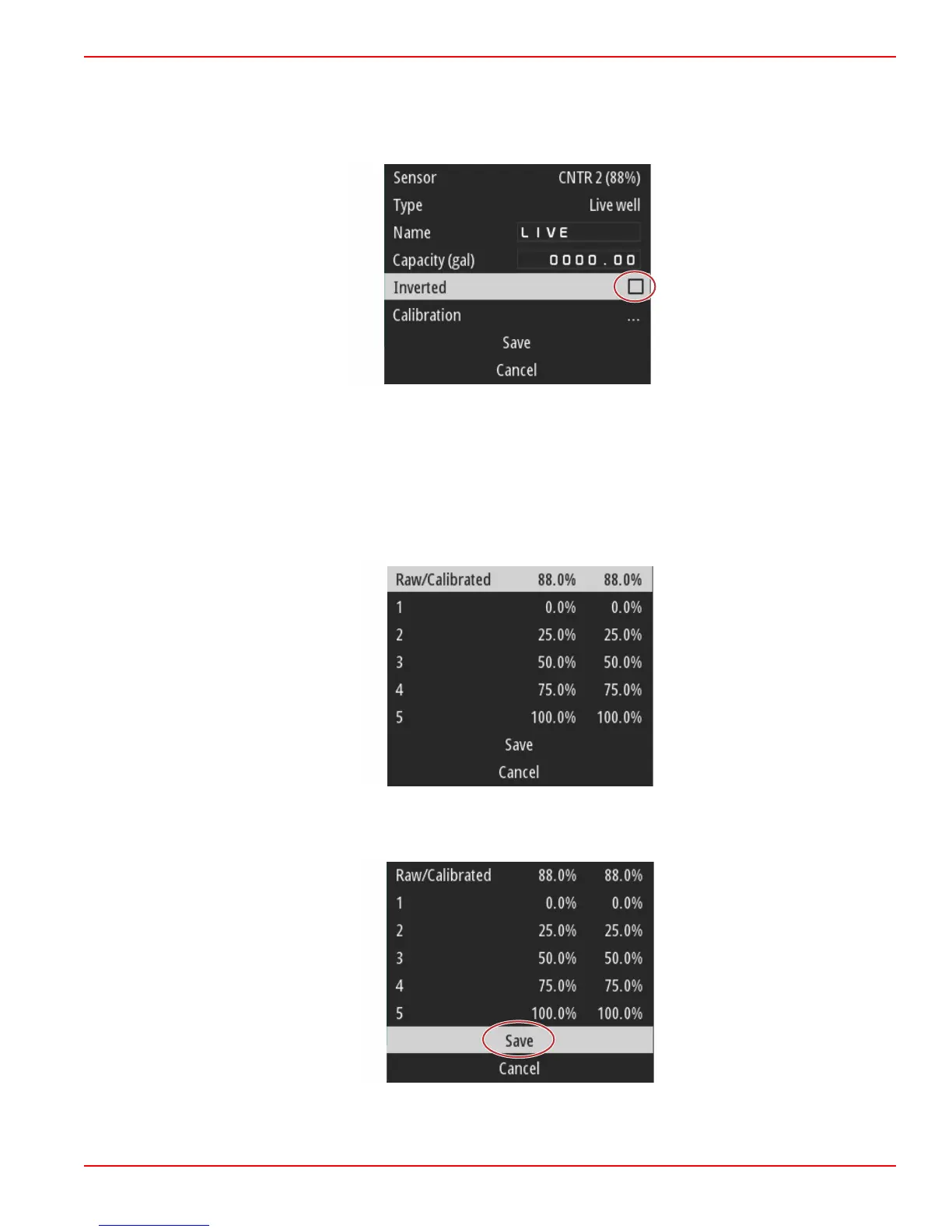

VesselView gives the operator the ability to invert the volume value of the tanks being monitored. This option is available to

accommodate some tank senders that transmit data opposite of traditional standard senders. Standard tank level senders read

a 33–240 ohm resistance. A reading of 240 ohms indicating an empty tank and a reading of 33 ohms indicating a full tank.

Inverted tank senders typically read 0–180 ohms, with 0 ohms indicating a full tank and a reading of 180 ohms indicating an

empty tank.

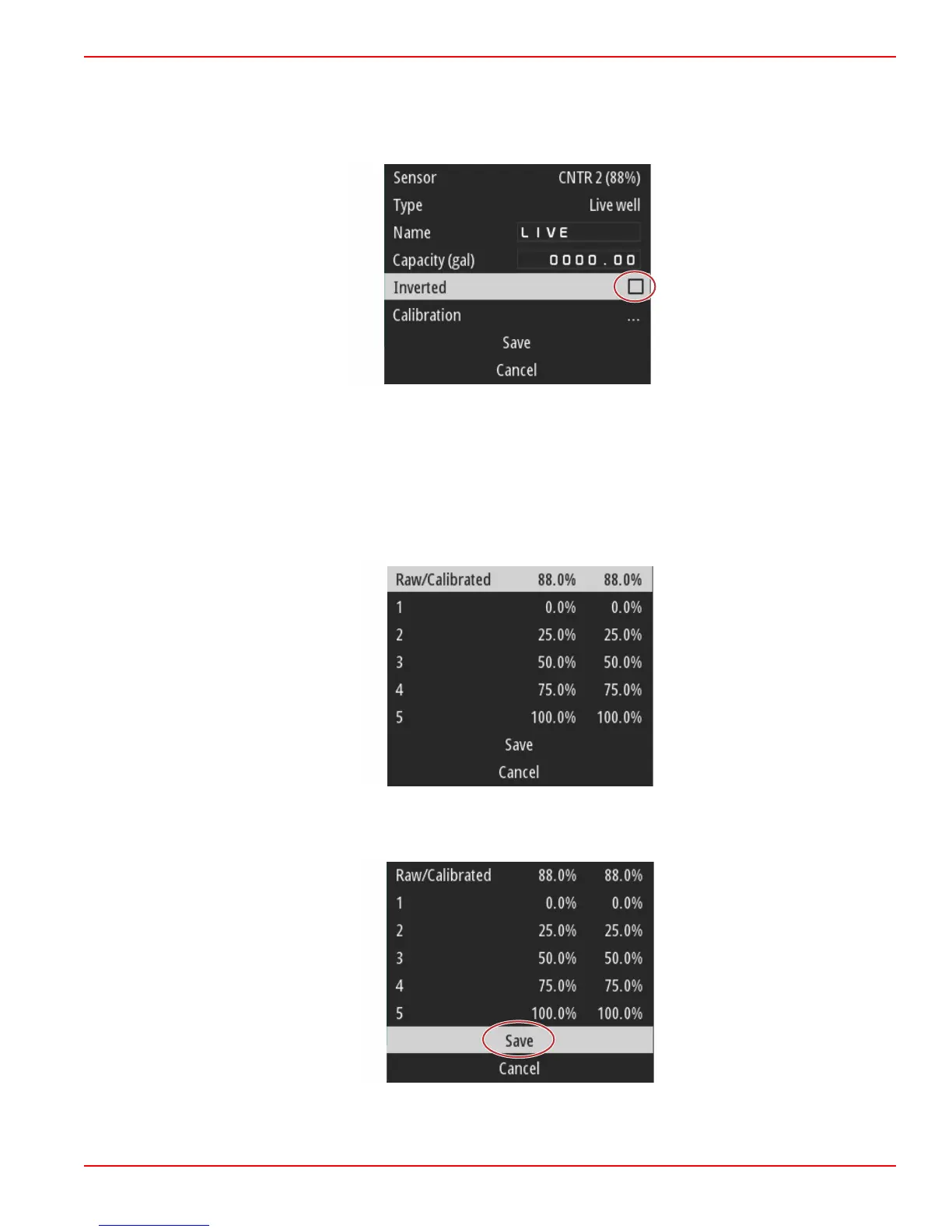

Performing tank calibration: There are many situations in which a tank may need calibration; odd shaped tanks, V‑bottomed

tanks, stepped‑sided tanks, and even a tank's aspect when the boat is in the water. Floats and senders can send inaccurate

data to the operator, causing problems with fuel and other volume display. The most accurate way to achieve tank calibration is

to start with an empty tank with a known capacity. Pump one quarter of the capacity and record the float or sender position.

Repeat this procedure in one quarter increments, recording the float or sensor position each time, until the tank is full. Tank

calibration allows the operator to adjust the full through empty readings of a tank.

Use the Up arrow and Down arrow buttons to highlight the calibration rows. With a row highlighted, press the Enter button to

change the percentage data. Press the Menu button to exit the calibration row.

When all fields and selections have been configured, highlight the Save option and press the Enter button to save the tank

settings into the VesselView.

Section 2 - Initial Screens and Setup Wizard

90-8M0124182 eng DECEMBER 2017 Page 17

Loading...

Loading...