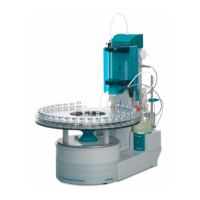

The Metrohm Combustion-IC-System is a comprehensive analytical system designed for the determination of various elements in solid, liquid, and gaseous samples through combustion and subsequent ion chromatography. This manual provides short instructions for the installation and operation of the system, emphasizing safety and proper usage.

Function Description:

The core function of the Combustion-IC-System is to prepare samples for ion chromatographic analysis by combusting them. This process effectively digests the sample, converting the target elements into gaseous forms that can then be absorbed into a solution. This absorption solution is subsequently analyzed by an ion chromatograph. The system is particularly suited for determining elements such as halogens (F, Cl, Br, I), sulfur, and phosphorus.

The overall process involves several key steps:

- Sample Input: The sample (solid, liquid, or gaseous) is introduced into the Combustion Module (AJ) or Combustion Oven (TEI).

- Combustion: The sample is combusted, generating gases containing the target elements.

- Absorption of Combustion Gases: The combustion gases are directed to the 920 Absorber Module, where they are dissolved into an absorber solution. This step often involves specific sample preparation techniques to optimize the solution for analysis.

- Loop Filling: The absorption solution is then used to fill a loop within the system.

- Matrix Elimination (Optional): For certain applications, a matrix elimination step may be performed using the 930 Compact IC Flex to remove interfering substances.

- IC Determination: The preconcentrated absorption solution is finally analyzed by the ion chromatograph (930 Compact IC Flex).

- Rinsing: After analysis, the absorber tube and other components are rinsed.

The entire process is controlled and monitored by MagIC Net software, which also saves the analysis data in its database.

Important Technical Specifications:

The Combustion-IC-System is modular, and its components vary depending on the sample type and application. Key instruments include:

- Combustion Module with Auto Boat Drive (ABD) (Analytik Jena 2.136.0700): Used for solid/liquid samples. Can be optionally equipped with a sampler (MMS 5000).

- Combustion Module with LPG/GSS Module (Analytik Jena 2.136.0730): Used for gaseous samples. The LPG/GSS Module (2.136.0720) facilitates the feeding of gaseous samples to the Combustion Module.

- 920 Absorber Module (Metrohm 2.920.0010): This module is central to the absorption process. It features a 10-port valve and a 6-port valve for managing various solutions (absorber solution, standard solution, check standard, waste, ultrapure water). It also includes a Peltier cooler for cooling combustion gases.

- 930 Compact IC Flex Oven SeS/PP/Deg (Metrohm 2.930.2560): This is the ion chromatograph responsible for the final analysis.

Capillary and Tubing Connections:

The system relies on a network of capillaries and tubings for fluid transfer. Specific connections are detailed for the 920 Absorber Module, including:

- PTFE capillaries (0.75 mm ID / 3 m, 6.1803.160): Used for various connections, including to the 6-port valve, 10-port valve, waste container, standard solution, check standard, and absorber tube.

- PEEK capillary (0.5 mm ID / 15 cm, 6.1831.040): Connects the 6-port valve to the 10-port valve.

- FEP tubing M6 for 920 (6.1805.030, 6.1805.010): Used for aspiration tubing for absorber solution and ultrapure water, connecting to the Dosino and T connector.

- PTFE capillary (0.5 mm ID / 3 m, 6.1803.030): Connects the 6-port valve to the 930 Compact IC Flex.

- PTFE capillary (1/8 / 1/16 ID / 1.5 m, 6.1803.130): Used for combustion gases.

Dosino for Ultrapure Water (2.800.0020): Connects to various ports (6.1803.030, 6.1805.010, 6.2744.350, 6.2744.080, 6.2057.230, 6.1618.020, 6.07311.310 (TEI)) for ultrapure water supply.

Dosino for Absorber Solution (2.800.0020): Connects to various ports (6.1803.030, 6.1805.010, 6.2744.350, 6.2744.080, 6.1819.100, 6.2057.230, 6.1618.020) for absorber solution management.

Combustion Tube Inlet (TEI): Features connections for Argon infeed, Oxygen infeed, and Water infeed.

Combustion Oven (TEI) Outlet: Features connections for absorber solution capillary and combustion gases capillary.

Usage Features:

- Automated Operation: The entire determination process is controlled by MagIC Net software, allowing for automated and reproducible analyses.

- Modular Design: The system's modularity allows for configuration based on specific sample types (solid, liquid, gaseous) and analytical needs.

- Software Control: MagIC Net software provides comprehensive control and monitoring of the system, including method loading, equilibration, and data management.

- Safety Features: The manual highlights critical safety instructions, including warnings regarding supply voltage, electrostatic charges, flammable solvents and chemicals, and proper handling of tubing and capillary connections.

- Clear Workflow: The sequence of determination is clearly outlined, from sample input to IC analysis, ensuring a structured approach to operation.

- Color-Coded Sleeves: The use of color-coded sleeves (e.g., blue for water infeed, yellow for absorber solution, black for standard solution, red for check standard, white for waste) on capillaries helps in easy identification and correct connection, especially when heat-shrunk for secure attachment.

Maintenance Features:

- Regular Connection Checks: It is mandatory to regularly check tubing and capillary connections for leakage, especially in unattended operation (weekly inspections are recommended).

- Proper Disposal: The manual provides guidelines for the correct disposal of the old instrument, emphasizing environmental and public health considerations.

- Authorized Service: Only Metrohm-qualified personnel are authorized to carry out service work on electronic components, ensuring proper maintenance and preventing damage.

- Documentation: Detailed instructions for installation and maintenance of individual components are available in accompanying manuals and online resources (www.metrohm.com), facilitating troubleshooting and upkeep.

- Capillary Shortening: Instructions are provided for shortening capillaries using a capillary cutter to ensure easy and secure connections to various ports.

- Adapter Disassembly: For the LPG/GSS Module, instructions include disassembling individual components of the adapter for maintenance or setup.