OM-257 798 Page 35

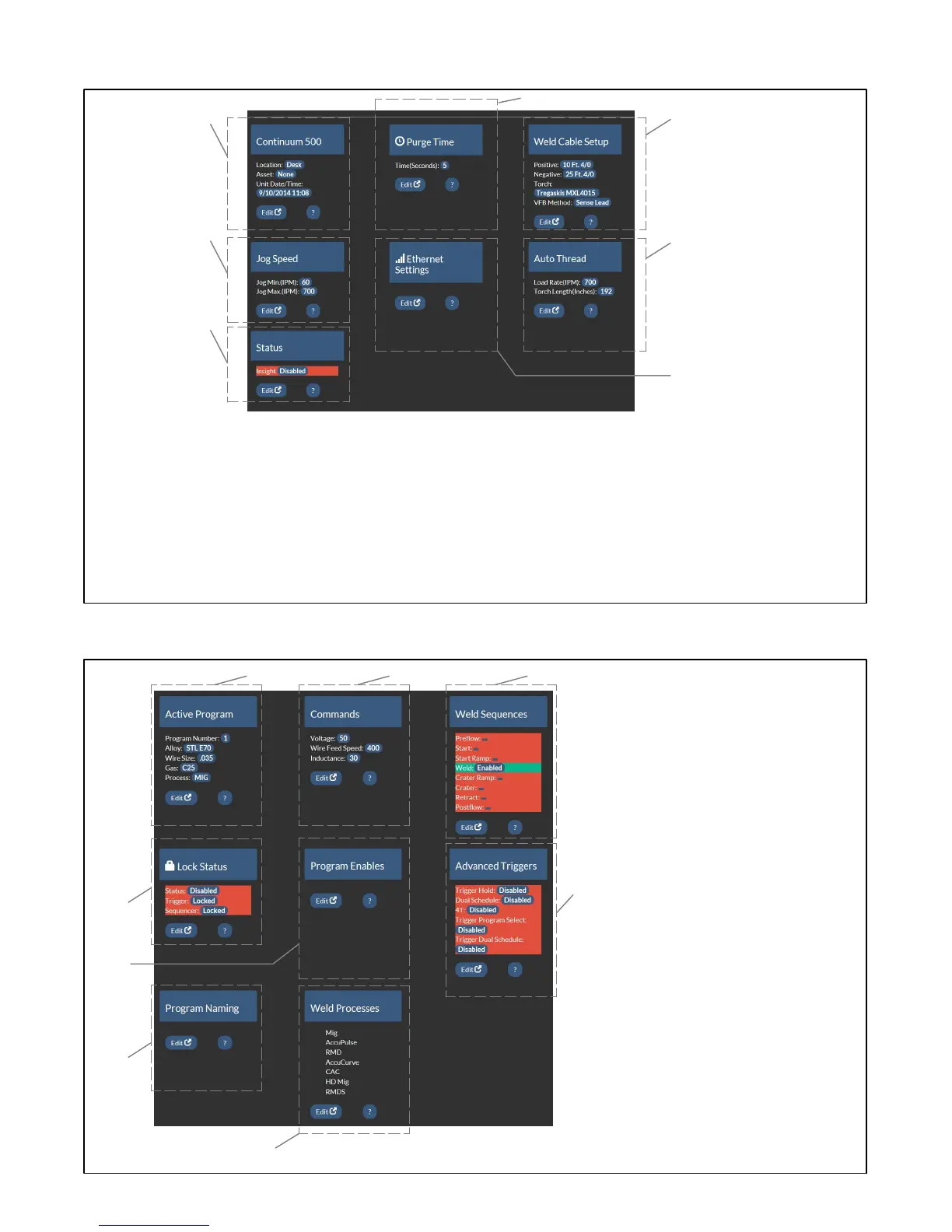

8-3. Setup Screen

1 Information Bar

Displays general information on power source,

location, asset number, serial number, and dis-

play language.

2 Purge Time

Displays the length of time gas will flow when

the purge button is pressed. Edit button allows

time length to be changed.

3 Weld Cable Setup

Displays length and diameter of positive and

negative weld leads, torch, and voltage feed-

back (VFB) method that are selected. Edit but-

ton allows these parameters to be changed.

4 Jog Speed

Displays the minimum and maximum Jog

speeds in inches per minute (IPM). Edit button

allows minimum and maximum jog speed set-

ting to be changed for forward and reverse jog.

5 Ethernet Settings

Edit button allows user to change connectivity

settings.

6 Auto Thread

Displays the Load Rate in inches per minute

(IPM) and Torch Length (Inches) to determine

the length of time for Auto Threading. Edit but-

ton allows these parameters to be changed.

7 Status

Displays the status of Insight software. Edit

button allows that status to be changed.

1

2

5

3

4

7

6

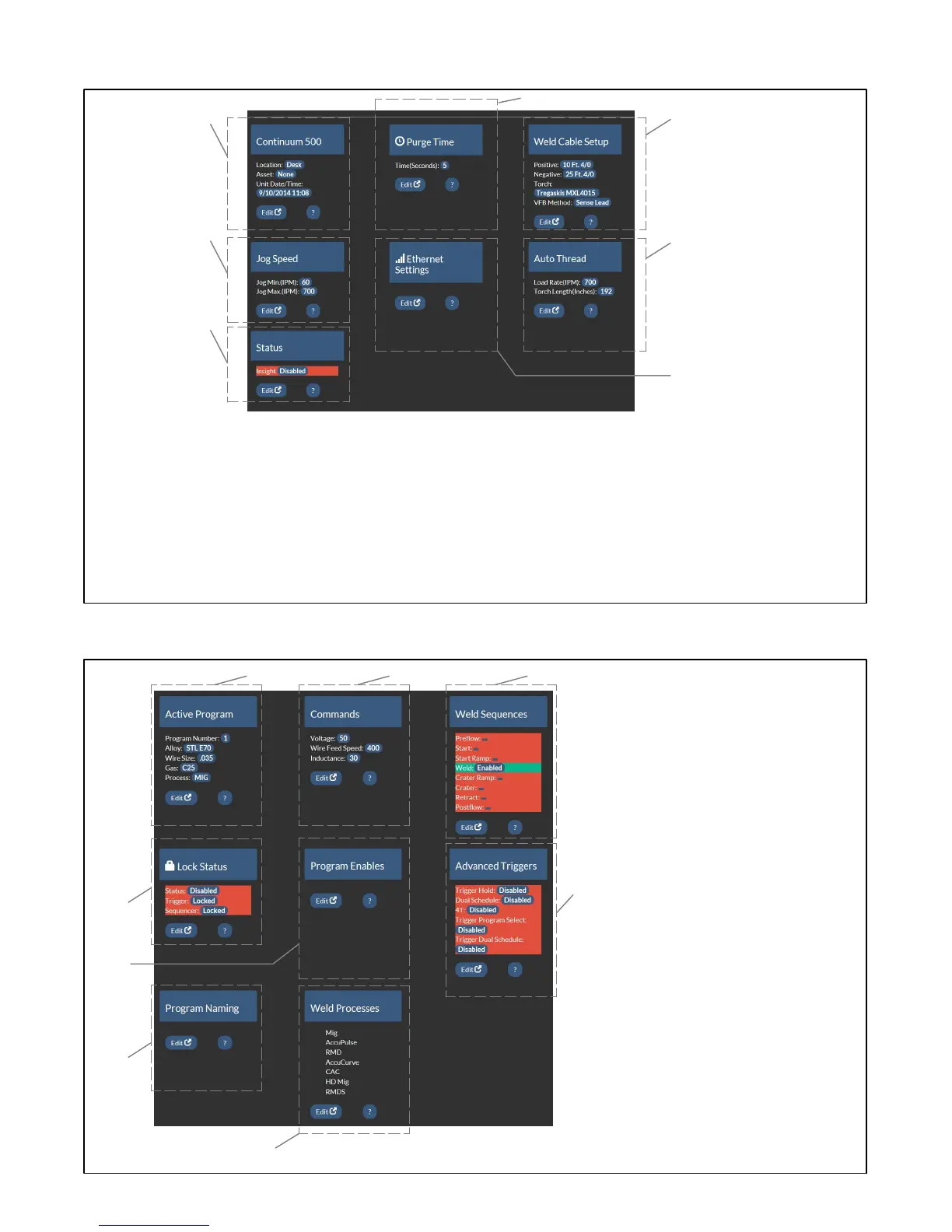

8-4. Arc Management Screen

1 Active Program

Displays the program number, process, wire

size and alloy, and gas. Edit button allows these

parameters to be changed.

2 Commands

Displays current user changeable commands.

Depending on the weld process being used

these commands will vary. Edit button allows pa-

rameters to be changed.

3 Weld Sequence

Displays active weld sequence parameters. Edit

button allows changes to these parameters.

4 Lock Status

Displays the current status of system locks. Edit

button allows the lock configuration to be

changed.

5 Program Enable

Edit button will allow user to select which pro-

grams are available for use.

6 Advanced Triggers

Displays the current status of advanced trigger

modes. Edit button allows status of trigger

modes to be changed.

7 Program Naming

Edit button allows program Machine Display and

Description to be changed for each numbered

program.

8 Weld Processes

Displays available weld processes. Edit button

allows processes to be enabled or disabled.

1

4

2 3

5

6

7

8

Loading...

Loading...