Page 74 IM-738

groove variable pitch pulleys must be adjusted an equal num-

ber of turns open. Any increase in fan speed represents a sub-

stantial increase in horsepower required from the motor.

Always check motor load amperage and compare to name

plate rating when changing fan speed.

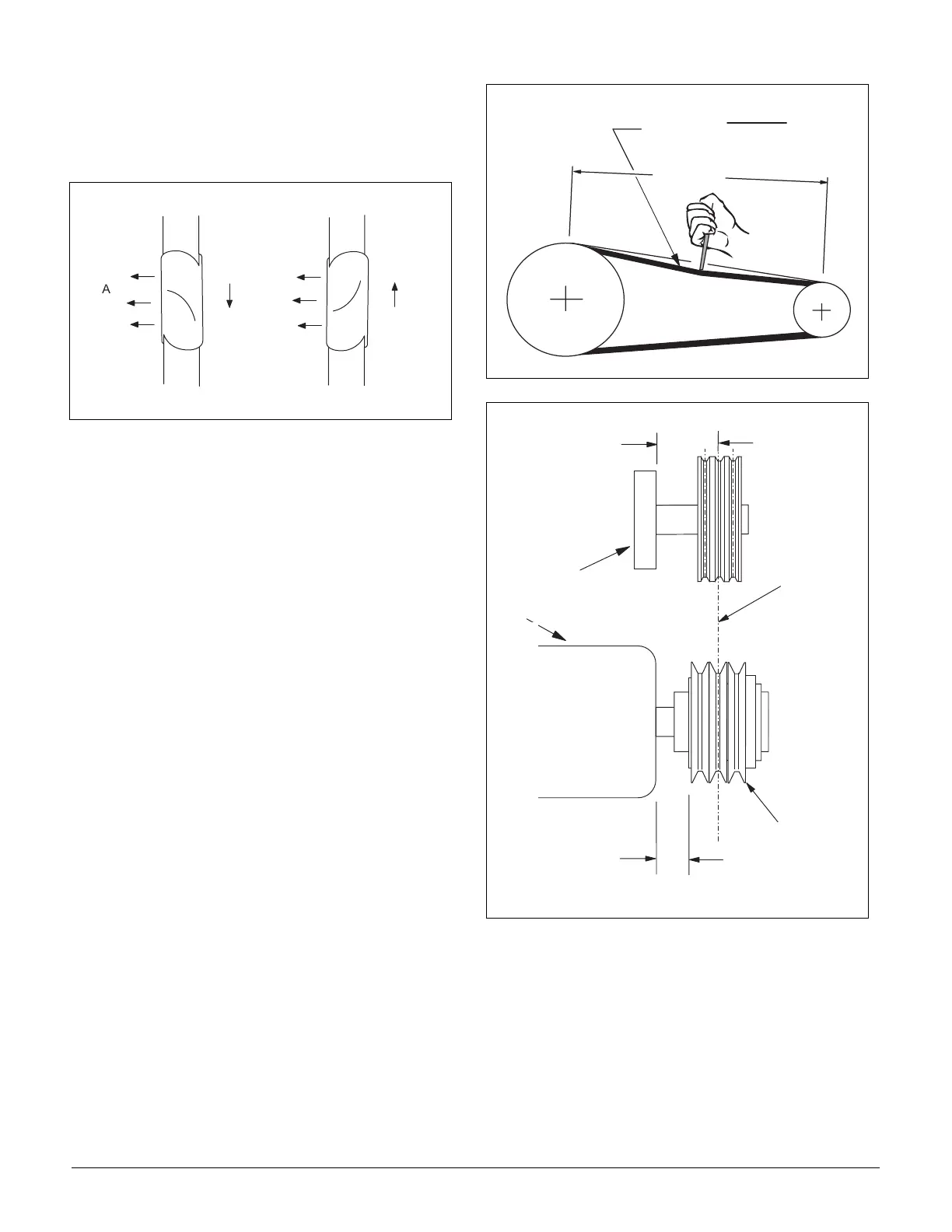

Figure 81. Fan Rotation

Once the fan has been put into operation, a periodic maintenance

program should be set up to preserve the reliability and perfor-

mance of the fan. Items to be included in this program are:

• Belts

• Bearings

•Fasteners

•Setscrews

• Lubrication

• Removal of Dust/Dirt

Belts

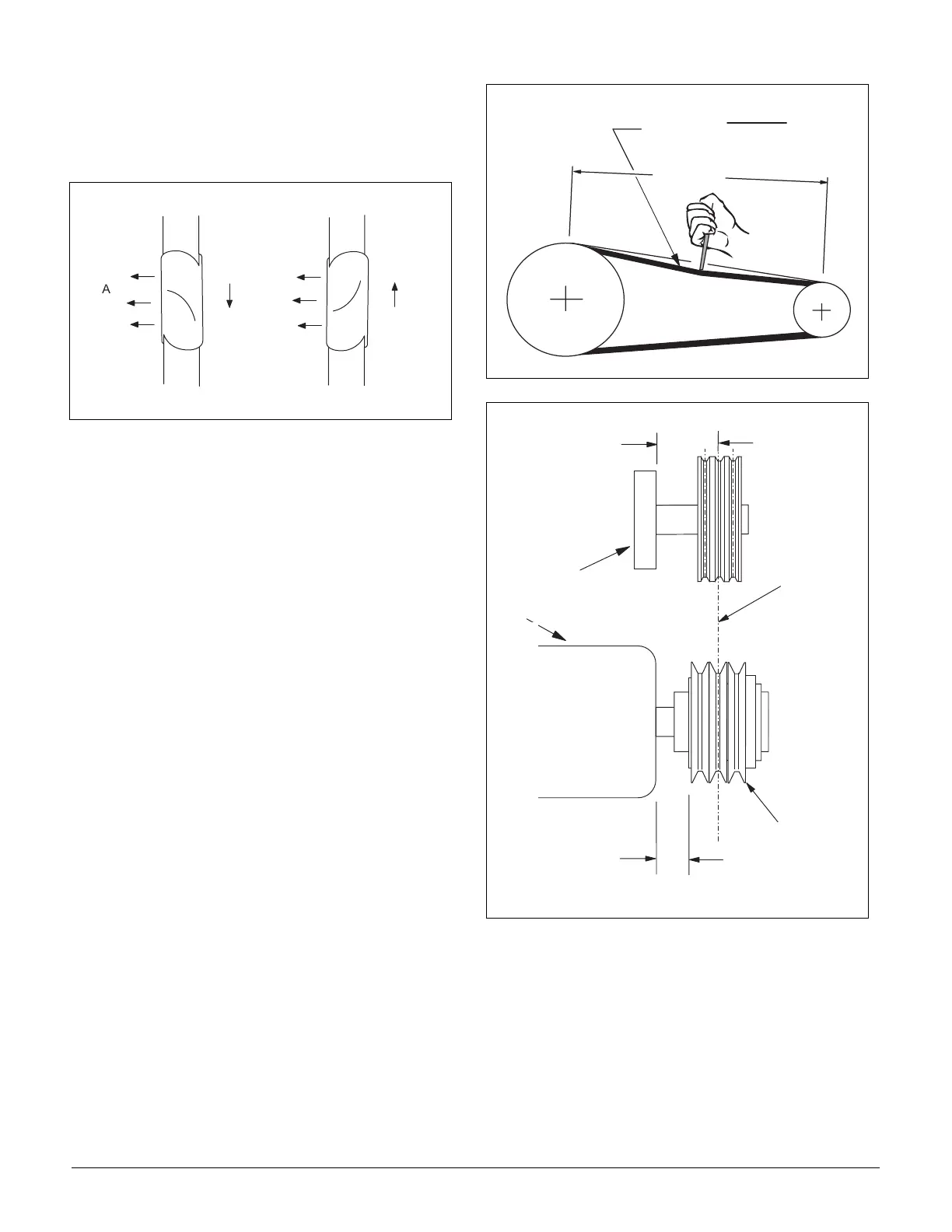

Premature belt failures are frequently caused by improper belt

tension (either too tight or too loose) or misaligned pulleys.

The proper tension for operating a V-belt is the lowest tension

at which the belts will not slip peak load conditions. For initial

tensioning, the proper belt deflection half way between pulley

centers is 1/64" for each inch of belt span. For example, if the

belt span is 64 inches, the belt deflection should be one inch

using moderate thumb pressure at midpoint of the drive,

See Figure 82.

Check belt tension two times during the first 24 hours of oper-

ation and periodically thereafter. To adjust belt tension, simply

loosen four fasteners (two on each side of the motor plate) and

slide the motor plate away from the fan shaft until proper belt

tension is attained. On some fans, fasteners attaching the motor

to the motor plate must be loosened in order to adjust the belt.

It is very important that the drive pulleys remain in proper

alignment after adjustments are made. Misalignment of pulleys

will result in premature belt wear noise, vibration and power

loss, See Figure 83.

Figure 82. Belt Adjustment

Figure 83. Drive Pulley Alignment

Bearings

Bearings are the most critical moving part of the fan and

should be inspected at periodic intervals. Locking collars and

set screws, in addition to fasteners attaching the bearings to the

bearing plate, must be checked for tightness. In a clean envi-

ronment and temperatures above 32°F./below 200° F., fan shaft

bearings with grease fittings should be lubricated semi-annu-

ally using a high quality lithium based grease. If unusual envi-

ronmental conditions exist temperatures below 32°F. / above

200°F., moisture or contaminants, more frequent lubrication is

required.

i r f l o w

A i r f l o w

R o t a t i o n

R o t a t i o n

B e l t S p a n

D e f l e c t i o n =

B e l t S p a n

6 4

C e n t e r l i n e s

m u s t c o i n c i d

M u s t b e

p a r a l l e l

M u s t b e

p a r a l l e l

A d j u s t a b l e

S h e a v e

M o t o r

B e a r i n g

Loading...

Loading...