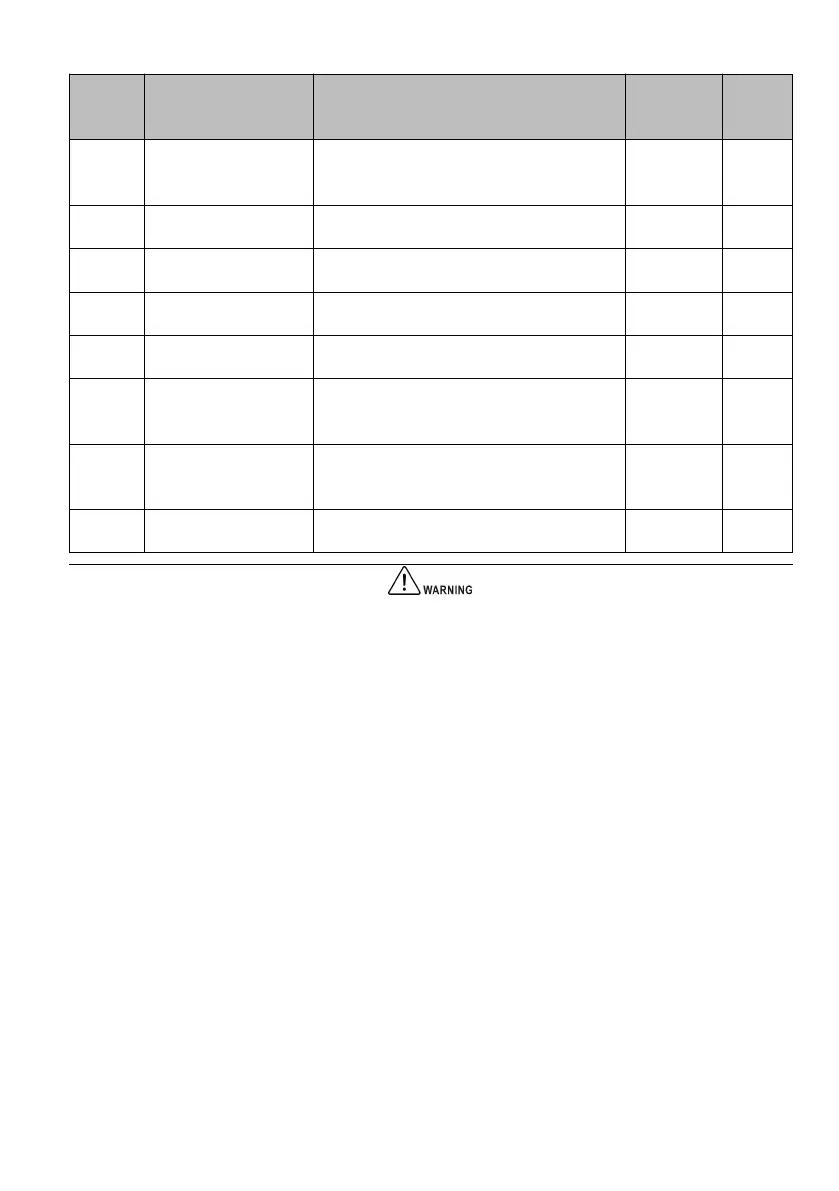

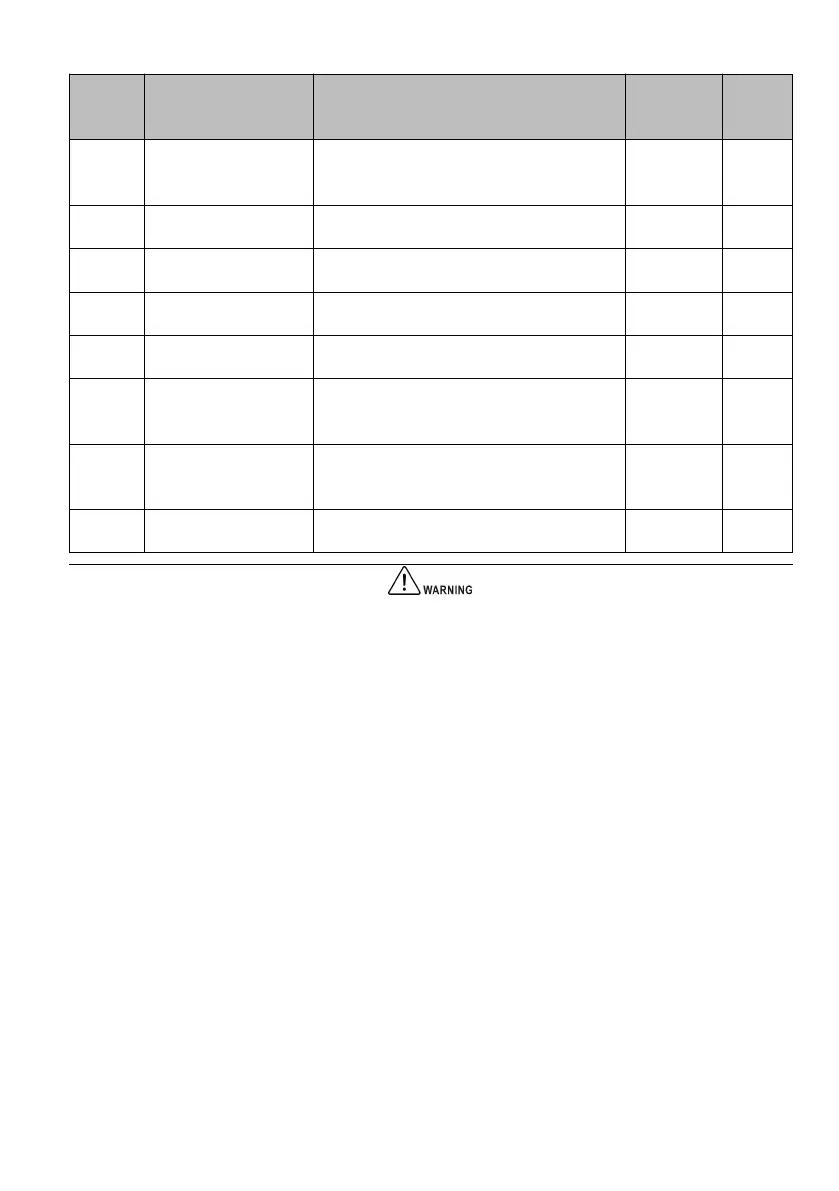

45

Spindle transmission

ratio

0 to 100.0% of maximum frequency

Pulses per revolution of

encoder

Pulses per revolution of

motor

85: Spindle/Positioning homing terminal

(1) The home of spindle/positioning homing can be the Z pulse of the spindle motor (motorized spindle) or the

proximity switch of the spindle (non-motorized spindle). If the transmission ratio of motor shaft to spindle is 1:1, use

the Z pulse of motor encoder as the home position switch. When DI3 is set to 85 (Spindle/Positioning homing

terminal), as long as the input signal is on, the spindle will perform oriented position stop, and DO1

(Spindle/Positioning homing completed) is output after the oriented stop is done. For the spindle homing angle, rotate

the spindle to the desired “zero” position (more than two circles) in the free state until P01.49 changes. Record P01.49

(Current angle of spindle) at the time, and set the value in the parameter P31.07.

(2) When the transmission ratio of motor shaft to spindle is not 1:1, if the encoder is installed at the spindle, set the

tens place of P31.03 to 1, and set the encoder’ pulses per revolution in P04.05. Use the Z pulse of spindle encoder as

the spindle home, and set the spindle encoder’s pulses per revolution P04.07, the spindle transmission ratio P31.05

and the homing mode P31.01 (ORGP as the homing origin) correctly. If the encoder is installed at the motor shaft, an

additional optoelectronic switch is required. Connect the signals of the optoelectronic switch to any terminal of DI6,

DI7 and DI8, set the corresponding terminal function to 84 (position reference input terminal), and set the spindle

encoder’s pulses per revolution P04.07, the spindle transmission ratio P31.05 and the homing mode.

(3) Home searching speed P31.06 is the home searching speed during the oriented specified position stop after the

first power-on.

Loading...

Loading...