2. Install the override shaft on the square motor shaft; if

the actuator is equipped with a handwheel, install the

bottom piece of the “two-piece” shaft on the motor

shaft and then install the top piece of the shaft onto

the bottom piece of the shaft.

3. Align cover so that the override shaft will pass through

the override bushing and carefully push it down so that

the cover ange contacts the base ange.

4. Once the cover is properly seated, tighten the screws to

secure the cover; a cross pattern is recommended for

uniform distribution of load.

5. If the position indicator is not seated to the output/cam

shaft, turn until it drops into place in order to ensure

accurate visual position indication.

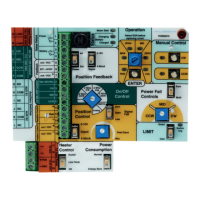

3.5 Board Installation

WARNING

DANGEROUS VOLTAGES ARE PRESENT INSIDE THE ACTUATOR

COVER UNLESS THE POWER SUPPLY TO THE ACTUATOR HAS BEEN

SHUT OFF OR DISCONNECTED. USE EXTREME CAUTION WHENEVER

WORKING ON THE ACTUATOR WITH THE COVER REMOVED.

3.5.1 Tools Required

• Philips Screwdriver

• Hex wrench, 1/16” (supplied with kit)

• Wrench/Nut driver, 1/2”

3.5.2 Installation Instructions

!Disconnect Power!

1. Remove and discard the screw that secures the Motor

Board to the upper bracket. (See Figure 4)

2. Remove 1/2” locking nut from potentiometer (Pot) shaft

and insert pot shaft up through hole in upper support

bracket. Align locking tab and tighten the locking nut

on pot shaft.

3. Plug Pot connector into the 3-Pin connector on the

front of Control Board. Plug Control Board into the

Motor Board via the 10-pin connector. (Note that the

pot wires should be between the two boards)

4. Secure Control Board to Upper and Lower Support

Brackets with the 3 mounting screws. (Note that the 1”

screw goes in the upper-most mounting hole)

5. Place small (20-tooth) gear on Pot shaft and tighten.

Place spacers on Camshaft then place large (60-tooth)

gear on Camshaft. Properly positioned, gears should

mesh evenly.

6. Supply power to terminal 1 and terminal 2, only. (Ax

“No Connect” label; see Figure 4)

Refer to Section 3.4 for Set Up and Calibration

Procedures.

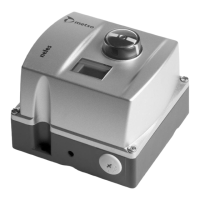

4. VSERIES STANDARD OPTIONS

All V-Series options are designed to be easily installed in the

eld. Options for all standard V-Series actuators are universal

and completely interchangeable with each enclosure size.

For additional V-Series Options, see (Table 3). Voltage is not

eld changeable.

4.1 Option “H” – Tropical Heater and

Thermostat P/N VC099716, VC099723

The tropical heater and thermostat option is a self-adhesive,

resistance heater strip which is applied to the primary

gearbox. It installs with a plug-in connector and is

recommended in high-humidity applications. The tropical

heater option is also recommended in installations that

experience wide temperature swings in order to evaporate

any condensation. Thermostat is pre-set to activate at or

below 90˚F (32˚C) and deactivate at or above 110˚F (43˚C).

The tropical heater draws 15 watts at 115 VAC; 40 watts at

230 VAC (see IMO-I9500 for additional reference).

Option “H” Tropical Heater and Thermostat

Option “T” Standard Heater and Thermostat

Figure 5

Figure 6

Option ”K” - Mechanical Brake

Loading...

Loading...