OM-257 798 Page 40

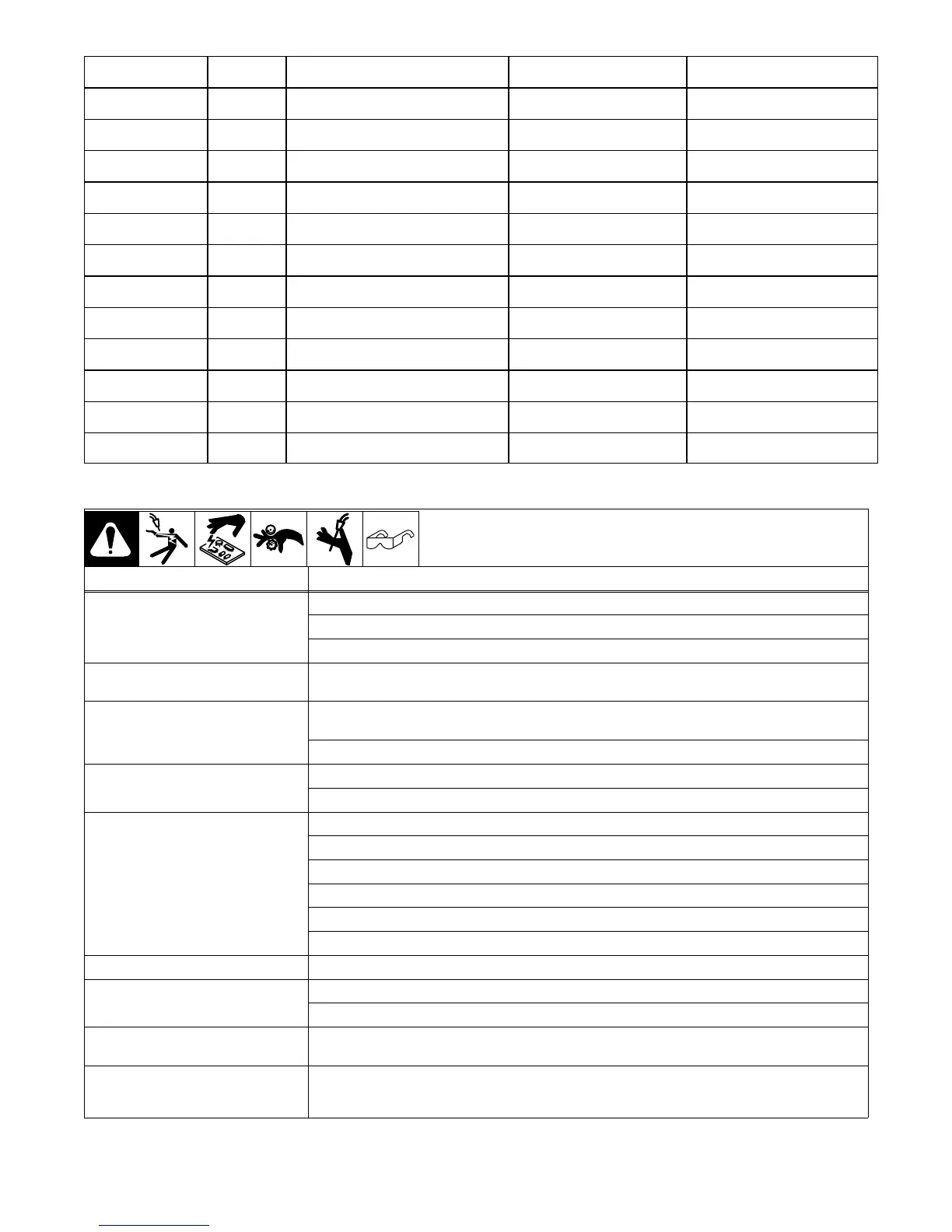

LED Display

Message

Message

Type

LCD Display Message

LCD Solution

Message

LCD Error Log

Message

ERR PWR SRC ERROR Boost current balance error Cycle power on the power

source

Boost Current Balance Error

ERR PWR SRC ERROR Boost overcurrent error Cycle power on the power

source

Boost Overcurrent Error

ERR PWR SRC ERROR Boost precharge error Cycle power on the power

source

Boost Precharge Error

ERR PWR SRC ERROR Boost bus balance error Cycle power on the power

source

Boost Bus Balance Error

ERR PWR SRC ERROR Boost bottom bus cap voltage high Cycle power on the power

source

Boost Bottom Bus Cap V High

ERR PWR SRC ERROR Boost top bus cap voltage high Cycle power on the power

source

Boost Top Bus Cap V High

ERR PWR SRC ERROR Invalid boost device configuration Cycle power on the power

source

Invalid Boost Config

ERR PWR SRC ERROR Boost −15V power supply out of regu-

lation

Cycle power on the power

source

Boost −15V Power Error

ERR PWR SRC ERROR Boost −24V power supply out of regu-

lation

Cycle power on the power

source

Boost −24V Power Error

ERR PWR SRC ERROR Boost +15V power supply out of regu-

lation

Cycle power on the power

source

Boost +15V Power Error

WRN VSNS LOS WARNING Lost volt sense lead feedback Inspect volt sense lead for

break

Vsense Fallback Warning

ERR UNKNOWN ERROR An unknown error has occurred Update software Unknown Error

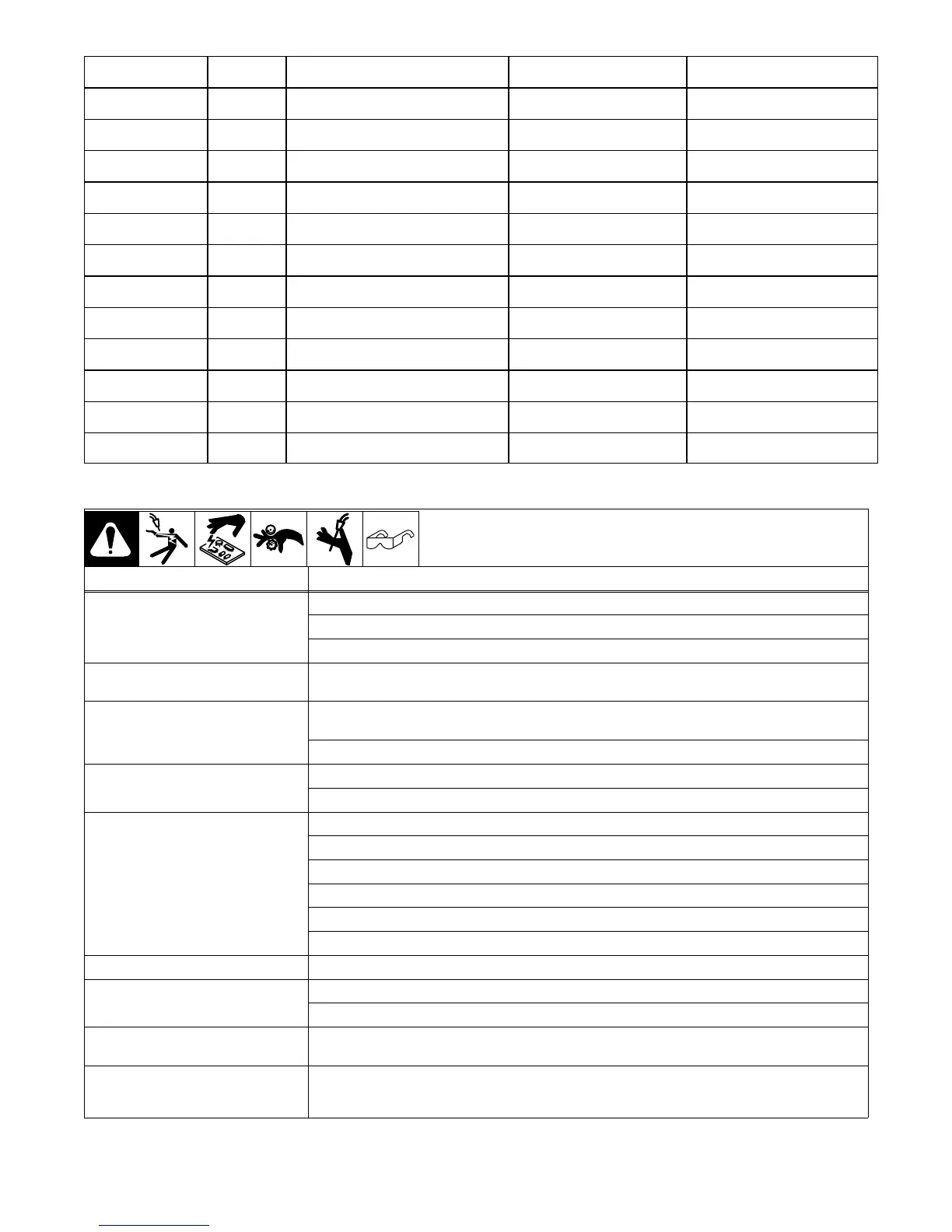

9-4. Troubleshooting

Trouble Remedy

No weld output; completely inoperative Place line disconnect in On position (see Section 5-9).

Check and replace line fuse(s), if necessary, or reset circuit breaker (see Section 5-9).

Check for proper input power connections (see Section 5-9).

No weld output; meter display on with no

error displayed.

Check to see if the contactor indicator light is lit when contactor line is asserted on.

Erratic or improper weld output with no

errors displayed.

Use proper size and type of weld cable (see Section 5-2).

Clean and tighten all weld connections.

Wire does not feed. Check supplementary protector CB1 and reset if necessary.

Check motor control cable connections.

Wire feeds erratically. Readjust hub tension.

Readjust drive roll pressure.

Clean or replace dirty or worn drive rolls.

Remove weld spatter around the nozzle opening.

Replace contact tip or liner. See gun Owner’s Manual.

Check motor control cable connections.

Wire feeds as soon as power is supplied. Check gun trigger. See gun Owner’s Manual.

Wire stubbing on low end using a

constant current power source.

Increase output setting of the power source.

Check voltage sense lead connection, clean and tighten if necessary.

Gas does not flow or does not stop flow-

ing; wire feeds.

Check gas valve and flow meter.

Wire burns back to gun contact tip when

using electrode negative (straight

polarity) process.

Check to be sure that volt sense lead is connected to the work.

Loading...

Loading...