IM-738 Page 79

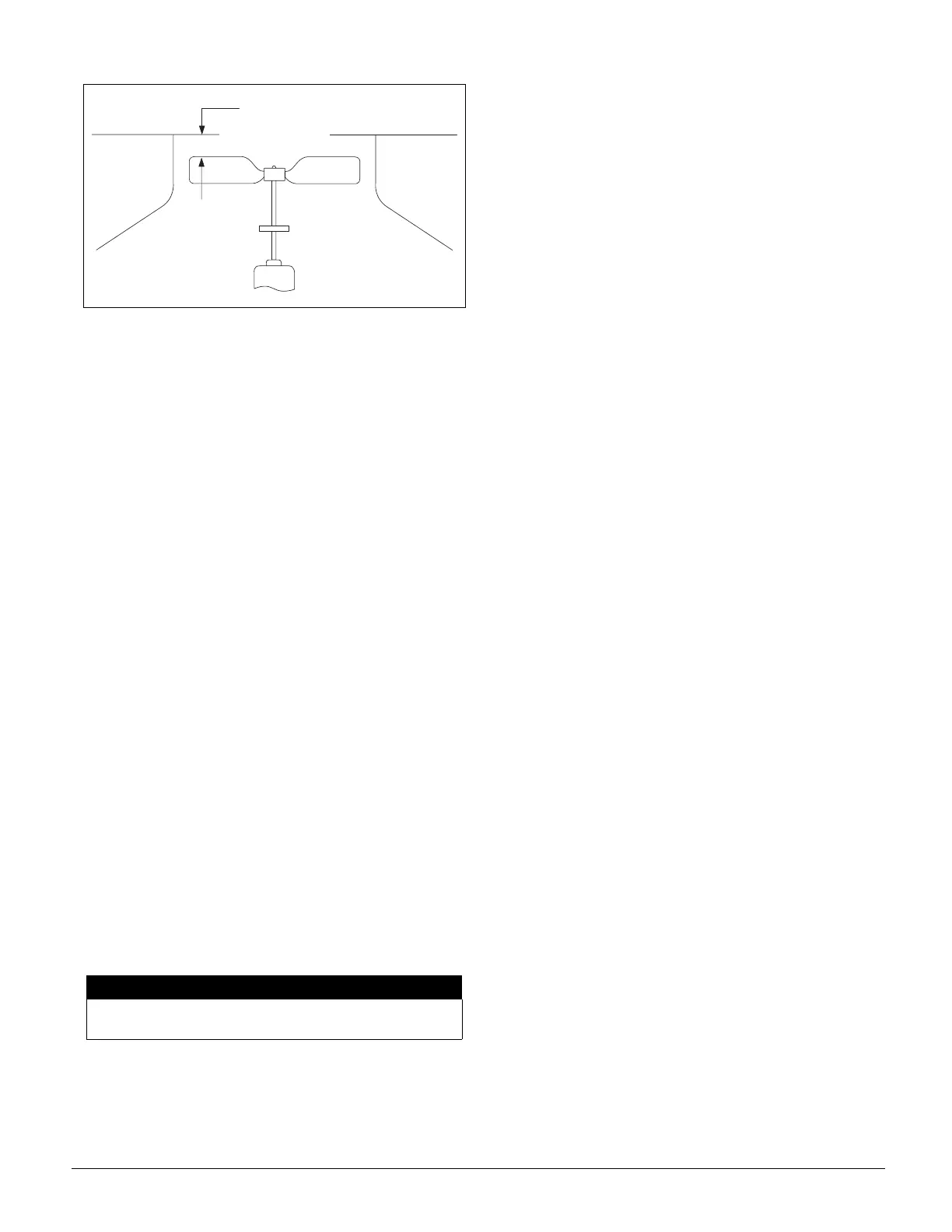

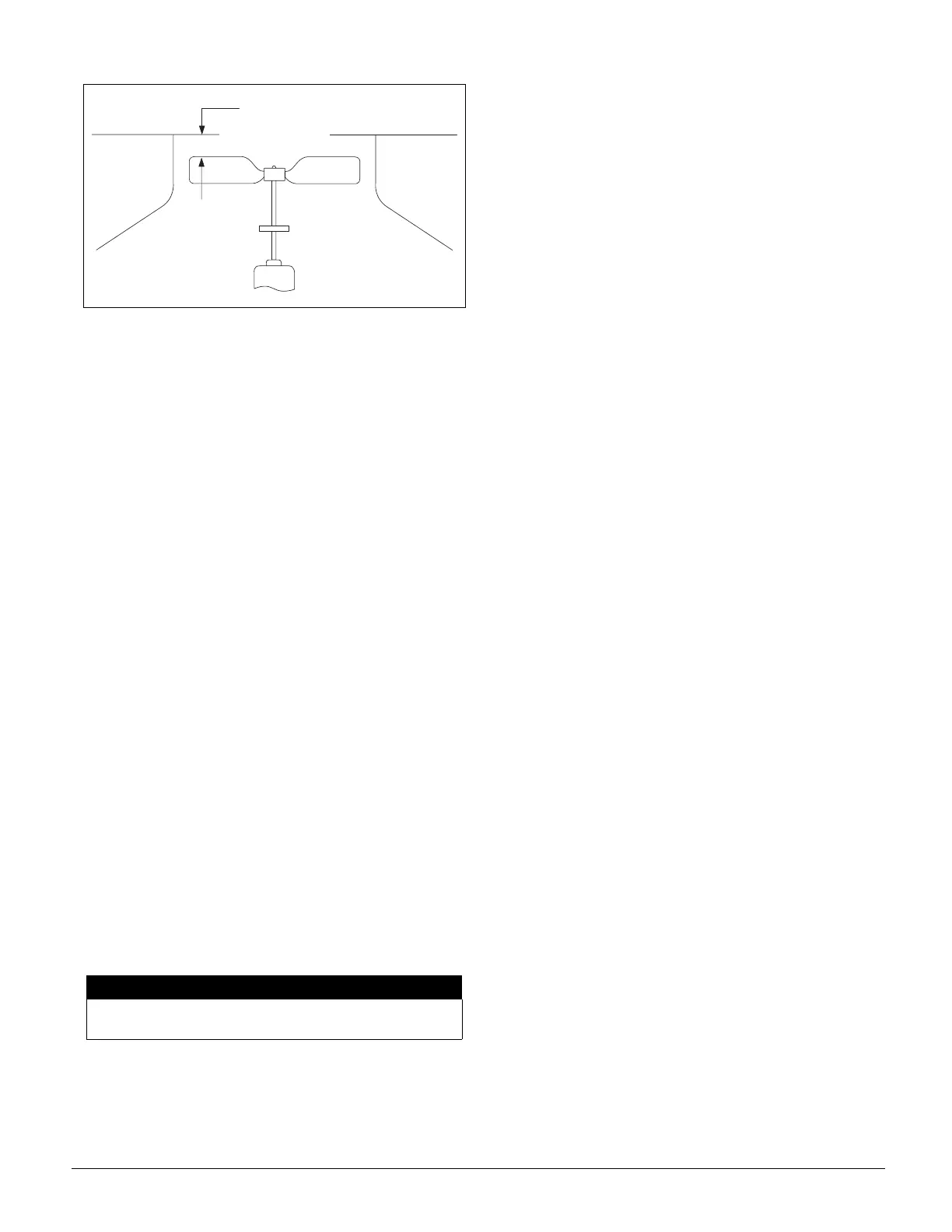

Figure 85. Condenser Fan Blade Positioning

Perform the following procedure:

1. At the keypad, set the cooling setpoints low enough so

that the controller will call for multiple stages of mechani-

cal cooling. On CAV-ZTC units, adjust the "Cooling

Spt=" entry on menu item 12C. On VAV or CAV-DTC

units, adjust the "Cooling Spt=" entry on menu item 12B

and the "Setpoint=" entry on menu item 13A.

2. Place the unit into the "0cc-Cool Only" mode through

keypad menu 11 ("Control Mode").

3. Verify that the low ambient compressor lockout tempera-

ture, "Min OAT=" (menu item 13B), is set below the out-

door air temperature.

Note: Do not attempt to operate the compressors if the

outdoor air is too cool. See the warning statement under

“Compressor Start-up” on page 78.

4. Turn pumpdown switch PS3 to "on."

5. Turn compressor control circuit switch CS1 and pump-

down switch PS1 to "on."

Now refrigeration circuit #1 is enabled and circuit #2 is

disabled. After CS1 is closed, time delay relay TD1 starts

its 5-minute timing cycle. Note that if the unit has an

economizer and the outdoor air enthalpy is low, the econo-

mizer must fully open before the controller will energize

mechanical cooling. When the outdoor air damper has

fully opened and the TD1 timer has expired, liquid line

solenoid valve SV1 should open. If the solenoid valve

does not open, do the following:

a. Verify that there is a call for cooling by checking the

display on menu 1, "Unit Status."

b. Verify that the oil safety control is not tripped. If it is, it

must be manually reset.

c. Trace the circuits.

6. Verify that compressor #1 starts. On units without optional

low ambient start, the compressor should start shortly after

the solenoid valve opens. On units with low ambient start,

the compressor should start when the solenoid valve opens.

If the compressor motor hums but does not run, verify that

it is getting three-phase power.

The compressor should operate continuously while there is

a call for cooling. If the compressor stops because the oil

pressure switch trips, see "Oil Pressure" below. If the

compressor cycles on its low pressure switch, do the fol-

lowing:

a. Verify that the circuit is not short of refrigerant.

b. Check for low airflow.

c. Check for clogged filters.

d. Check for restricted ductwork.

e. Check for very low temperature return air entering

the unit.

f. Verify that the liquid line components, expansion valve,

and distributor tubes are feeding the evaporator coil.

g. Verify that all air handling section panels are closed.

h. Verify that the suction service valve and the liquid line

service valves are completely open.

7. Verify that the compressor stages properly. When com-

pressor #1 starts, the unloaders (if any) should be ener-

gized. As the controller stages and further loads the

compressor, it de-energizes the unloaders. For more infor-

mation on staging sequences, see the "Controller Outputs"

section of Bulletin No. IM 483, "MicroTech II Applied

Rooftop Unit Controller."

8. Verify that the condenser fans are cycling and rotating

properly (blowing air upward). When the compressor

starts, at least one condenser fan should also start. The

FanTrol pressure and temperature switches should cycle

the remaining fans as required to maintain the refrigerant

head pressure. Refer to the unit wiring diagrams and to

“Condenser Fan Arrangement” on page 6.

9. Check the oil level in the compressor sightglass. See "Oil

Pressure" below. If a low oil level and heavy foaming is

observed in the compressor sightglass, it is possible that

excess liquid refrigerant is returning to the compressor.

Check the suction superheat, see “Checking Superheat”

on page 80; it should be between 10°F (-12°C) and 13°F

(-11°C). See “Expansion Valve Superheat Adjustment” .

10.Close solenoid valve SV1 by turning switch PS1 to "Off."

The circuit should pump down and then the compressor(s)

should stop. Place the unit into the "Occ-Fan Only" mode

through keypad menu 11.

11.Check refrigerant circuit #2 by repeating steps 2 through 10,

substituting circuit #2 component nomenclature for circuit

#1 nomenclature (CS2, PS2, TD2, SV2, compressor #2).

Note: The unit is wired for continuous, recycling pump-

down. If switches CS1 and CS2 are closed, the compressor

will start and pump down again whenever the low pressure

switch closes. Small leakages through the compressor

valves and liquid line solenoid valves can cause the circuit

to pump down periodically during the off cycles. This is

usually normal. If a compressor pumps down more than

once every 15 minutes during an off cycle, the unit should

be serviced.

12.Verify the condenser refrigerant subcooling at full capac-

ity is between 12-16°F.

NOTICE

Venting refrigerant to atmosphere is not allowed per

most local laws and/or codes.

2 . 2 5 "

Loading...

Loading...