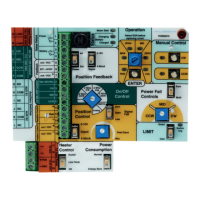

1. GENERAL

1.1 Scope of the Manual

This instruction manual contains important information

regarding the installation, operation and maintenance of

the Valvcon V-Series electric actuator. Please read these

instructions carefully and save them for future reference.

1.2 Actuator Markings

WARNING

AS THE USE OF THE ACTUATOR IS APPLICATION SPECIFIC, A

NUMBER OF FACTORS SHOULD BE TAKEN INTO ACCOUNT

WHEN SELECTING AN ACTUATOR FOR A GIVEN APPLICATION.

THEREFORE, SOME OF THE SITUATIONS IN WHICH THE ACTUATORS

ARE USED ARE OUTSIDE THE SCOPE OF THIS MANUAL. IF YOU

HAVE ANY QUESTIONS CONCERNING THE USE, APPLICATION OR

COMPATIBILITY OF THE ACTUATOR WITH THE INTENDED SERVICE,

CONTACT METSO FOR MORE INFORMATION.

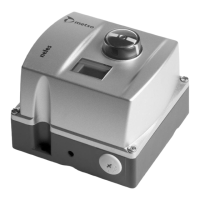

The actuator has an identication label attached to the

base casting (see Figure 1).

( 1 )

( 2 )

( 7 )

( 8 )

( 9 )

( 3 )

( 5 )

( 6 )

( 4 )

Figure 1 Identication Plate

Identication label markings:

1. Model number

2. Serial number

3. Maximum output torque

4. Voltage

5. Current draw (full-load running)

6. Cycle time

7. Duty cycle

8. Applicable manual

9. Certications marking

1.3 Saftey Precautions

WARNING

DO NOT EXCEED THE ACTUATOR PERFORMANCE LIMITATIONS!

EXCEEDING THE TORQUE LIMITATIONS MARKED ON THE ACTUATOR

IDENTIFICATION LABEL MAY CAUSE DAMAGE TO THE ACTUATOR

AND/OR FINAL DRIVE ELEMENT.

WARNING

DO NOT EXCEED THE ACTUATOR ELECTRICAL LIMITATIONS!

EXCEEDING THE ELECTRICAL LIMITATIONS MARKED ON THE

ACTUATOR IDENTIFICATION LABEL MAY CAUSE DAMAGE TO THE

ACTUATOR AND/OR PERSONAL INJURY.

WARNING

BEWARE OF MOVEMENT OF THE FINAL DRIVE ELEMENT AND ANY

LINKAGE BETWEEN IT AND THE ACTUATOR!

KEEP HANDS, OTHER PARTS OF THE BODY, TOOLS AND OTHER

OBJECTS OUT OF THE WAY OF MOVING PARTS. FAILURE TO DO THIS

MAY RESULT IN DAMAGE OR PERSONAL INJURY!

2. TRANSPORTATION AND STORAGE

Check the actuator and any accompanying devices for any

damage that may have occurred during transport.

Store the actuator carefully. Storage indoors in a dry place is

recommended.

Move the actuator to its intended location just before

installation.

The actuator is usually shipped in the full clockwise,

(typically closed) position.

If the actuator(s) will be stored for a period longer than 90

days, follow the recommendations in IMO-S2 to maintain

the actuator’s integrity.

3. GENERAL INSTALLATION

INFORMATION

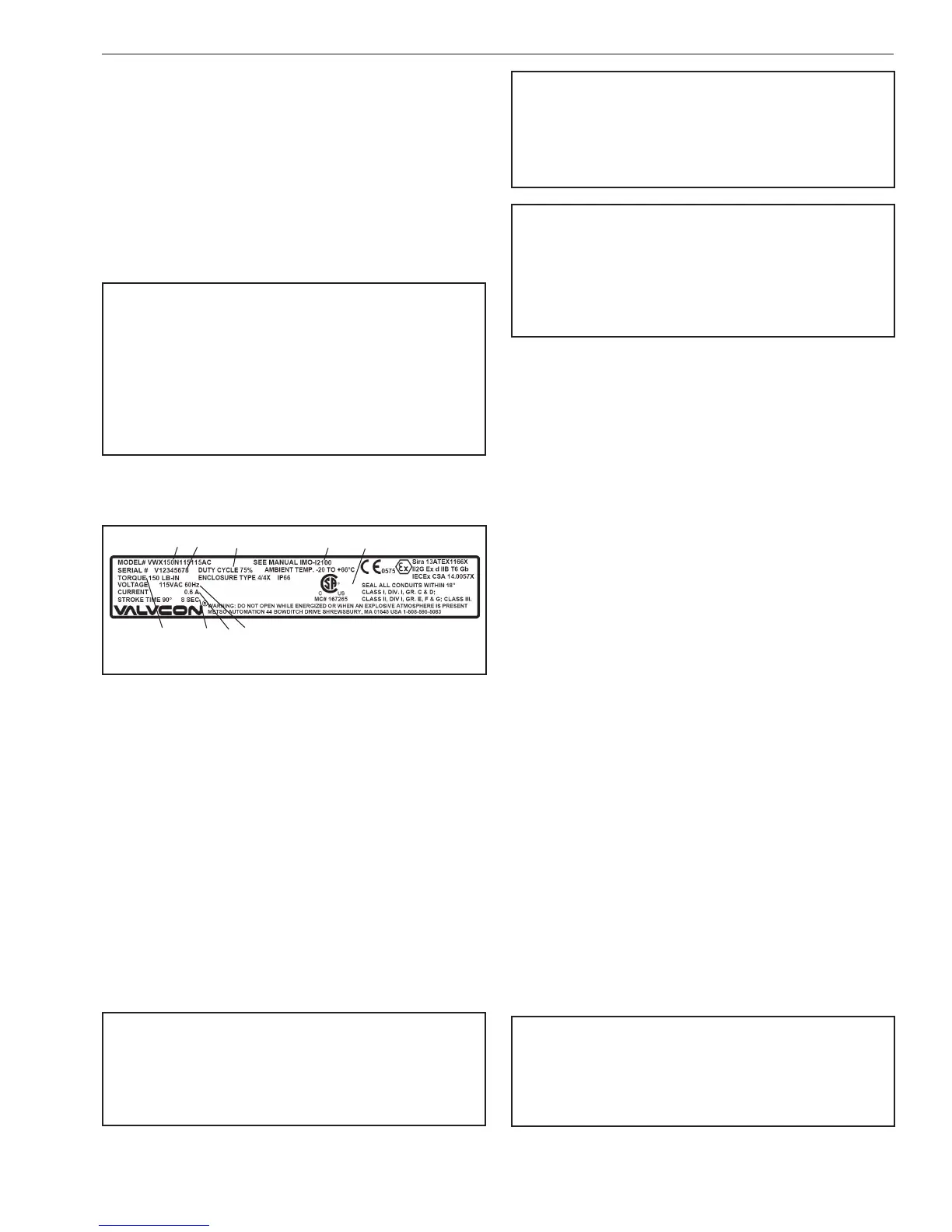

3.1 Description of Control Board P/N

VC002975 for Modulating Applications

The Control Board connects to the Motor Board with a 10

position plug-in connector and 3 mounting screws that

are captured in the board. The Control Board allows the

actuator to modulate (change position) in response to a

change in an analog control signal. The input control signal

may be either current, such as 4-20 mA, or voltage such

as 0-10 VDC, or 2-10 VDC. The control board also features

analog position feedback, signal fail options, speed control,

locked rotor/stall protection, simple push button set-up,

and auto calibration.

WARNING

DANGEROUS VOLTAGES ARE PRESENT INSIDE THE ACTUATOR

COVER UNLESS THE POWER SUPPLY TO THE ACTUATOR HAS BEEN

SHUT OFF OR DISCONNECTED. USE EXTREME CAUTION WHENEVER

WORKING ON THE ACTUATOR WITH THE COVER REMOVED.

Loading...

Loading...