39

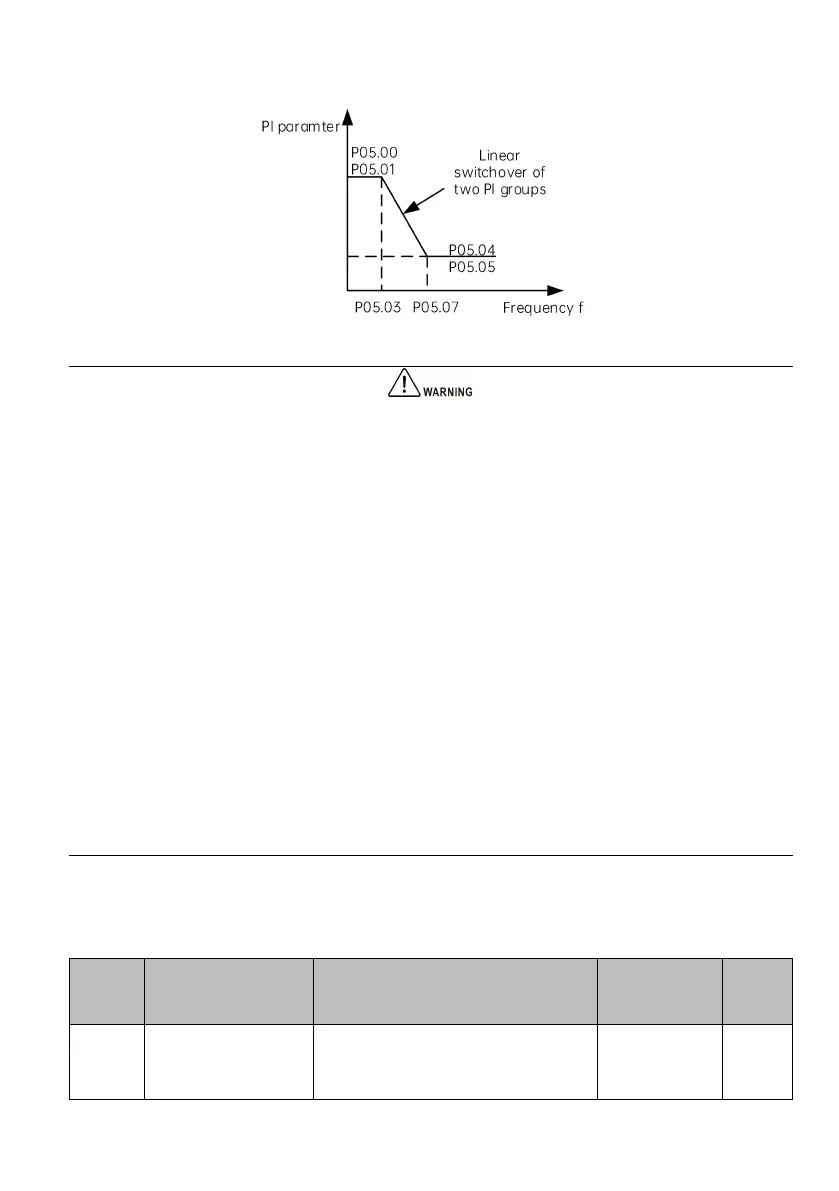

Current loop:

P12.05 and P12.06 are PI adjustment parameters of the current loop. Increasing current loop KP or decreasing I

can enhance the dynamic features of system torque, but too strong regulation may cause device vibration, large

noise, overcurrent during acceleration and other problems upon shaft lock; decreasing KP or increasing I can enhance

the stability of the system.

Speed loop:

Increasing the proportional gain P can accelerate the dynamic response of the system; but too large P will cause

oscillation.

Decreasing the integral time I can accelerate the dynamic response of the system; but too small I will cause large

system overshoots and oscillation.

If the PI parameter is not well selected, the system may produce overvoltage failure (if there is no external braking

resistor or braking unit) after a fast start to high speed, which is due to the energy feedback produced in the

regenerative braking state of system during drop after the speed overshoot. This can be avoided by adjusting the PI

parameter.

Position control

Source of position reference

Servo control

switchover selection

0: Non-servo control

1: Speed/Torque

←→

Servo control

Loading...

Loading...