32 33

model no. 055-6751-6 | contact us 1-800-689-9928

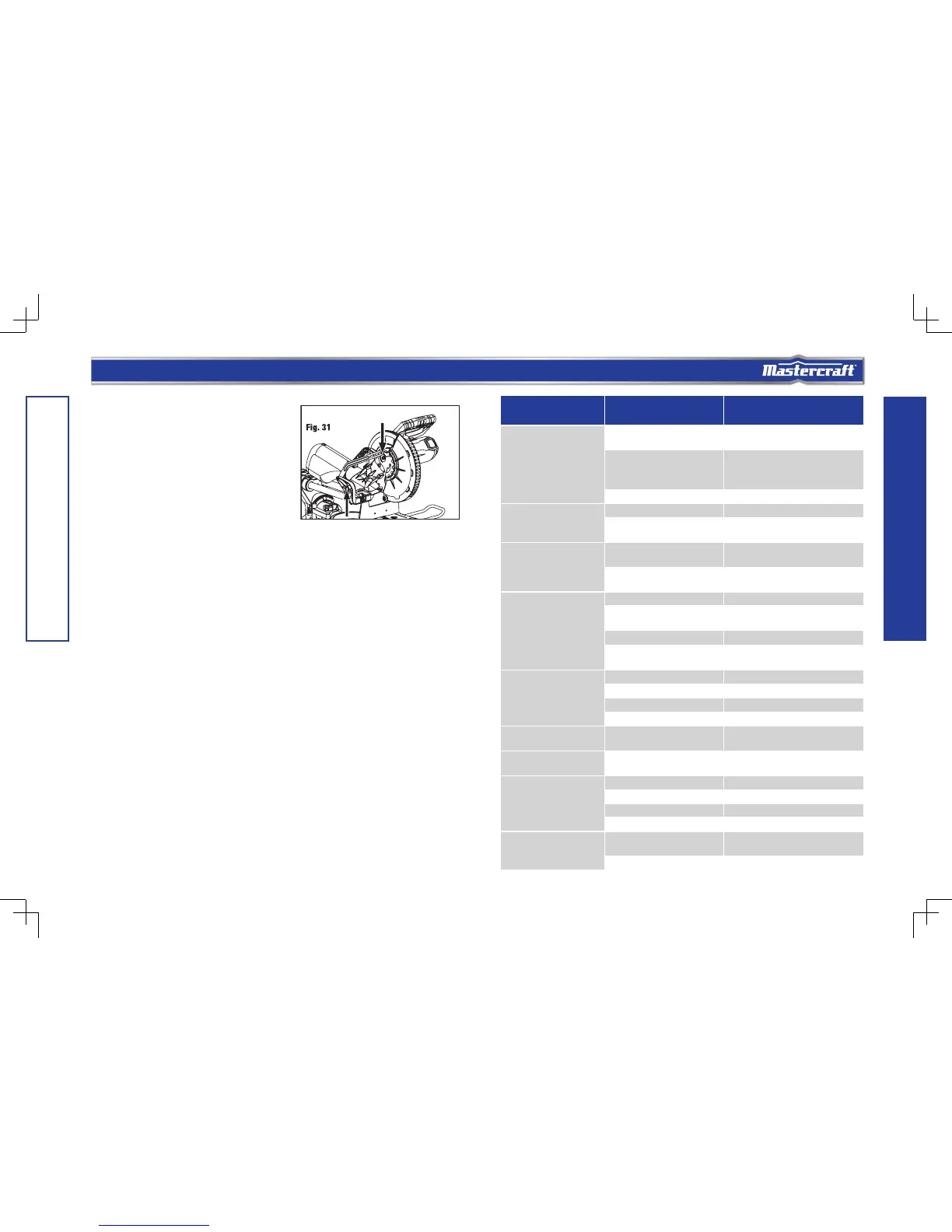

LUBRICATION

All the motor bearings in this tool are lubricated with a

sufcient amount of high-grade lubricant for the life of the

unit under normal operating conditions; therefore, no further

lubrication is required.

Lubricate the following as necessary:

Chop pivot: Apply light machine oil to points indicated in

illustration.

Central pivot of plastic guard: Use light household oil (sewing

machine oil) on metal-to-metal or metal-to-plastic guard

contact areas as required for smooth, quiet operation. Avoid excessive oil as sawdust will cling to it.

MAINTENANCE

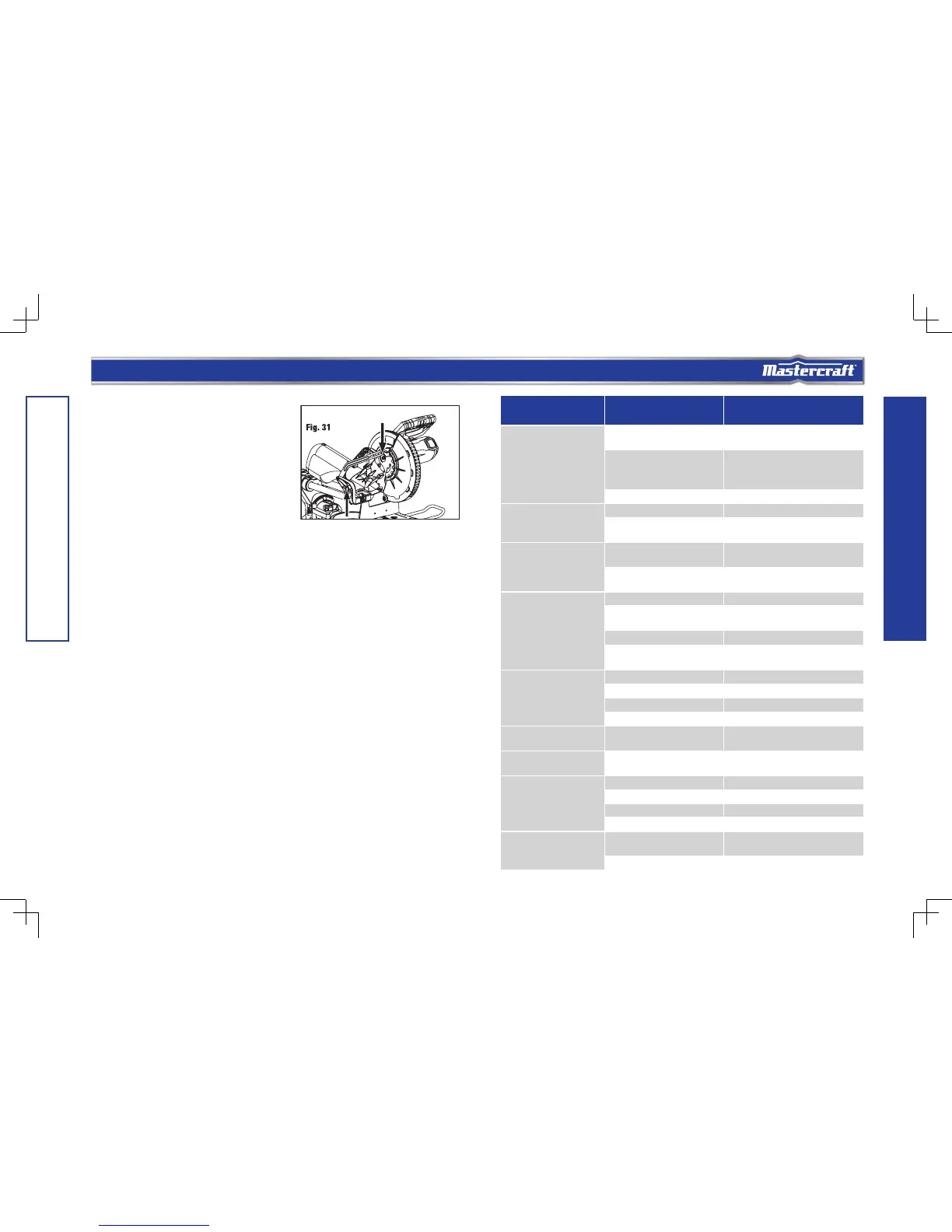

TROUBLESHOOTING

Brake does not stop blade

within 10 seconds

Motor brushes not sealed or

lightly sticking

Inspect/clean/replace brushes

Motor brake overheated from use

of defective or wrong size blade

or rapid ON/OFF cycling

Use a recommended blade

Arbor bolt is loose Retighten

Motor does not start

Brush worn Replace brushes

Power source fuse or time delay

fuse

Check time delay fuse or circuit breaker

Angle of cut inaccurate

Mitre table unlocked

Rotate the mitre locking handle all the

way to the right

Too much sawdust under table

Vacuum or blow out dust while wearing

eye protection

Head assembly cannot fully

raise or blade guard cannot

fully close

Parts failure Contact service centre

Pivot spring not replaced properly

after service

Contact service centre

Sawdust build-up Clean and lubricate moving parts

Lock-down pin not set properly

Check, adjust and properly set saw-

head locking pin

Blade binds, jams or burns

wood

Improper operation See OPERATING INSTRUCTIONS section

Dull blade Replace or sharpen blade

Improper blade Replace blade

Warped blade Replace blade

Blade hits table Misalignment

See “Assembly and adjustments” sec-

tion

Brush sparks excessively

when switch is released

Brush worn/damaged Replace brushes

Saw vibrates or shakes

Saw blade damaged Replace blade

Saw blade loose Tighten black bolt

Saw not properly fastened down Fasten saw to stand, bench or table

Workpiece not properly supported

Properly support or clamp workpiece

Laser line projection is hard

to see

Light in work area is too bright

Move the mitre saw to work area with

proper light

Saw dust on the laser lens Clean laser lens with a soft, dry brush

Loading...

Loading...