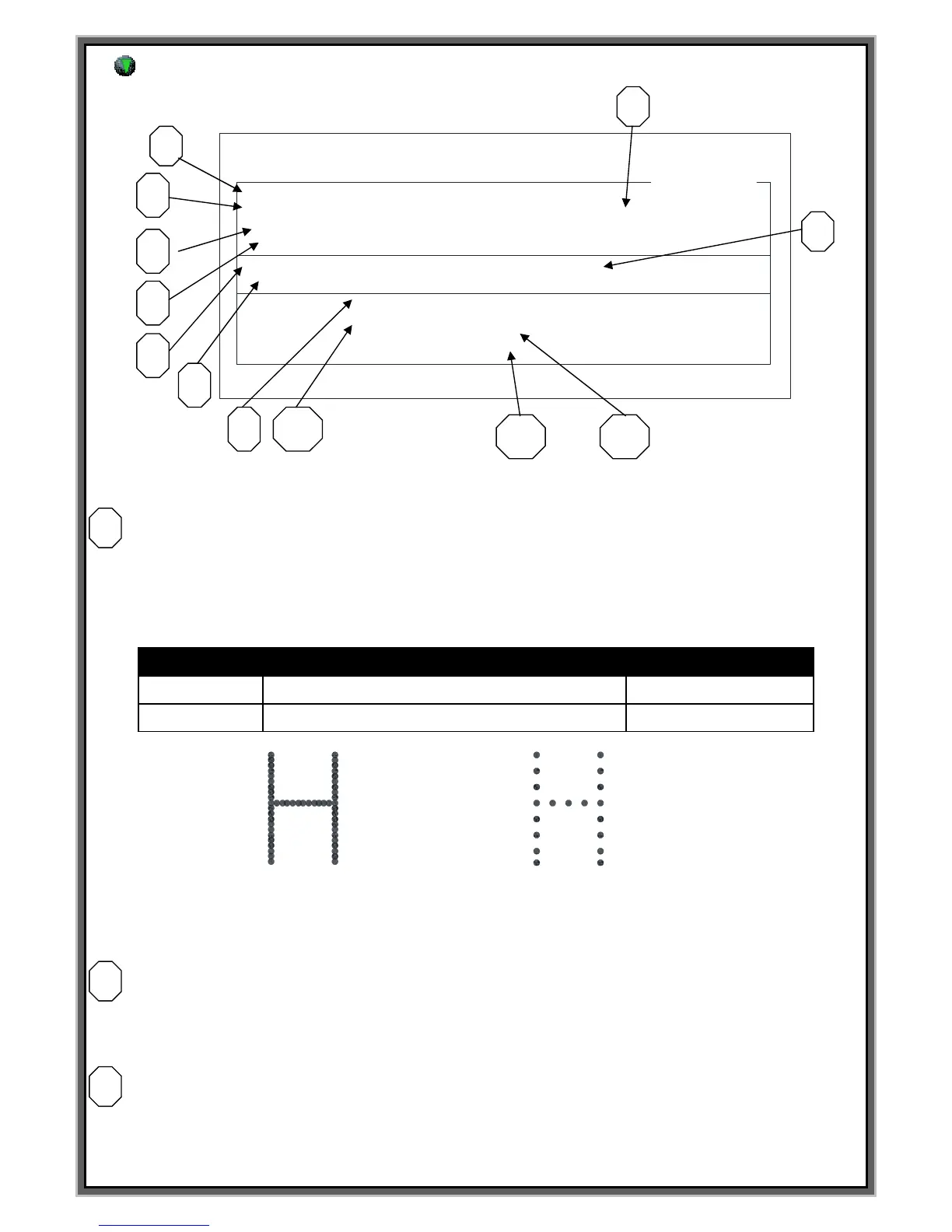

MARK SPEED : Real speed of marking pin.

In case the marking speed is too higher, distance between each dot of cha. become wider

or marking of cha. can be dented.

Refer to below chart and set up the parameter.

LP-06 , LP-10 , LP-10P LP-Series

<Normal speed> <In case the MARK SPEED is faster

as compared marking pin.>

MOVE SPEED : Moving speed except for marking

--> Default value of MOVE SPEED is [12000]. In case you set it up higher,

marking location can be changed. You had better keep this value if possible.

ACCEL. RATE : Acceleration rate of motor.

--> Default value of Acceleration rate for motor is [0100].

In case marking location is changed or moving speed of marking pin is too fast,

you can make it..

F1 : M_MENU F2 : A_MARK F3 : EDIT F4 : FILE

F5 : SETUP F6 : TEST F7 : LOAD F8 : COMM

MARK SPEED [ 02000 ]

Use PLC Sequence table ? [ Y ]

Echo mark data to host ? [ Y ]

Move X then Y to offset ? [ Y ]

Move Y then X to home ? [ Y ]

[ SETUP MODE]

CUSOR_MOVE : ENTER F5 : DATE CODE SET

MOVE SPEED [ 12000 ] ACCEL. RATE [0100 ].

X MOTOR [ 10000 ] STEPS/100MM.

Y MOTOR [ 10000 ] STEPS/100MM.

SOL. DN DLY [ 00020 ] SOL. UP DLY [ 00020 ]

END OUT DLY [ 01500 ]

Loading...

Loading...