IM-738 Page 73

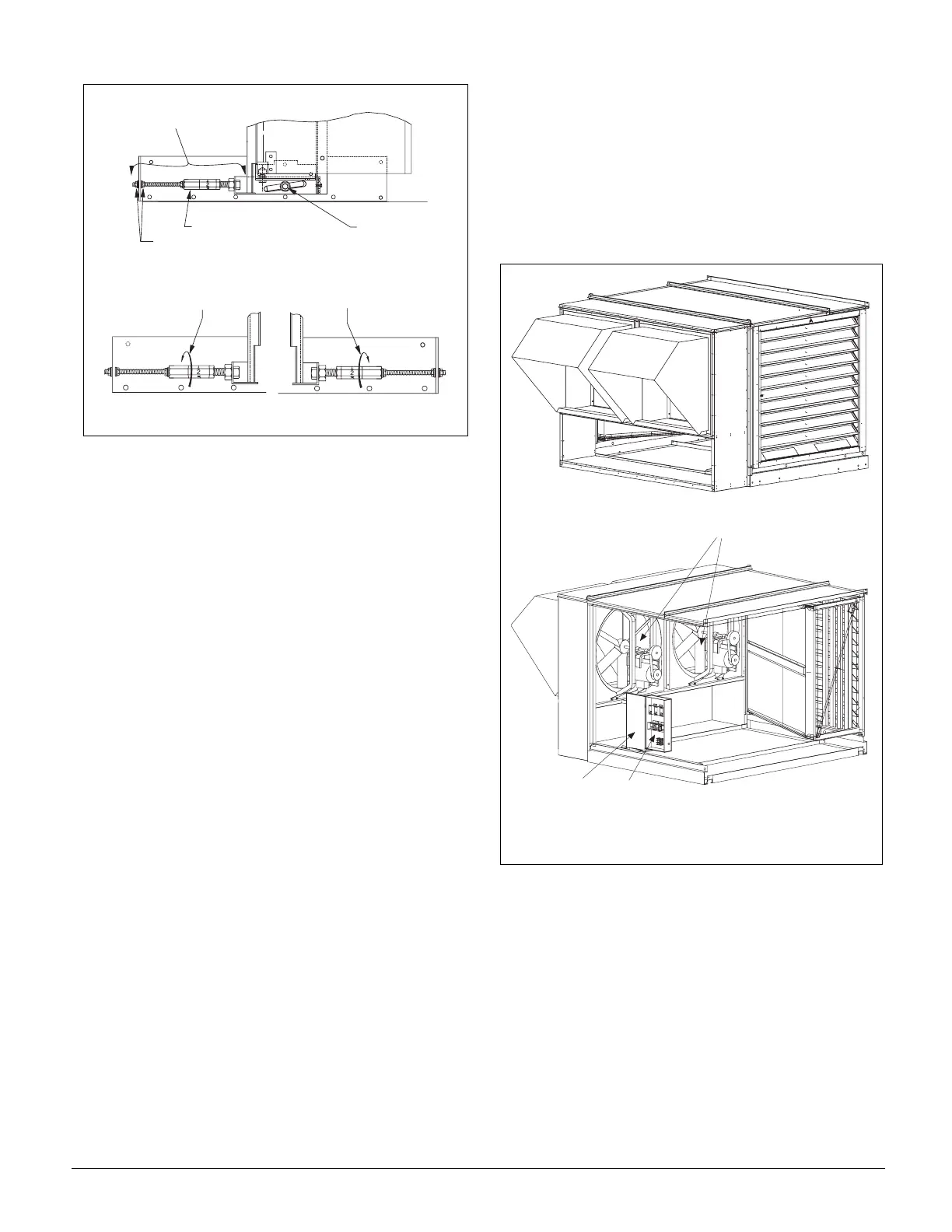

Figure 79. Leveling Adjustment

10. If the value indicated by the LH Lvl Pos=(or RH Lvl

Pos=) parameter is not within the range of 23.64 to

24.08%, a leveling adjustment is required (See Figure 79).

Leveling adjustments are accomplished by shifting the

bottom of the measuring station to the right or left. If the

LH Lvl Pos=(or RH Lvl Pos=) parameter indication is

higher than specified, the bottom of the DesignFlow

frame must be moved closer to the outdoor air damper. If

the LH Lvl Pos=(or RH Lvl Pos=) parameter indication is

lower than specified, the bottom of the DesignFlow frame

must be moved farther from the outdoor air damper.

To make an adjustment, loosen the .25-20 NC lock nut at

the slotted hole at the bottom of the frame. The threaded

adjuster facilitates small accurate movements. Reposition

the two .25-20 NC jam nuts on the threaded rod to make

large adjustments, then use the long adjuster nut to make

fine adjustments. Rotate the long adjuster nut to move the

bottom of the station. Unscrewing the long adjuster nut

from the large bolt makes the assembly longer and

reduces the LH Lvl Pos=(or RH Lvl Pos=) parameter

indication. Screwing in the long adjuster nut from the

large bolt makes the assembly shorter and increases the

LH Lvl Pos=(or RH Lvl Pos=) parameter indication.

After an adjustment is made, retighten the lock nut, gently

rap the base frame to slightly vibrate the assembly and

encourage the vane to seek its equilibrium point. Confirm

that the contact point on the fulcrum is on the vertical

mark on the damper. If the contact point is not on the ver-

tical mark, reposition the fulcrum contact point to line up

with vertical mark (Figure 78 on page 72) and take

another reading.

Important: After an adjustment is made, wait until the

LH Lvl Pos=(or RH Lvl Pos=) value on the keypad/dis-

play stabilizes before making further adjustments. This

can take several seconds.

11. After leveling, remove fulcrum and replace the access

opening covers.

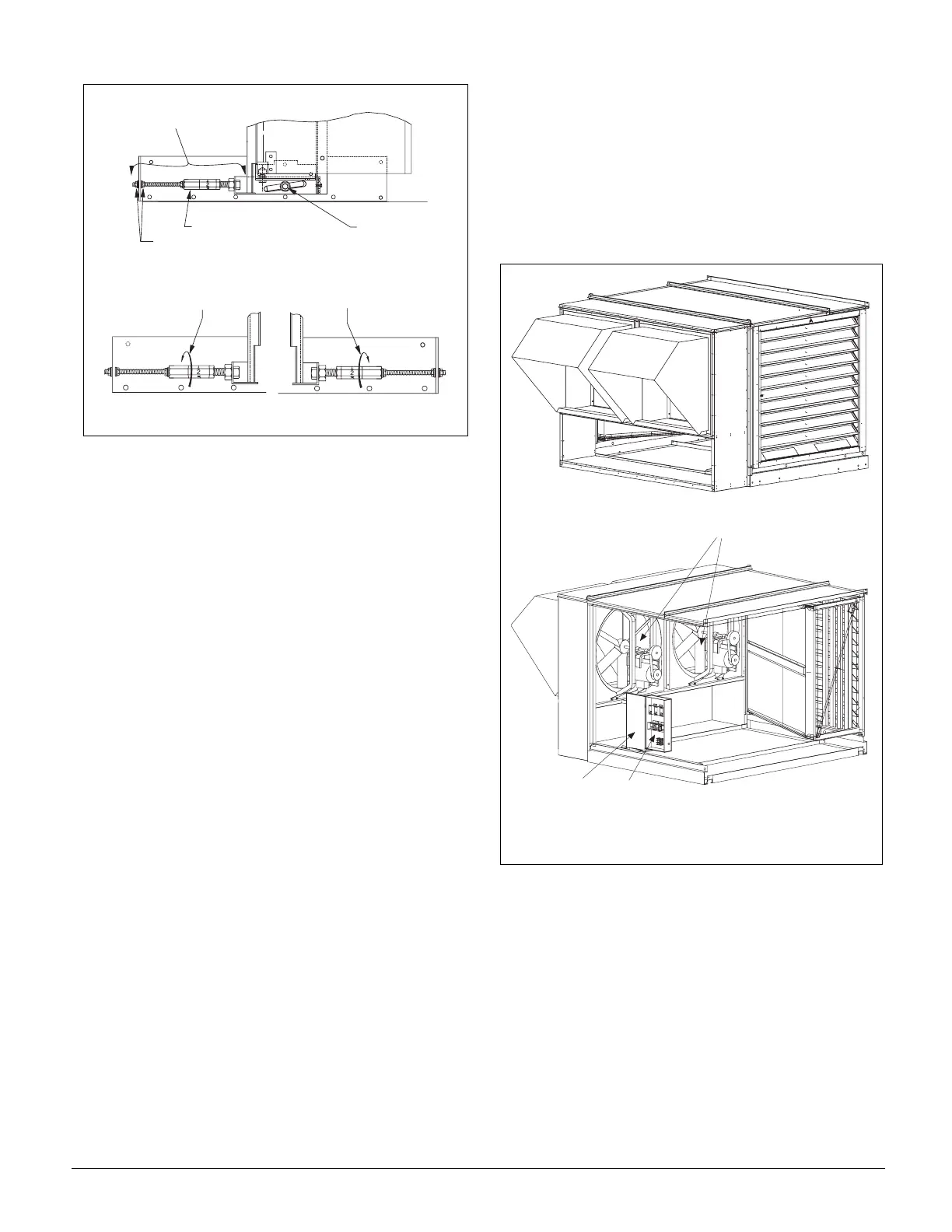

Propeller Exhaust Fan Option

Economizer units may include propeller exhaust or centrifu-

gal return fan options. This section covers maintenance and

operating instructions for the propeller exhaust option. Cen-

trifugal return fan construction, maintenance and operation is

similar to that for supply fans and covered in other sections

of this manual.

Figure 80. 2 Fans with Back Return Shown

Prestarting Checks

Check all fasteners and set screws for tightness. This is espe-

cially important for bearing set screws.

The propeller should rotate freely and not rub on the fan

panel venturi. Rotation direction of the propeller should be

checked by momentarily turning the unit on. Rotation should

be in the same direction as the rotation decal affixed to the

unit or as shown in Figure 81 on page 74. For 3-phase instal-

lations, fan rotation can be reversed by simply interchanging

any two of the three electrical leads. For single phase instal-

lations follow the wiring diagram located on the motor.

The adjustable motor pulley is preset at the factory for the

specified fan RPM. Fan speed can be increased by closing or

decreased by opening the adjustable pulley. Two or three

R I G H T H A N D A D J U S T E R

L E F T H A N D A D J U S T E R

T h r e a d e d A d j u s t e r

A s s e m b l y

J a m N u t s

L o n g A d j u s t e r N u t

L o c k n u t

T o I n c r e a s e L e v e l

P o s i t i o n R e a d i n g

T o R e d u c e L e v e l

P o s i t i o n R e a d i n g

F a n a n d M o t o r A s s e m b l i e s

V F D

S t a r t e r s

Loading...

Loading...