OM-257 798 Page 27

Ref. 245 744-A / Ref. 259 144-A / Ref. 259 119-A

1 Welding Power Source

2 Electrode Cable

3 Feeder Cable

4 Work Cable

5 Voltage Sense Lead

6 Wire Feeder

7 Workpiece

The arrangement of the cables has an

effect that is significant to the welding

properties. As an example, Accupulse

welding process can produce high

welding circuit inductance depending

on cable length and arrangement. This

can result in limited current rise during

droplet transfer into the welding puddle.

The sense lead is contained in the

feeder control cable and automatically

becomes enabled for all

semi-automatic processes. The work

sense lead connects to the welding

power source 4-pin connector located

above the positive output terminal. This

work sense lead automatically compen-

sates for work cable voltage drop when

connected to the welding power source.

Do not coil excess cables. Use cables

that are the appropriate length for the

application. Whenever using long weld

cables [longer than 50 ft (15 m)] try to

arrange positive and negative weld

cables together to reduce the magnetic

field surrounding the cables. Avoid

coupling the feeder and work sense

leads with the weld cables.

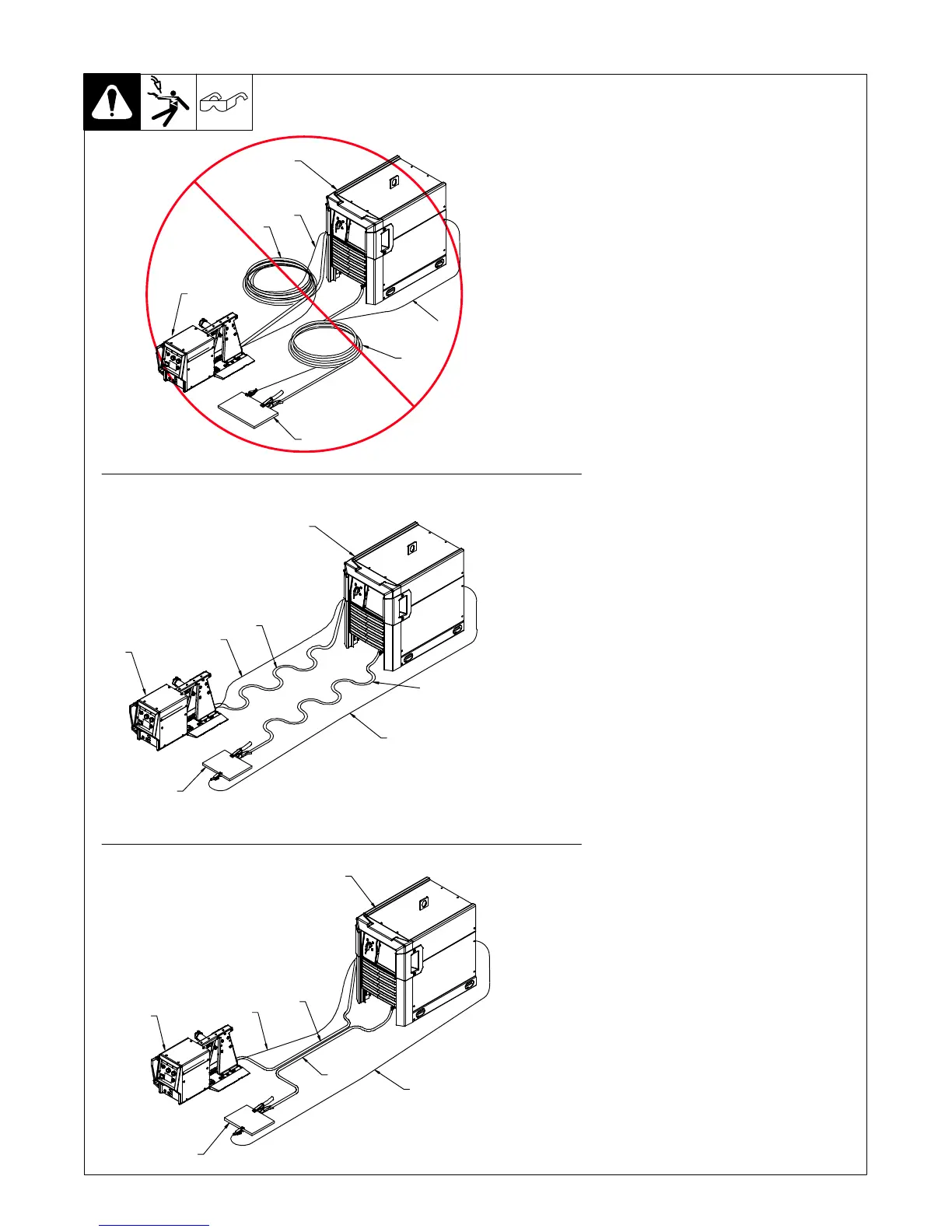

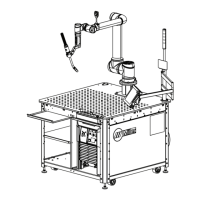

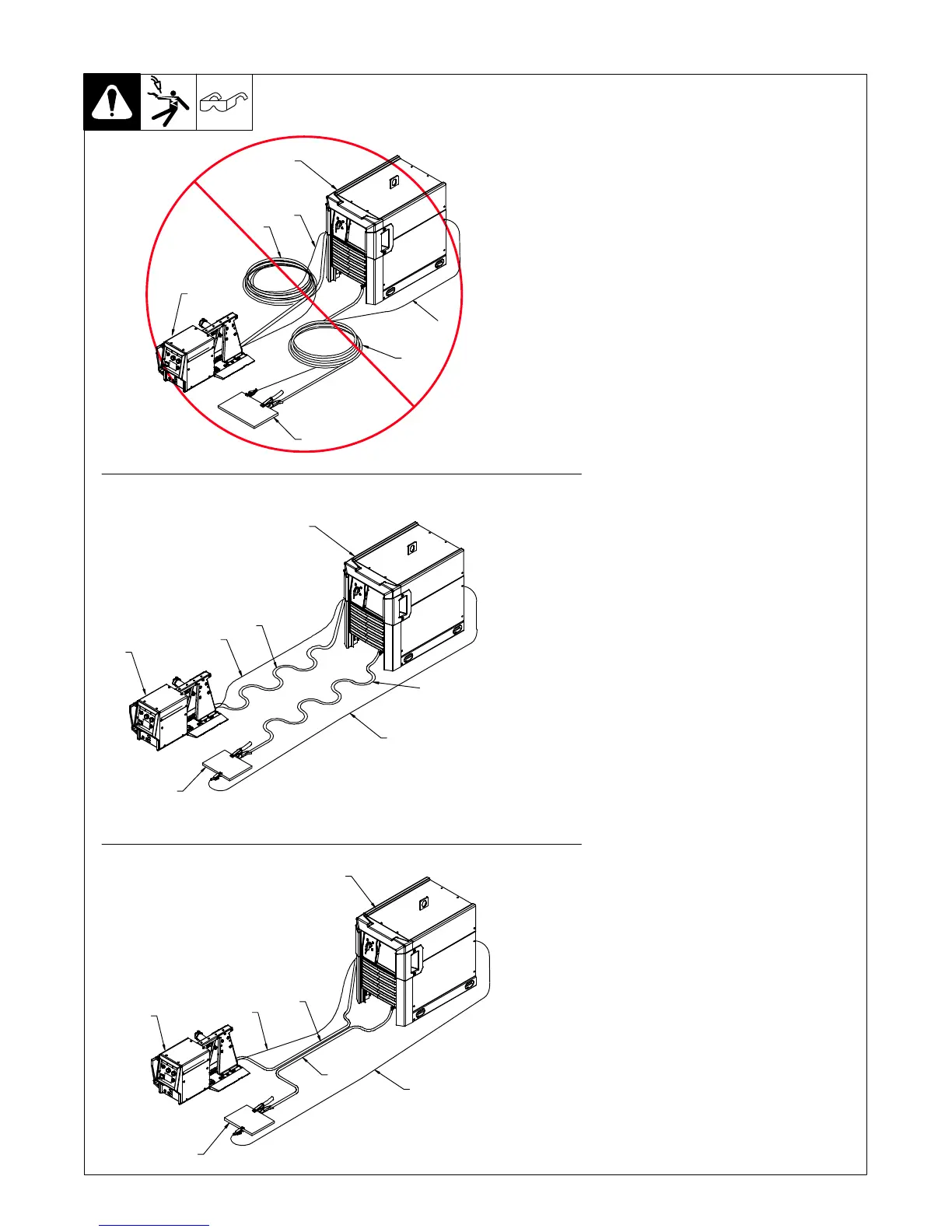

6-2. Arranging Welding Cables To Reduce Welding Circuit Inductance

Bad

Better

Best

1

2

6

5

4

3

7

1

2

3

4

5

6

7

1

5

4

2

3

6

7

Loading...

Loading...