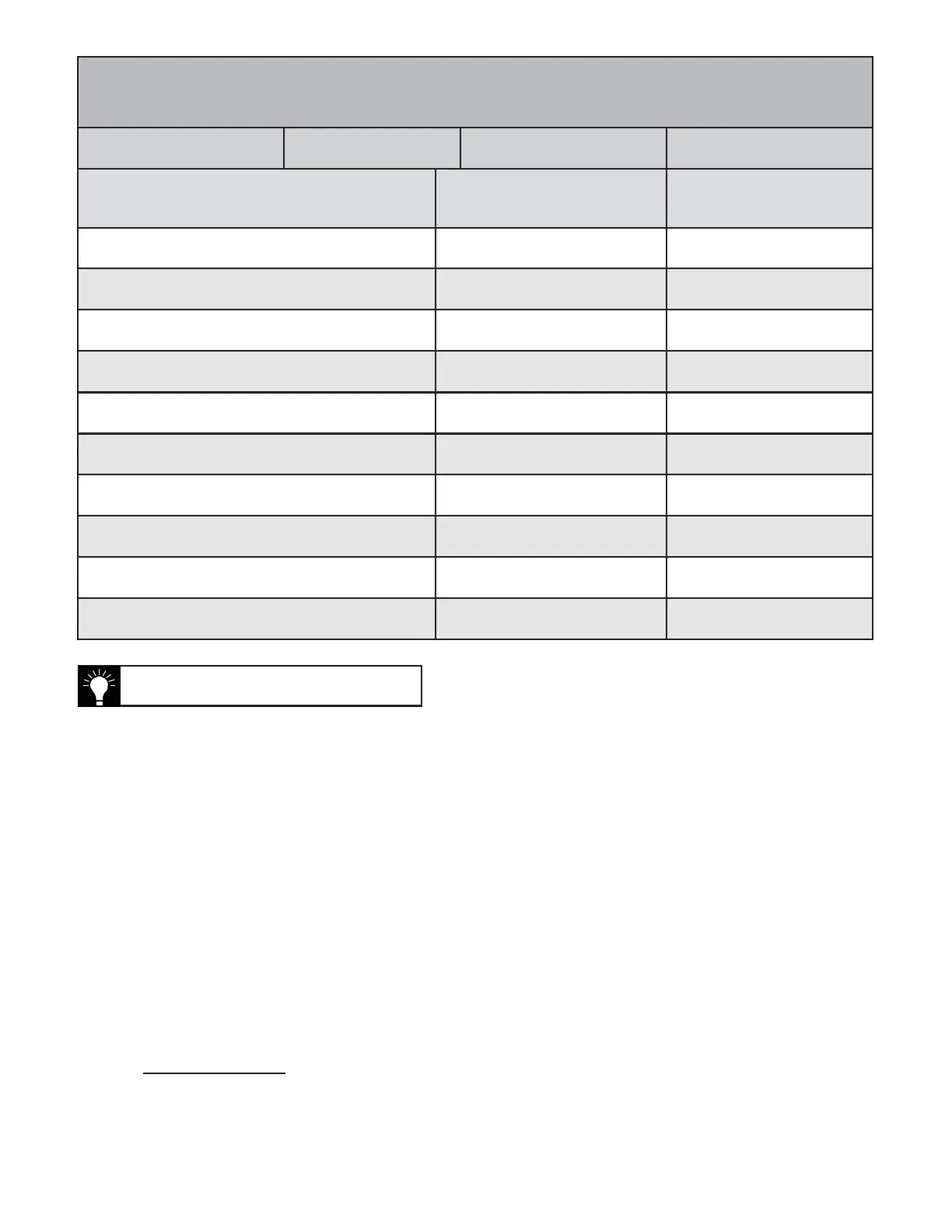

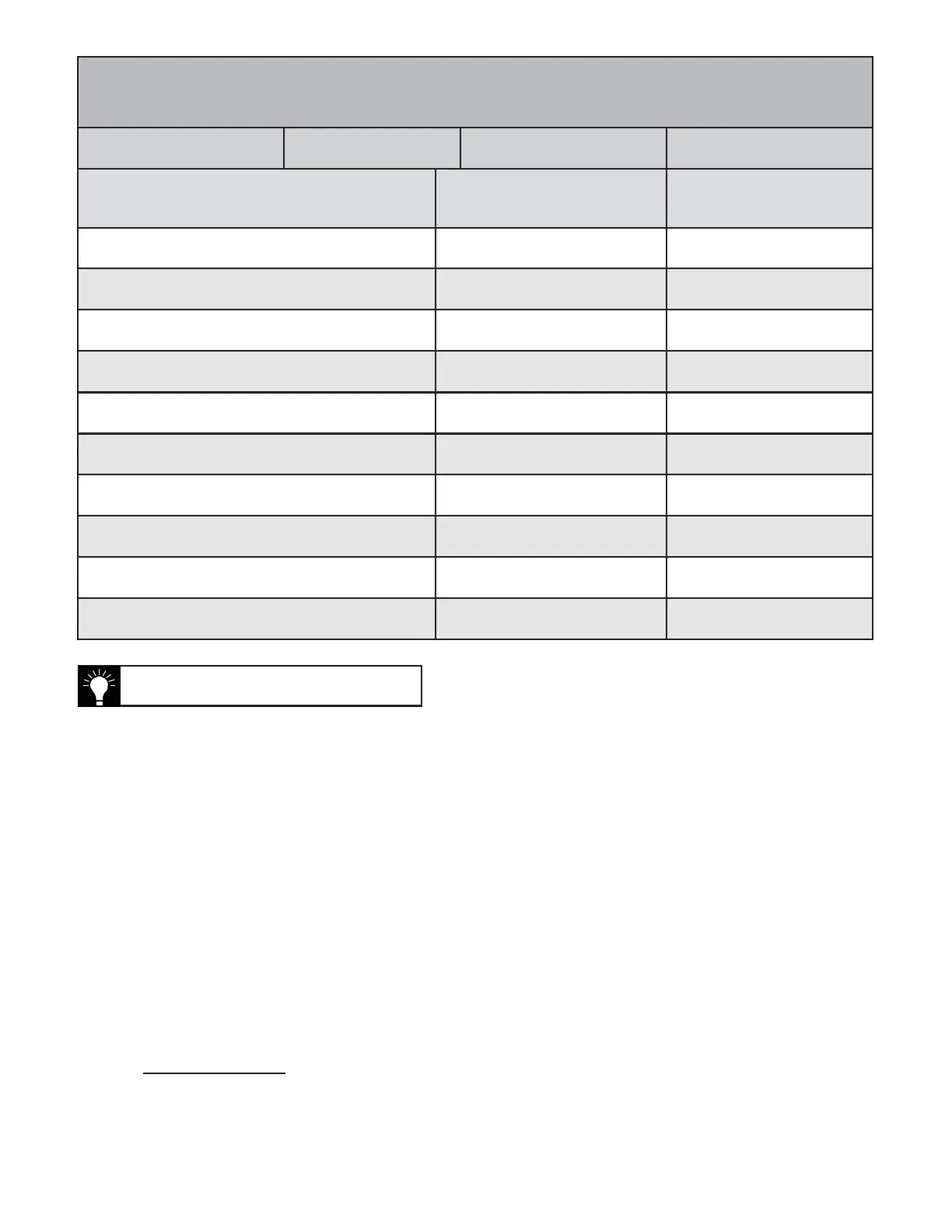

APPENDIX: Operating Standard form

1 BURNER IRONER

Model: Serial #:

Date:

/ /

Approved by:

FLATWORK / FABRIC CONTENT TEMPERATURE SETTING OPERATING SPEED

/

/

/

/

/

/

/

/

/

/

Tip - Flatwork

Warm Rinse

A warm rinse allows more water to be extracted from the material. This means the ironer needs to

remove less moisture from the flatwork to produce a dry, high quality nish. Furthermore, the ironer can be

run faster if the nal rinse is warm.

Moisture Retention (MR)

After extraction, the optimum MR is 30% - 35% for mixed- ber-content fabrics and 45% - 50% for cotton

fabrics. To determine the MR after extraction, use a precise scale to measure the “still wet, but extracted”

flatwork; then weigh again after the same flatwork is “completely dry”. Subtract the weight of the “still wet, but

extracted” flatwork from the “completely dry” flatwork. Divide the weight difference by the “completely dry”

flatwork weight. Finally, multiply the resulting weight by 100 to determine the MR percentage.

The optimum MR after ironing is 4% or less. Ironing is not intended to remove 100% of the moisture

from the flatwork. Therefore, feel the flatwork when it rst comes out of the unit; there should be a slight

moisture content. Allow the flatwork to sit for a few minutes to allow excess steam and heat to dissipate in the

air. Check the flatwork again; it should now feel dry to the touch. For more information, review the Instruction

Manual, Flatwork Handling procedure.

NOTE:

This Operating Standard form needs to be completed and approved by the laundry manager at each facility. Each laundry facility

uses different means to accomplish a quality nish, including wash formulas, extraction, number of personnel, etc.; the Chicago Dryer

Company does not assume any responsibility how this form is completed or used.

Loading...

Loading...