Comet Executive Gas Preventive Maintenance

4-1

Chapter 4

PREVENTIVE MAINTENANCE

Various components of the Comet Executive™ Gas require scheduled attention to ensure long life

and trouble-free operation. The Preventive Maintenance (PM) Schedule below and on the next page

outlines all of the PM tasks required at regular intervals. All tasks are the responsibility of maintenance

personnel unless otherwise indicated.

Since operators run the machines, they should be trained on site to visually inspect common areas daily

and notify maintenance personnel when problems are found, such as worn or broken ribbons. All PM

intervals are based on 8-hour/day operation. Increase the PM frequency for two- or three-shift operations.

Preventive maintenance should only be done when the power is turned OFF at the main disconnect

switch. Specic preventive maintenance that requires the unit to be running should be done with extreme

caution and attention to detail.

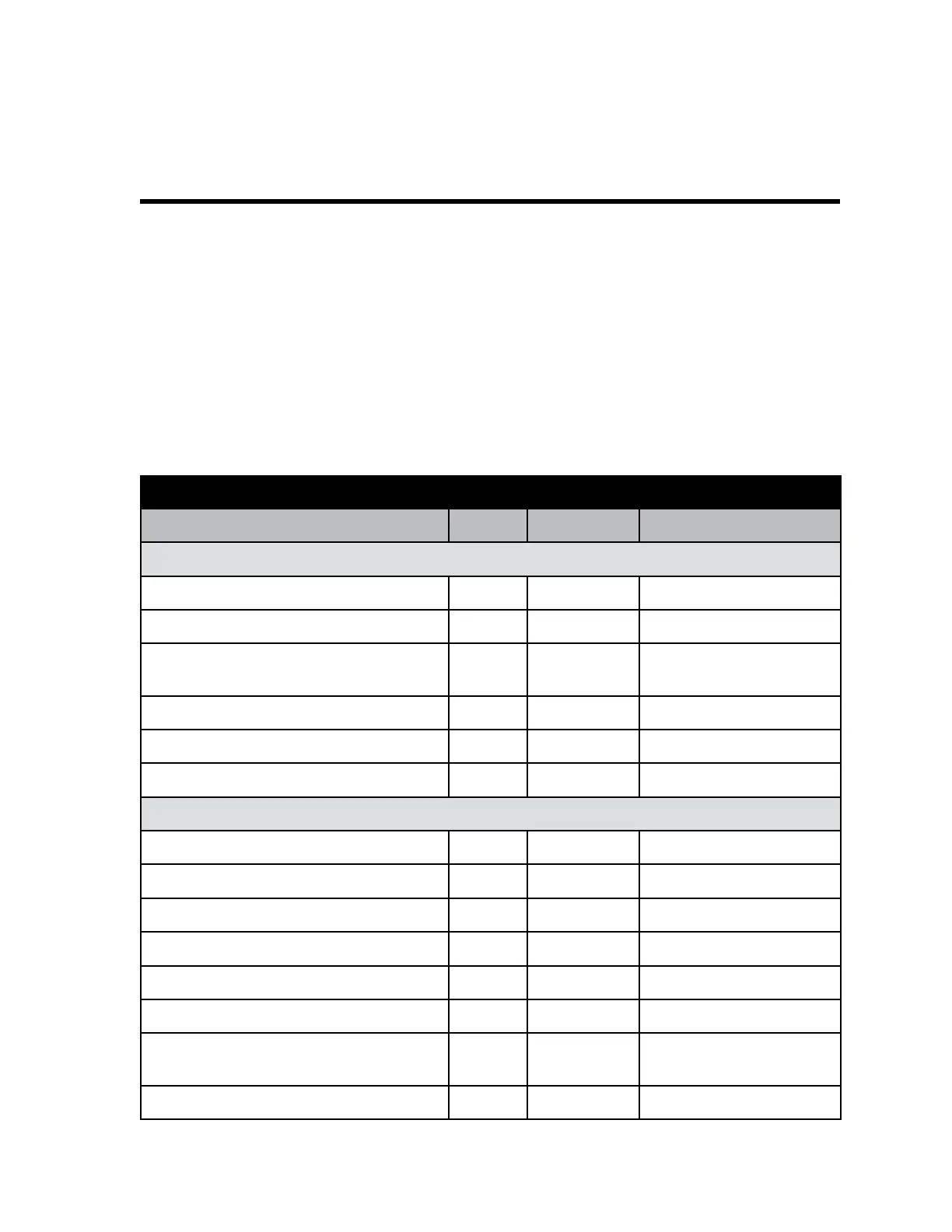

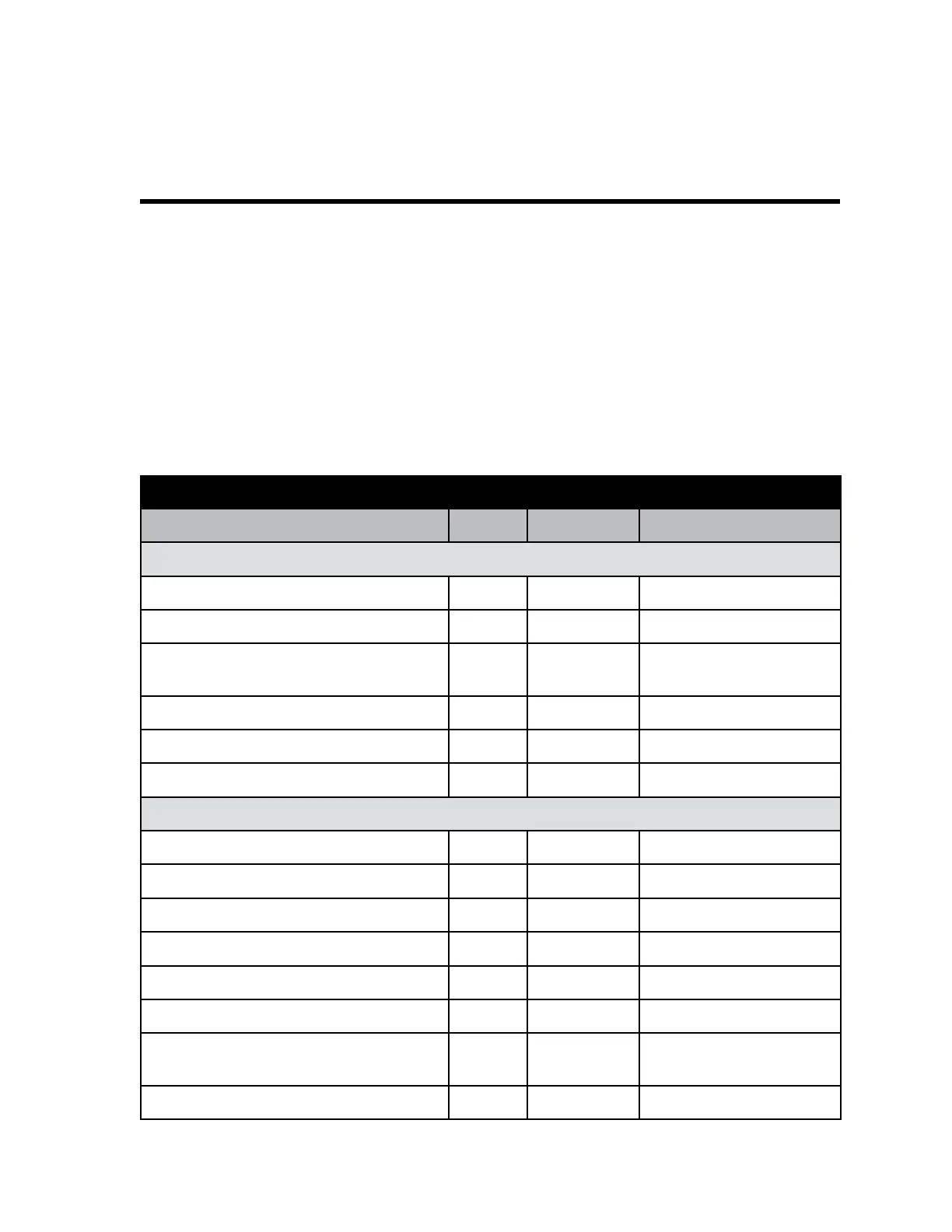

PM Task Tables

Daily, Weekly Tasks

Preventive Maintenance Schedule beginning

FREQUENCY OF TASKS BASED ON HOURS OF OPERATION

Preventive Maintenance Tasks Operator Maintenance Ironer Condition

4.1 Daily (8 Hours)

Watch and Listen for Anything Abnormal X Running/Hot

General Cleanliness X O/Disconnect Power/Cool

Check and Clean Temperature Sensor

Contact Shoes

X O/Disconnect Power/Cool

Check Guide Tapes X O/Disconnect Power/Cool

Check Safety Equipment X X Running/Cool

Wax Ironing Cylinder X Running/Hot

4.2 Weekly (50 hours)

Clean Behind Service Panels X O/Disconnect Power/Cool

Check Ironing Cylinder X O/Disconnect Power/Cool

Check and Clean Inverter X O/Disconnect Power/Cool

Grease “Weekly” Bearings X O/Disconnect Power/Cool

Oil Roll Bearing Pivots X O/Disconnect Power/Cool

Check and Clean Motors X O/Disconnect Power/Cool

Check and Clean Sail Switch and Exhaust

Blower Wheel

X O/Disconnect Power/Cool

Check Ribbon Condition and Tension X Running/Cool

Loading...

Loading...