IM-738 Page 39

Steam Coil Piping

Steam coils are provided without valves for field piping, or

piped with two-way valves and actuator motors.

The steam coil is pitched at 1/8" (3 mm) per foot (305 mm) to

provide positive condensate removal. When no factory piping

or valve is included, the coil connections are 2.5" male NPT

iron pipe.

With the factory piping and valve package, the field supply

connection is the same NPT size as the valve with female

threading (see Figure 45 on page 40).

Refer to the certified drawings for the recommended piping

entrance locations. All piping penetrations must be sealed to

prevent air and water leakage.

Note: The valve actuator spring returns to a stem up posi-

tion upon power failure. This allows full flow

through the coil.

Steam Piping Recommendations

1. Be certain that adequate piping flexibility is provided.

Stresses resulting from expansion of closely coupled pip-

ing and coil arrangement can cause serious damage.

2. Do not reduce pipe size at the coil return connection.

Carry return connection size through the dirt pocket, mak-

ing the reduction at the branch leading to the trap.

3. It is recommended that vacuum breakers be installed on

all applications to prevent retaining condensate in the coil.

Generally, the vacuum breaker is to be connected between

the coil inlet and the return main. However, if the system

has a flooded return main, the vacuum breaker should be

open to the atmosphere and the trap design should allow

venting of the large quantities of air.

4. Do not drain steam mains or takeoffs through coils. Drain

mains ahead of coils through a steam trap to the return line.

5. Do not attempt to lift condensate.

6. Pitch all supply and return steam piping down a minimum

of 1" (25 mm) per 10 feet (3 m) of direction of flow.

Steam Trap Recommendations

1. Size traps in accordance with manufacturers' recommen-

dations. Be certain that the required pressure differential

will always be available. Do not undersize.

2. Float and thermostatic or bucket traps are recommended

for low pressure steam. Use bucket traps on systems with

on-off control only.

3. Locate traps at least 12" (305 mm) below the coil return

connection.

4. Always install strainers as close as possible to the inlet

side of the trap.

5. A single tap may generally be used for coils piped in par-

allel, but an individual trap for each coil is preferred.

Steam Coil Freeze Conditions

If the air entering the steam coil is below 35°F (2°C), note the

following recommendations:

1. 5 psi (34.5 kPa) steam must be supplied to coils at all times.

2. Modulating valves are not recommended. Control should

be by means of face and bypass dampers.

3. As additional protection against freeze-up, the tap should

be installed sufficiently far below the coil to provide an

adequate hydrostatic head to ensure removal of conden-

sate during an interruption on the steam pressure. Esti-

mate 3 ft. (914 mm) for each 1 psi (7 kPa) of trap

differential required.

4. If the unit is to be operated in environments with possible

freezing temperatures, an optional freezestat is recom-

mended. See “Freeze Protection” on page 65 for addi-

tional information.

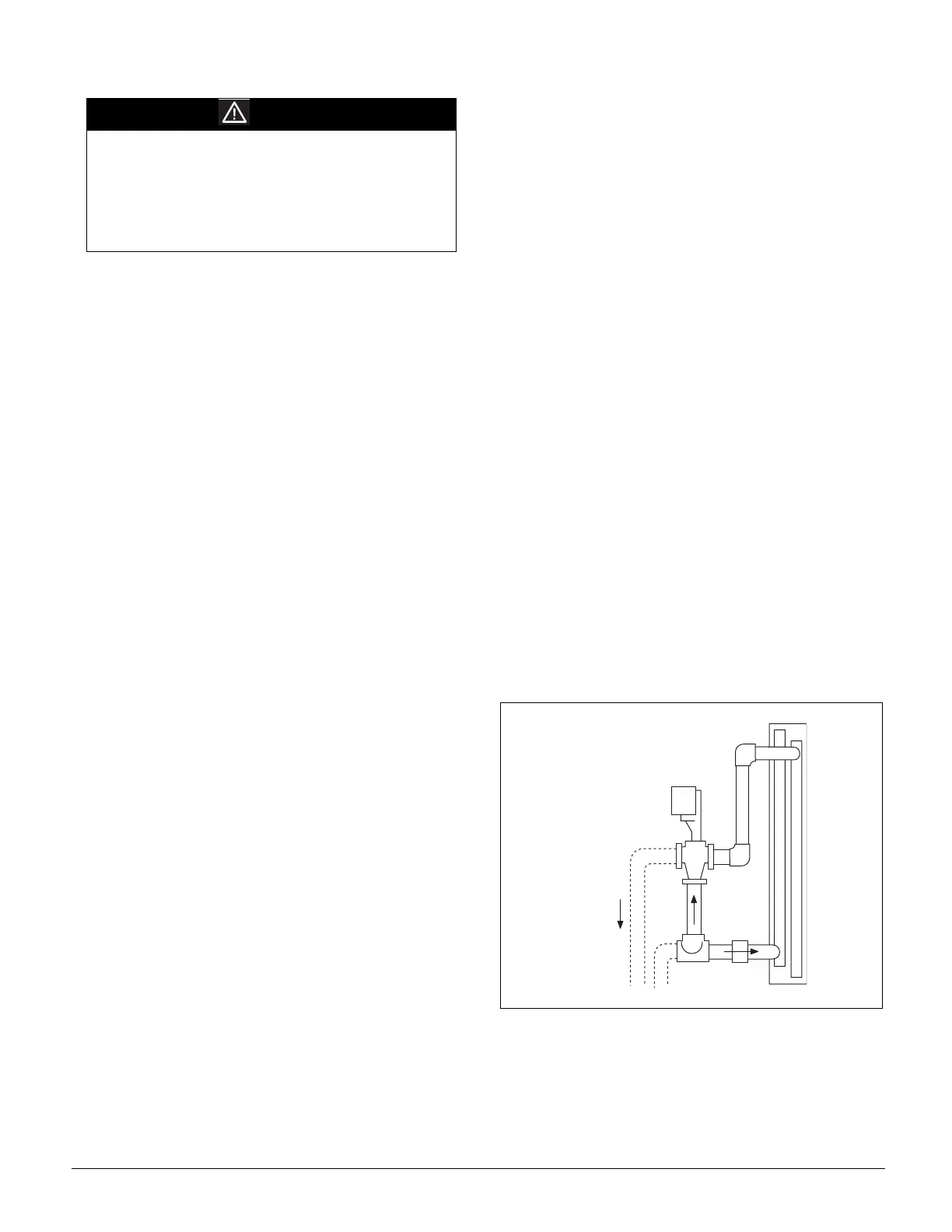

Figure 43. Hot water valve package

WARNING

Coil freeze possible. May damage equipment.

Carefully read instruction for mixing antifreeze solution

used. Some products will have higher freezing points in

their natural state than when mixed with water. The

freezing of coils is not the responsibility of McQuay

International. Refer to “Winterizing Water Coils” on

page 96.

R e t u r n

B y p a s s

S u p p l y

Loading...

Loading...