to terminal A and terminal B. NOTE: If you use a 0-10

VDC control signal, the actuator will drive to the zero

position regardless of the switch setting.

• Manual Supervisory Control Selecting Manual (Man)

Mode will override the connected control signal and

allow driving the actuator to any position between

Zero and Span, using the CW and CCW push buttons.

There is no need to disconnect or handle live wires.

• Deadband Deadband is the window of control signal

change which the actuator will ignore. The sensitivity

of the actuator to respond to changes in the control

signal is adjustable. Minimum deadband allows the

actuator to respond to small control signal changes.

Maximum deadband allows the actuator to ignore

small control signal changes (such as noise on the

control signal). Deadband adjustment from Minimum

to Maximum varies the dead band from small (1%) to

large (3%) of input signal. The deadband should be set

to the maximum amount which the process will allow.

• Speed Control The Control Board will slow the actuator

by pulsing the motor if the Speed Control feature is

utilized. The speed of the actuator can be regulated

from 1:1 (normal) to 20:1 (1/20th of the normal cycle

time) by adjusting the “Speed Control” dial on the

Control Board.

• Stall (Locked Rotor Protection) Locked rotor

protection prevents the overheating of the motor and

possible premature failure. The Control Board provides

locked rotor protection and Stall LED Alarm in the event

of a stall condition such as a jammed valve or damper.

Should the actuator stall before reaching the position

commanded by the control signal, the actuator will

remove power to the motor within 2-5 seconds. The

Stall LED on the Control Board will continue to ash

until a reverse control signal clears the stall condition.

NOTE: If the process does not allow for controller

signal reversal; the stall can be cleared by selecting

MAN mode and driving the actuator manually using

the CW or CCW push buttons. Be sure to select RUN

before replacing cover.

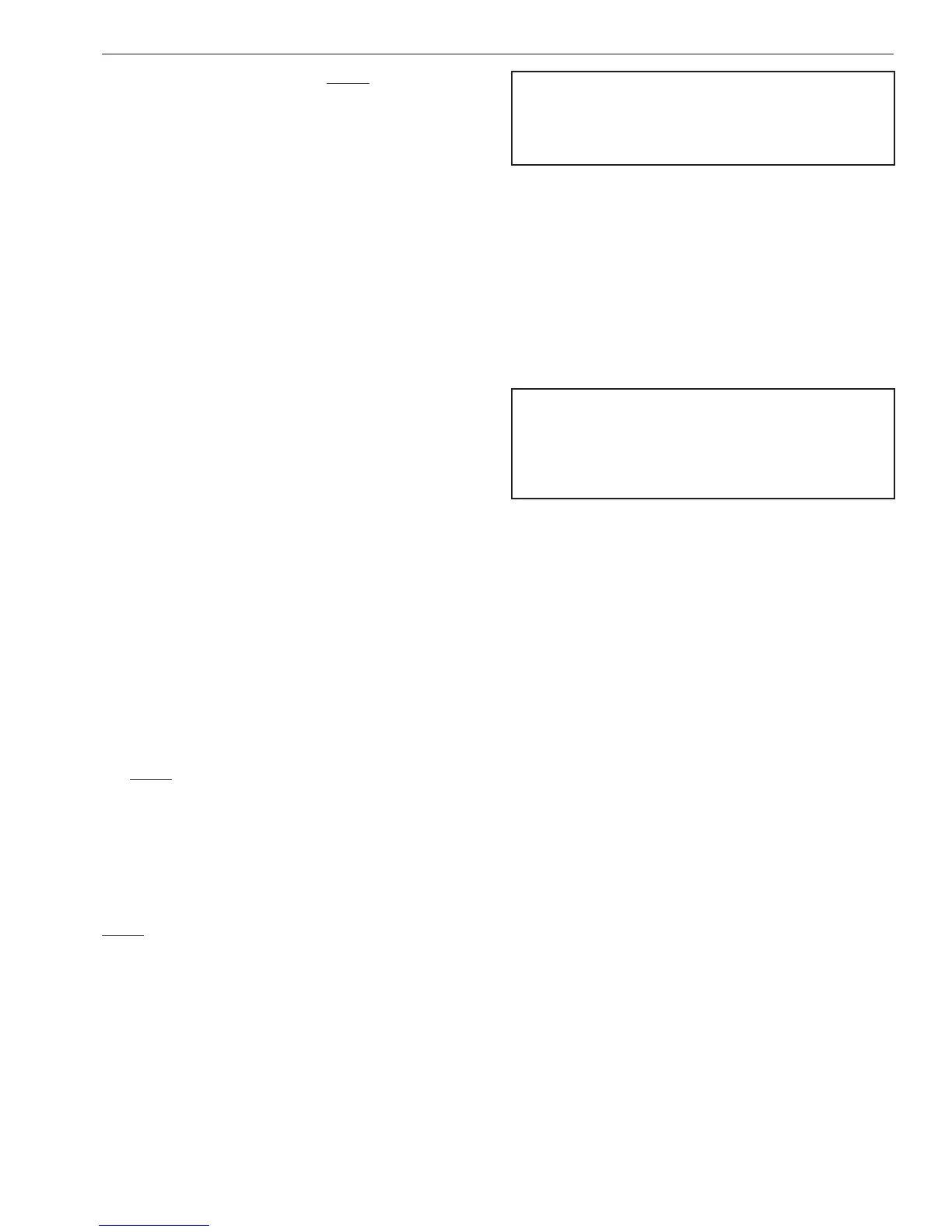

3.3 Control Board Wiring

NOTE: Assumes option is installed; if installing kit, see

section 3.5 of this manual.

To operate the actuator with the Control Board installed, the

user must supply power to terminal 1 and terminal 2, only!

Power to terminal 3 and terminal 4 can cause damage to

the Motor Board. See (Figure 3) for Diagram. Control signal

wiring to the Control Board terminals should be properly

shielded. To further prevent control signal noise, control

signal wiring should be separated from the power wiring

and should enter the actuator through a conduit opening

separate from the entry used for the power wiring.

WARNING

ACTUATORS SHOULD BE PROPERLY GROUNDED AND WIRED IN

ACCORDANCE WITH LOCAL ELECTRICAL CODE; SEE NAMEPLATE

FOR MAXIMUM CURRENT DRAW.

Terminal 5, counter-clockwise, and terminal 6, clockwise,

position indication does not apply to actuators with the

Control Board option. If status feedback is required with the

Control Board option, install optional limit switches or use

the standard readback feature provided with the Control

Board. See (Section 4) for additional switches.

3.4 Operation for Modulating Applications

(Motor Board and Control Board

Installed) (90˚ Rotation)*

WARNING

WHEN CONTROL BOARD IS INSTALLED, POWER TO TERMINAL 3

OR TO TERMINAL 4 WILL DAMAGE ELECTRONIC CIRCUIT BOARDS.

POWER TERMINALS 1 AND 2; USE CW CLOCKWISE AND CCW

COUNTERCLOCKWISE BUTTONS TO DRIVE ACTUATOR.

3.4.1 Set Up for Operation

1. Remove actuator cover.

2. Select Input Control Signal type – “mA” or “VDC”

(current or voltage), the actuator will accept 4-20 mA

or 0-10 VDC. The unit will also accept a split range

signal, i.e. 4-12 mA, 12-20 mA or a 2-10 VDC signal.

Slide the [INPUT SIGNAL] switch up to select mA or

down to select VDC.

3. Select Output Feedback Signal type – “mA” or “VDC”

(current or voltage), the actuator will provide a 4-20

mA or 0-10 VDC feedback signal. Slide the [FEEDBACK

SIGNAL] switch up to select mA or down to select VDC.

4. Select Signal Fail Position – “Zero” or “Last” – Slide the

[SIGNAL FAIL] to the right to select Zero or to the left

to select Last. Selecting Zero will drive the actuator

to the minimum signal position upon loss of control

signal. If Last is selected the actuator will remain in

place upon loss of control signal. If using 0 VDC as

the minimum signal, the actuator cannot dierentiate

between a commanded minimum signal or a loss of

signal; therefore, Zero should be selected.

3.4.2 Potentiometer Calibration

• Calibration Field installation of the Control Board

option or replacement of the position tracking

potentiometer requires calibration of the position

tracking potentiometer prior to setting positions

and values for Zero and Span. Control Board options

installed at the factory are fully calibrated at the factory

and should not require further calibration. To conrm

proper potentiometer calibration:

Loading...

Loading...