3.2 Operating Modes

The Control Board has ve operating modes. Run, Manual,

Set Span, Set Zero and CAL (calibrate). A rotary “Mode

Selector Dial” on the Control Board allows the user to

change the operating mode. To change mode, turn the

rotary selector knob with ngers or a small screwdriver.

Five LED indicators around the knob correspond to one of

the ve modes. When the Control Board mode dial is set to

any mode, the corresponding LED turns on, indicating the

mode is selected.

• Run mode is the basic operating mode. The actuator will

respond to a command control signal which is supplied

to terminal A and terminal B on the Control Board.

• Manual mode permits the user to override the control

signal and drive the actuator by using the [CW] and

[CCW] push buttons. In Manual mode the actuator will

not travel beyond the saved settings for the Zero and

Span stop positions.

• Set Span mode permits the user to precisely

correlatethe end of span travel stop with a

corresponding control signal value. Typically, the Span

position is the fully counter-clockwise position and

maximum control signal value, but Span may be set at

any position or signal value.

• Set Zero mode permits the user to precisely correlate

the opposite end of travel stop position with a

corresponding control signal value. The Zero position

is typically the fully clockwise position and minimum

control signal value, but Zero may be set at any position

or signal value.

• Cal mode allows the user to automatically calibrate the

position tracking potentiometer without the use of an

ohmmeter or other electronic instruments.

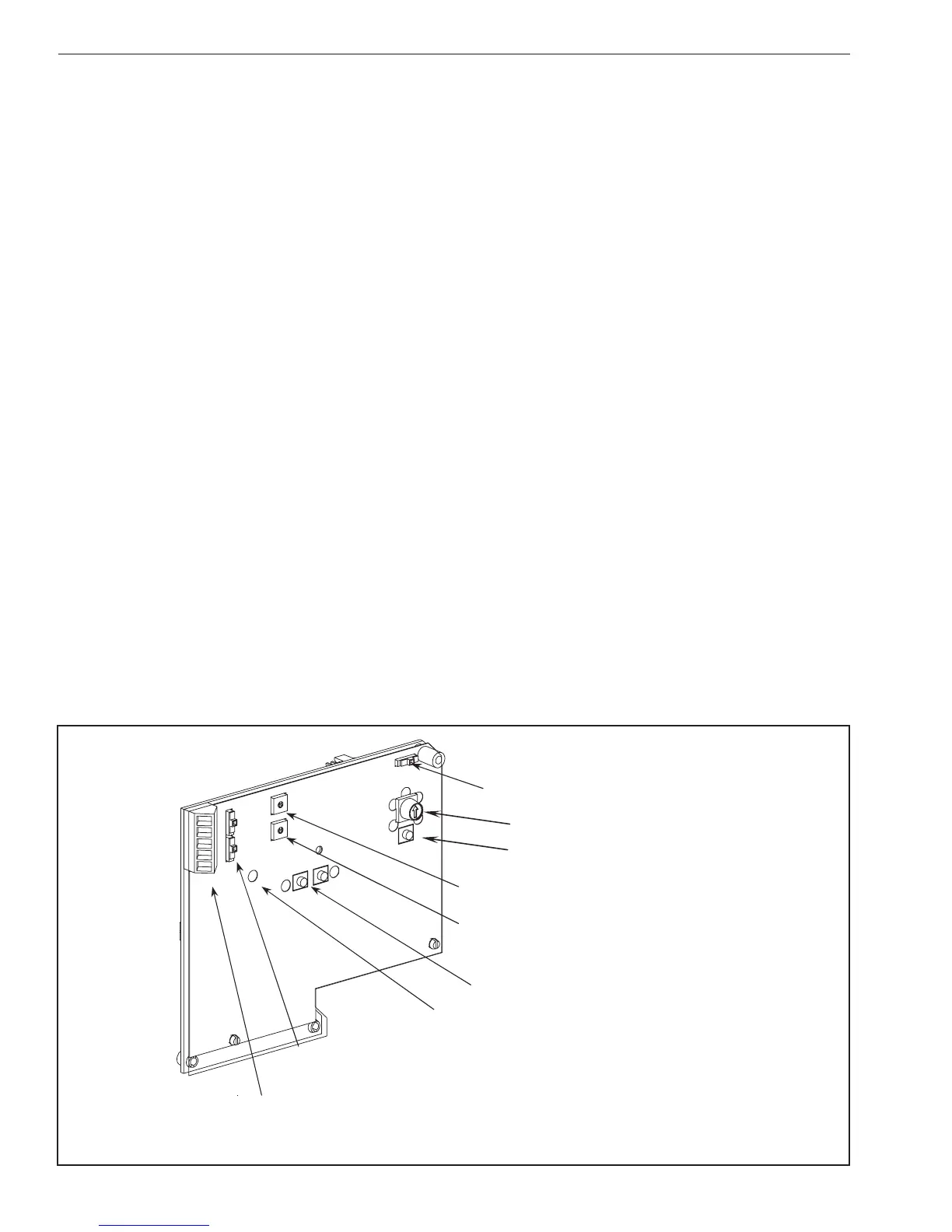

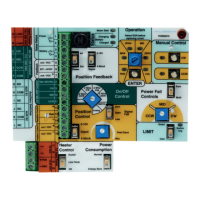

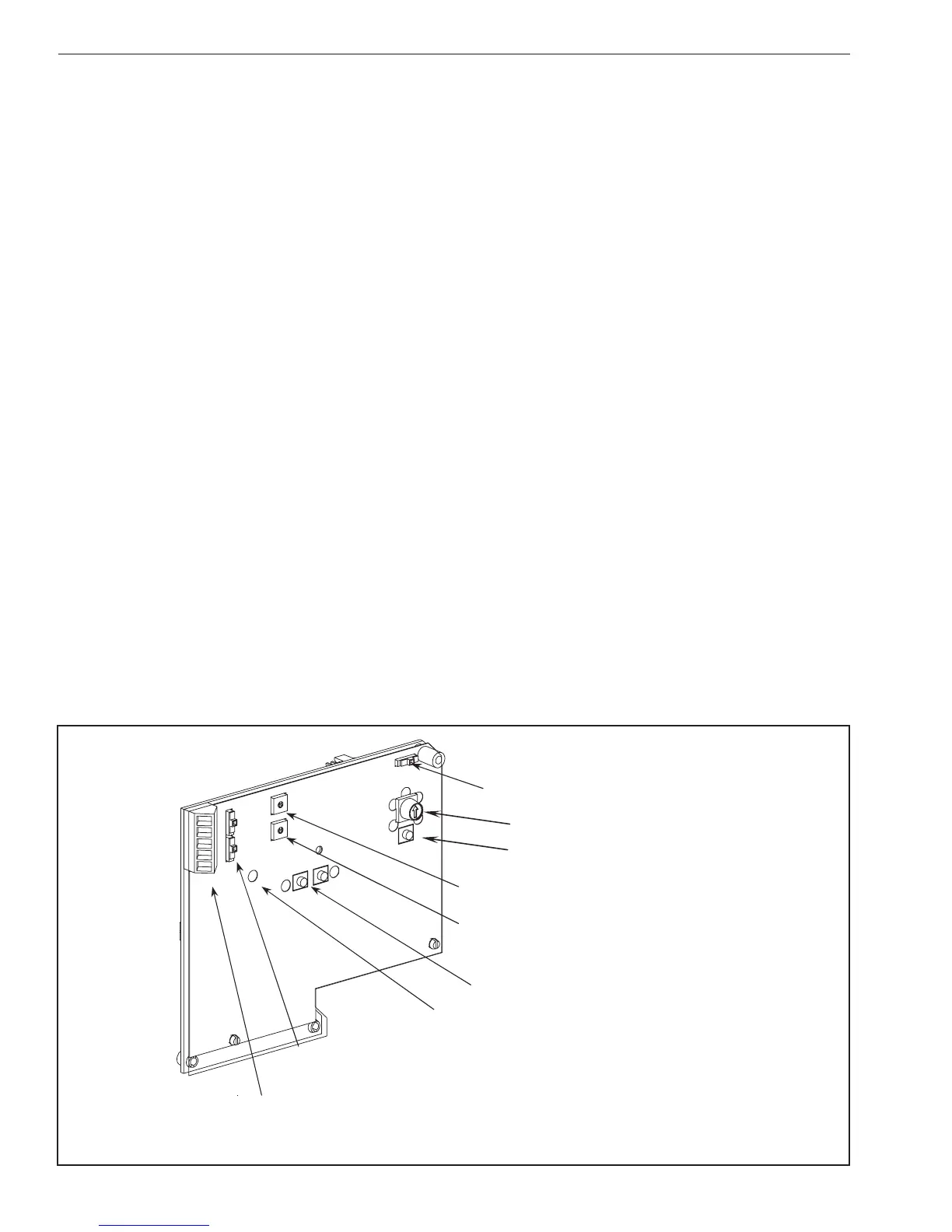

3.2.1 Features, Settings and Controls

The control board is designed to be easy to use and hard to

break. Set Up is push button simple and takes one minute!

See (Figure 2) for callouts.

• Enter is located directly below the mode selector

and permits the user to activate modes and conrm

settings by pressing the [ENTER] button.

• Control Signal Selection The board can accept either

current or voltage control signals. Make sure the Input

Signal Select switch is correctly positioned for the

input control signal.

• Feedback Signal Selection The board provides a

feedback signal indicating actuator output position.

This signal can be either current or voltage. Make

sure the Feedback Signal Select switch is correctly

positioned for the desired feedback signal. If the

feedback signal is not used, the switch may be left in

either position.

• Control Fail Position In the event that the control

signal to the actuator is lost and power is still applied,

the Signal Fail Position Selector Switch on the Control

Board provides for the actuator to remain at its

LAST (current) position or drive the actuator to the

“ZERO” position. The actuator will maintain the LAST

position or Zero position until a control signal returns

Control Fail Position Switch

Mode Selector Dial

[Enter]

Speed Control Dial

Deadband Adjust Dial

[CW] and [CCW] Push Buttons

Stall LED Alarm

Input Signal & Feedback Signal Switches

Control Signal Input & Feedback Output Terminals

Figure 2

Loading...

Loading...