RIGHT HAND NON-RATCHETING

90-855347R1 JANUARY 1999 Page 6A-39

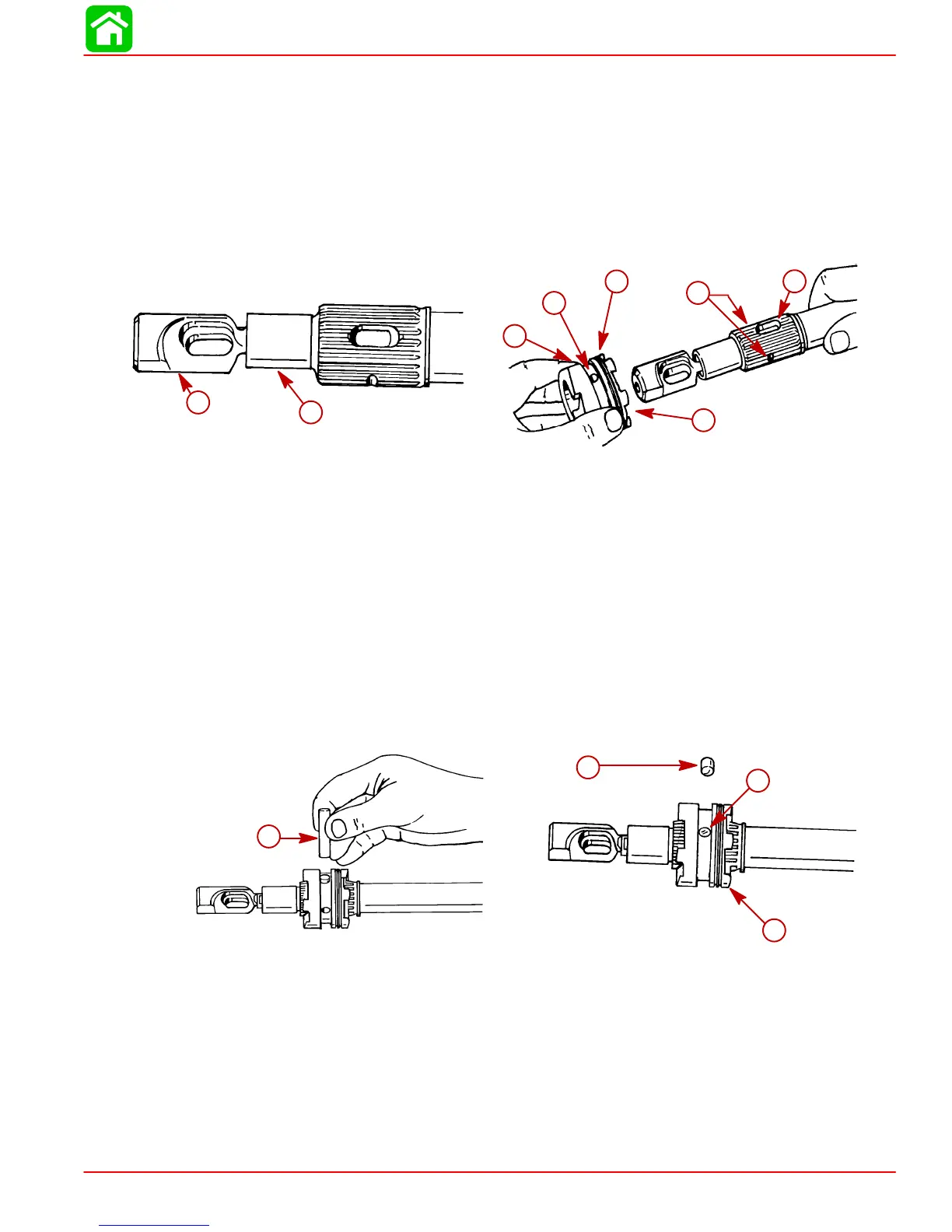

Propeller Shaft

REASSEMBLY/INSTALLATION

1. Insert clutch actuator rod assembly into end of propeller shaft. Align cross pin slot in

actuator rod with cross pin slot in propeller shaft.

2. On PRODUCTION MODEL GEAR CASES, position sliding clutch onto propeller shaft

with GROOVED RINGS (ON SLIDING CLUTCH) TOWARD PROPELLER END OF

PROPELLER SHAFT. Cross pin hole and detent holes (in sliding clutch) must line up

with cross pin slot and detent notches on propeller shaft.

51864

51864

c

d

e

f

g

h

a

b

a-Cam Follower

b-Propeller Shaft

c-Sliding Clutch

d-Grooved Rings

e-Cross Pin Hole

f-Detent Hole (Behind Finger and Thumb)

g-Detent Notch (One on Each Side)

h-Cross Pin Slot

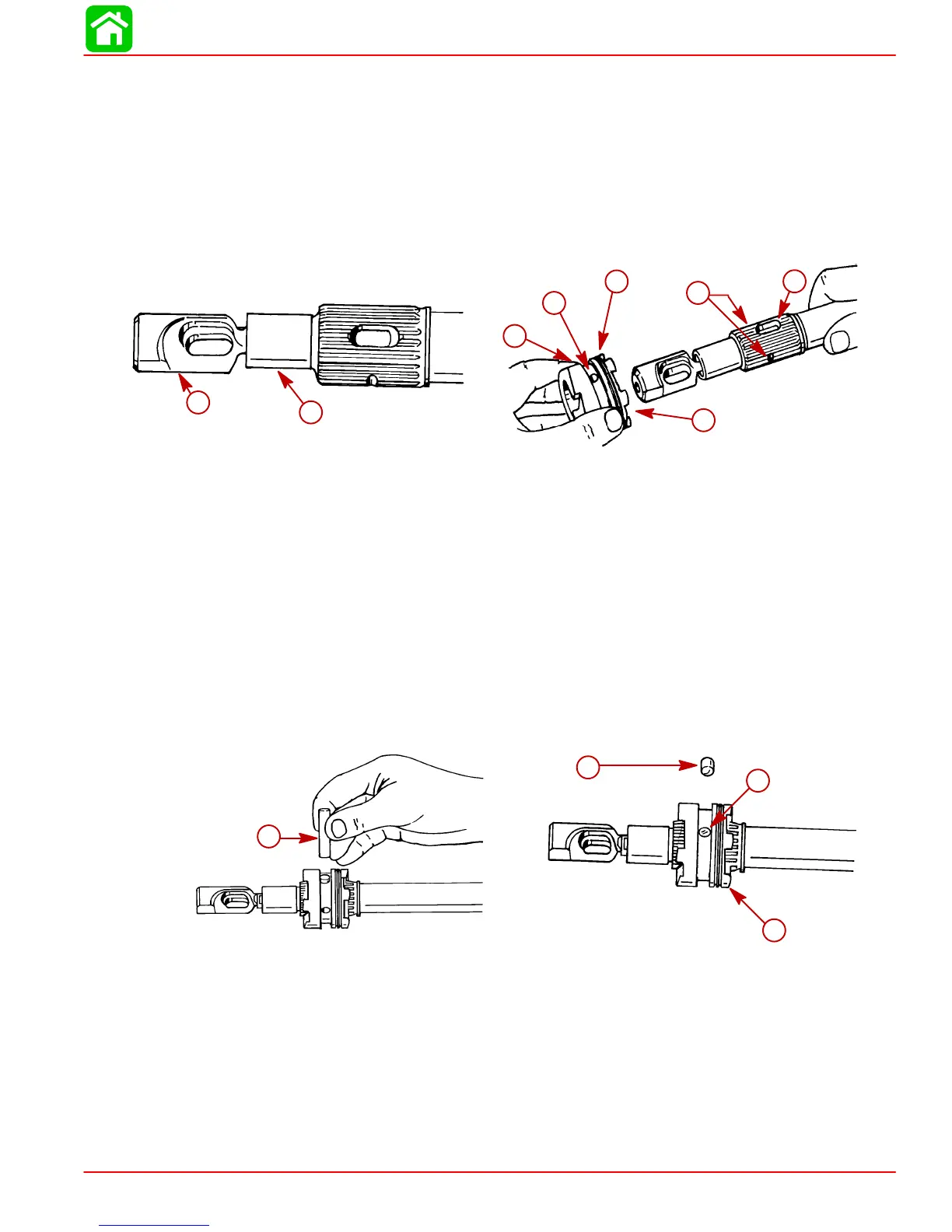

3. Insert cross pin thru sliding clutch, propeller shaft and actuator rod, forcing cross pin

tool out.

4. Apply a small amount of 2-4-C w/Teflon Marine Lubricant on detent pin. Position a det-

ent pin in detent pin hole of sliding clutch with rounded end of pin toward propeller

shaft.

51864

51864

b

c

d

a

a-Cross Pin

b-Detent Pin

c-Cross Pin

d-Sliding Clutch

Loading...

Loading...