MR 150M–1050M SINGLE – MXIII CONTROLLER

OPERATION

15

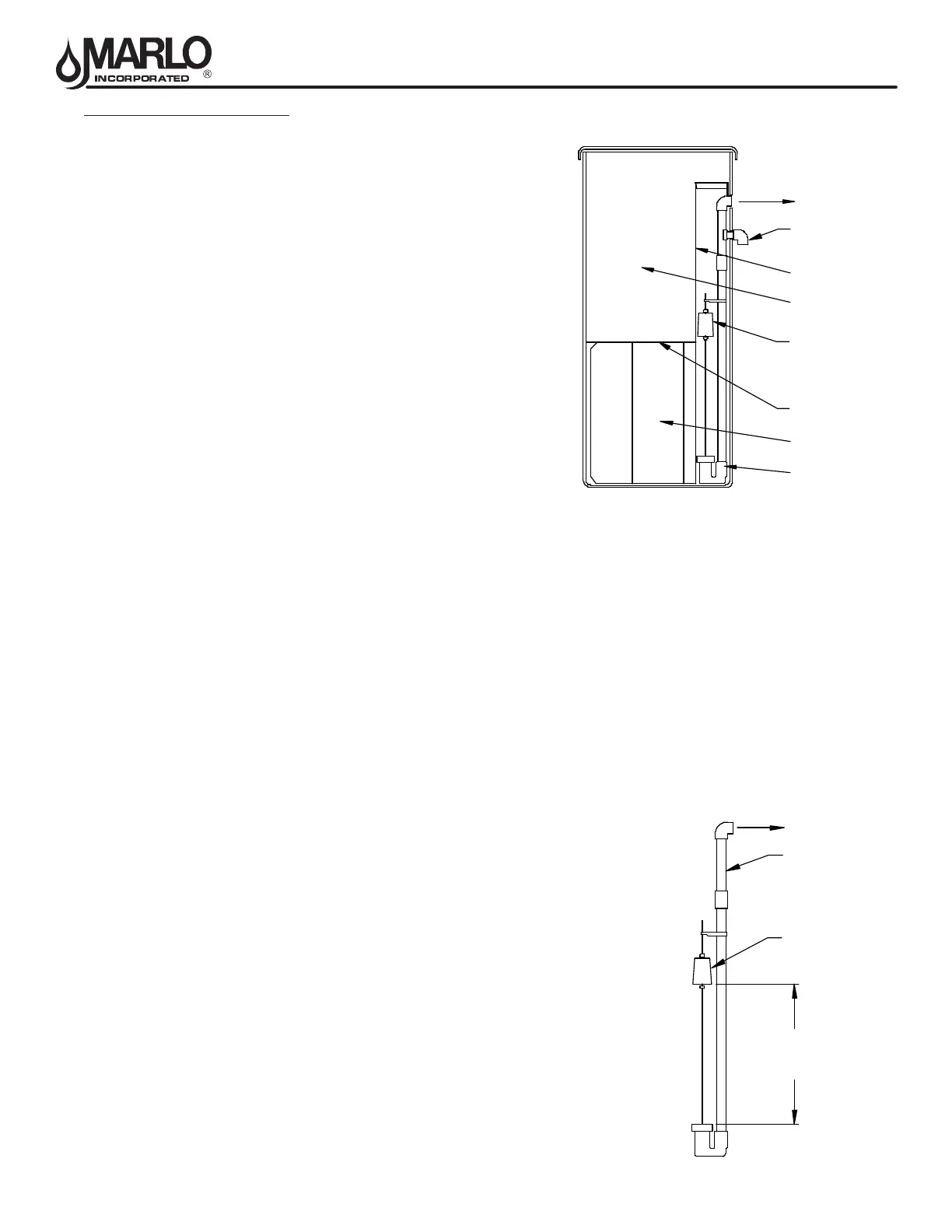

BRINE MAKER OPERATION

The brine-maker is an automatic brining system, which is easily

adjusted to provide maximum operating eciency of your water

softener. It is a combination salt storage and brine-measuring tank

complete with an automatic valve.

The brine-maker consists of:

1. An open brine tank with a platform dividing it into sections:

• The upper section is used for dry salt storage

• The lower section for brine storage.

2. An automatic brine valve which is housed in a closed tube or “well”.

After each regeneration, water ows from the brine valve and into the

brine tank. When the water level rises slightly above the platform, a

oat closes the automatic brine valve. Salt slowly dissolves to form

concentrated brine. As brine is formed, the liquid volume increases

and the level rises in the salt. The resulting level may be 2 to 10 inches

above the platform depending on the amount of salt for regeneration.

During regeneration, the brine injector creates suction, which opens

the brine valve and draws into the softener tank. When the brine level

falls below the brine valve, the valve seats and prevents air from

entering the system.

RECOMMENDED TYPES OF SALT

Only puried salt should be used in the brining system. Palletized salt (“Button”, “Nugget”, and “Pellet”) or block salt

(free binders) is recommended. Do not use granulated salt, as it will fall through the platform screen.

Rock salt is not normally recommended. Most rock salt contains sludge-forming insoluble that collect on the platform

and prevents proper salt-water contact.

Only salt containing 0.5% or less of insolubles will provide continued satisfactory operation. If, salt with more insolu-

bles is used, the brine maker will require periodic cleaning.

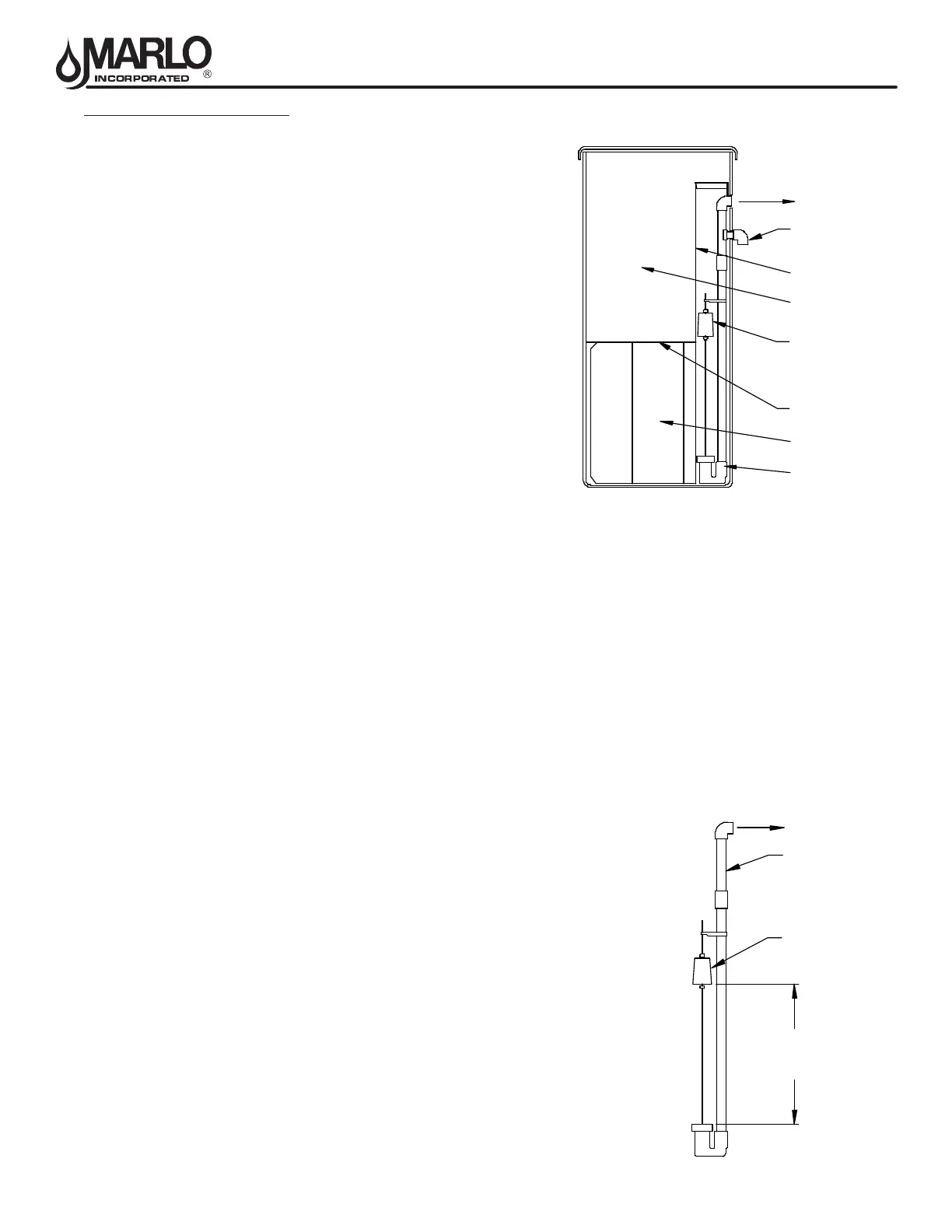

MINIMUM SALTING ADJUSTMENT

Minimum salting is the most ecient use of salt. But it does minimize the capacity of

the unit, which will decrease the time between regenerations. Only make this adjust-

ment after the unit has completed a brine tank rell step and the water level was

checked to be above the salt platform. Follow these instructions to adjust your unit to

regenerate with minimum salt usage.

• Adjust brine tank rell time to the minimum setting according to the

specication table. Refer to the “Setting the regeneration cycle timer page.

• Monitor the water daily for hardness. It may also be necessary to adjust the

regeneration frequency, since the capacity of the unit has changed.

1. Remove brine valve assembly from brine well.

2. Remove air check from assembly.

3. Shorten the riser tube by removing the top extension pipe.

4. Reassemble brine valve assembly.

5. Reinstall the assembly into the brine well. The assembly will no longer reach the

bottom of the brine tank.

TO INJECTOR

OVERFLOW

(PIPE TO DRAIN)

FLOAT

BRINE VALVE

LIQUID BRINE

DRY SALT

STORAGE

SALT SHELF

BRINE WELL

TO INJECTOR

TOP

EXTENSION

BRINE VALVE

FLOAT HEIGHT

FLOAT

Loading...

Loading...